Plane-structure InGaAs array infrared detector

An infrared detector and a planar structure technology, applied in the field of photodetectors, can solve problems such as the difficulty in defining the photosensitive surface, limiting the performance of InGaAs detectors, and large leakage currents, so as to suppress the expansion phenomenon and reduce the expansion phenomenon of the photosensitive surface , the effect of suppressing crosstalk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

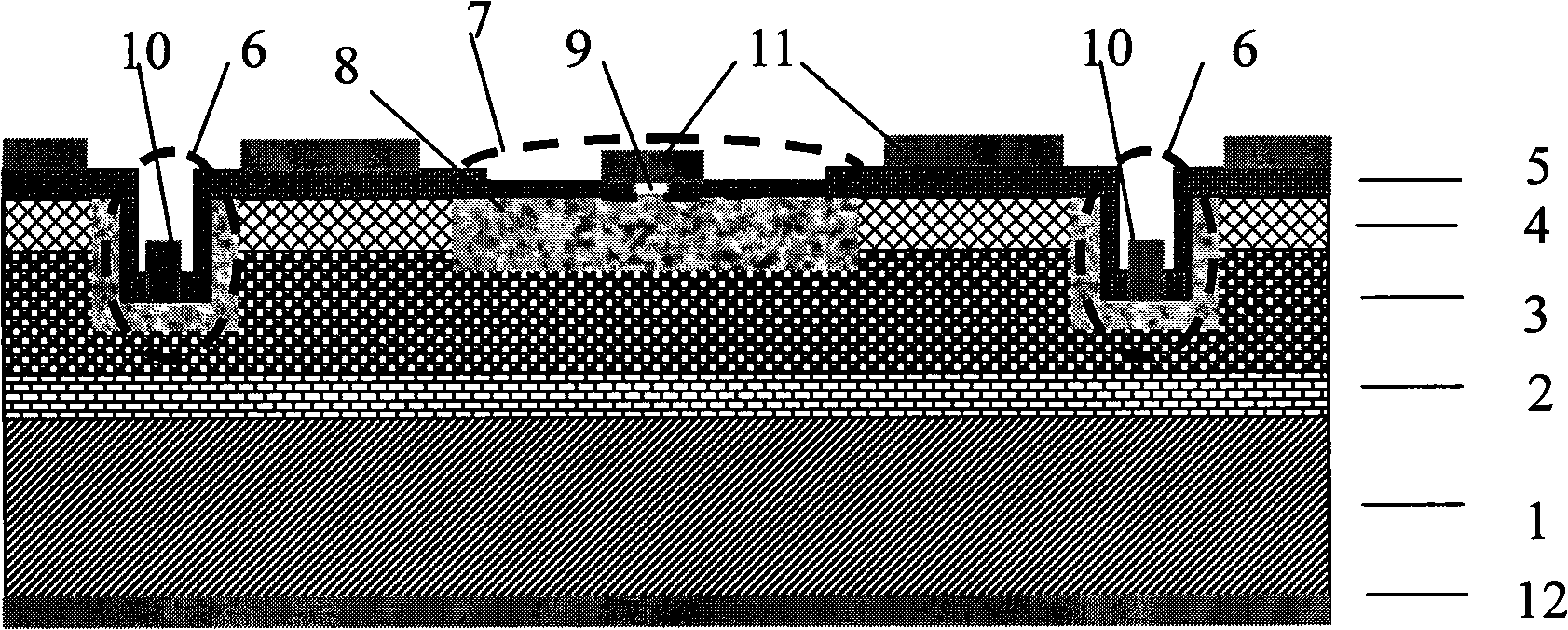

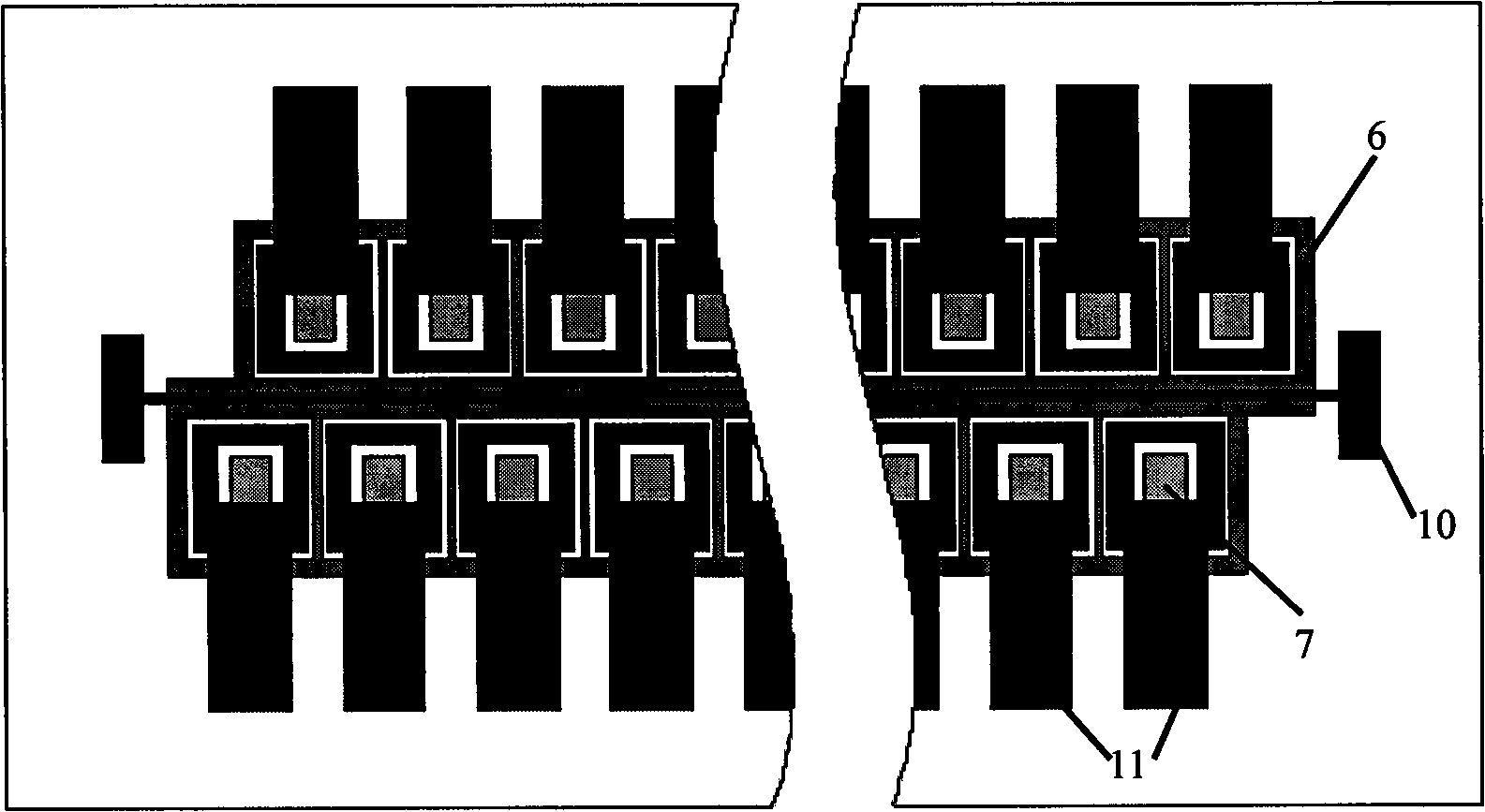

[0012] The specific embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings and examples:

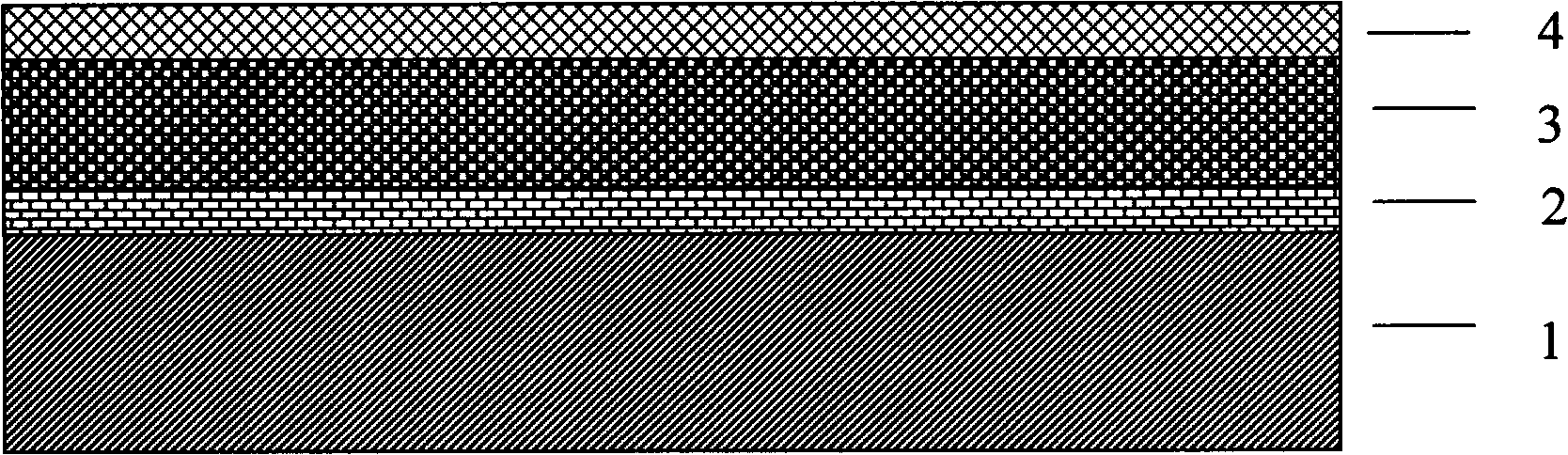

[0013] See figure 1 , the epitaxial wafer used in this embodiment is MOCVD technology with a thickness of 600 μm and a carrier concentration of 3 × 10 18 cm -3 N-type InP layers 2 with a thickness of 1 μm are sequentially grown on the N-InP substrate 1, and the carrier concentration is 2×10 18 cm -3 ; In thickness of 2.5 μm 0.53 Ga 0.47 As intrinsic absorption layer 3, carrier concentration 5×10 16 cm -3 ; N-type InP cap layer 4 with a thickness of 1 μm, carrier concentration 5 × 10 16 cm -3 .

[0014] The device preparation process of this embodiment is as follows:

[0015] 1. Use chloroform, ether, acetone, and ethanol to ultrasonically clean the epitaxial wafer in sequence for more than 2 minutes, and then blow dry with nitrogen;

[0016] 2. Growth of SiO 2 Diffusion mask 5;

[0017] 3. Preparation of S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com