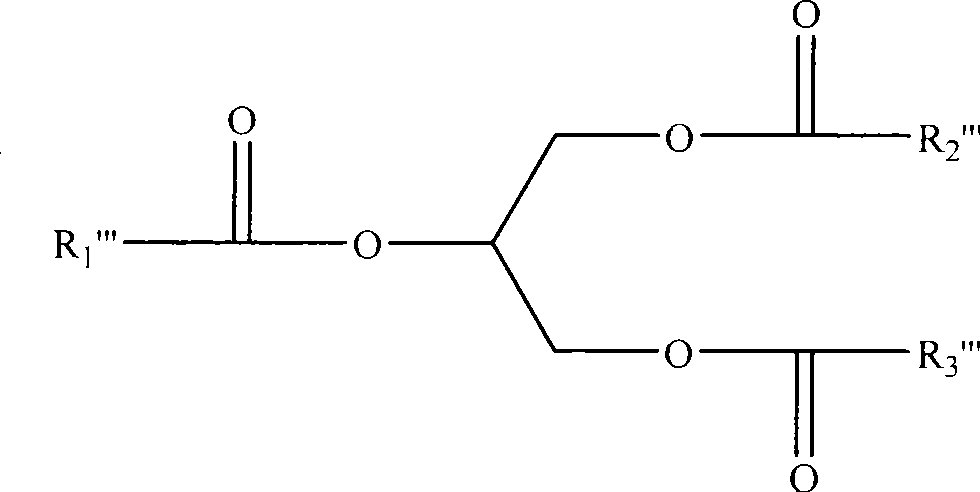

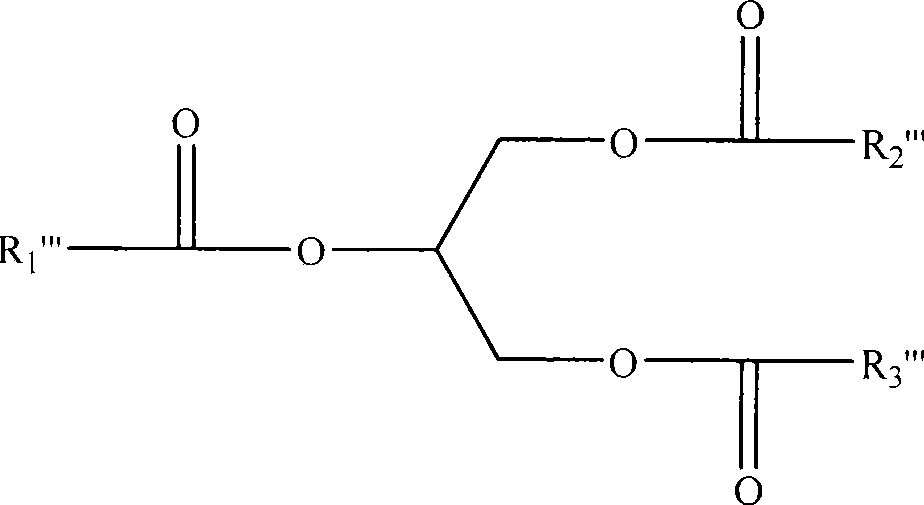

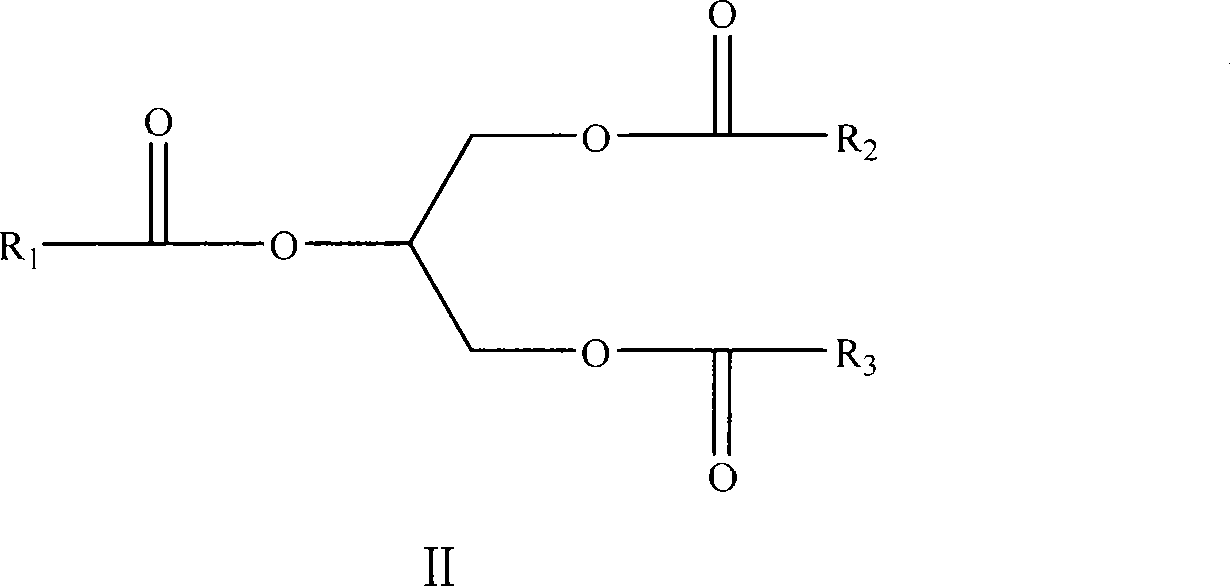

Vegetable oil based anisomeric cyanate radical polyurethane acrylic ester and preparation method thereof

A technology of urethane acrylate and isocyanate, applied in the field of photosensitive polymer materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1) Add 1.8g of tungsten powder into 7g of water, add 15g of 30wt% hydrogen peroxide dropwise during the stirring process, heat to 50°C after the dropwise addition, and stir for 30 minutes. When the tungsten powder is completely dissolved, cool the solution and add 1.38g of 85% hydrogen peroxide Phosphoric acid and 14g water;

[0033] 2) Mix 400g of soybean oil with 2.64g of methyltrialkylammonium chloride, and heat to 50°C under stirring;

[0034] 3) Add the tungsten powder solution in step 1) to the reaction system in step 2), heat to 100°C, stir for 6h, then cool, add 250g of saturated sodium chloride solution and 500g of dichloromethane, and separate the organic layer , washed twice with 250g saturated sodium chloride solution, then dried with anhydrous magnesium chloride, filtered, and the solvent was distilled off under reduced pressure to obtain epoxidized soybean oil derivatives;

[0035] 4) After mixing 200g of epoxidized soybean oil derivatives, 1g of tetrabut...

Embodiment 2

[0039] 1) with step 1) among the embodiment 1;

[0040] 2) Mix 400g of peanut oil with 2.64g of methyltrialkylammonium chloride, and heat to 50°C under stirring;

