Preparation method for temperature sensitive response type intelligent ceramic composite membrane and product

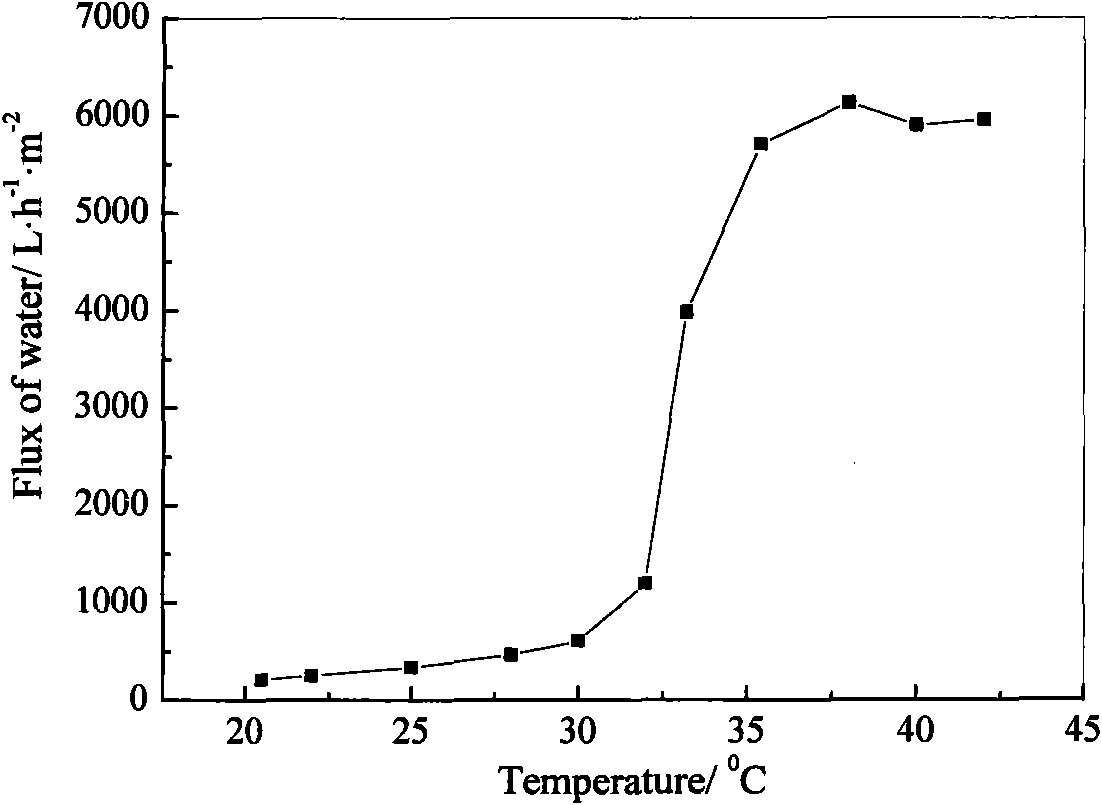