[0041] 3) to 5) are the same as steps 3) to 5) in Example 1 to obtain hydroxyalkyl carbamate of peanut oil;

[0042]6) Mix and stir 200g of peanut oil-based hydroxyalkyl carbamate, 600g of acrylic acid, 2g of sulfuric acid, 0.2g of hydroquinone and 100g of toluene and heat it up to 110°C. In a boiling state, toluene will bring the water obtained from the esterification reaction to the separation In the water tank, when there is no more water coming out, the esterification reaction is over, under reduced pressure, heat to 90 ° C, distill off the water-carrying agent and excess unreacted acrylic acid, and obtain peanut oil-based non-isocyanato polyurethane acrylate .

Embodiment 3

[0044] 1) with step 1) among the embodiment 1;

[0045] 2) Mix 400g corn oil with 2.64g methyltrialkylammonium chloride, and heat to 50°C under stirring;

[0046] 3) to 5) are the same as steps 3) to 5) in Example 1 to obtain hydroxyalkyl carbamate;

[0047] 6) Mix and stir 200g of corn oil-based hydroxyalkyl carbamate, 600g of acrylic acid, 2g of p-toluenesulfonic acid, 0.2g of p-hydroxyanisole and 100g of toluene and heat it to 110°C. In a boiling state, toluene will undergo esterification reaction to obtain The water is taken to the water separator, when no more water comes out, the esterification reaction is over, under reduced pressure, it is heated to 90°C, and the water-carrying agent and excess unreacted acrylic acid are distilled off to obtain corn oil-based non- Isocyanato urethane acrylate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com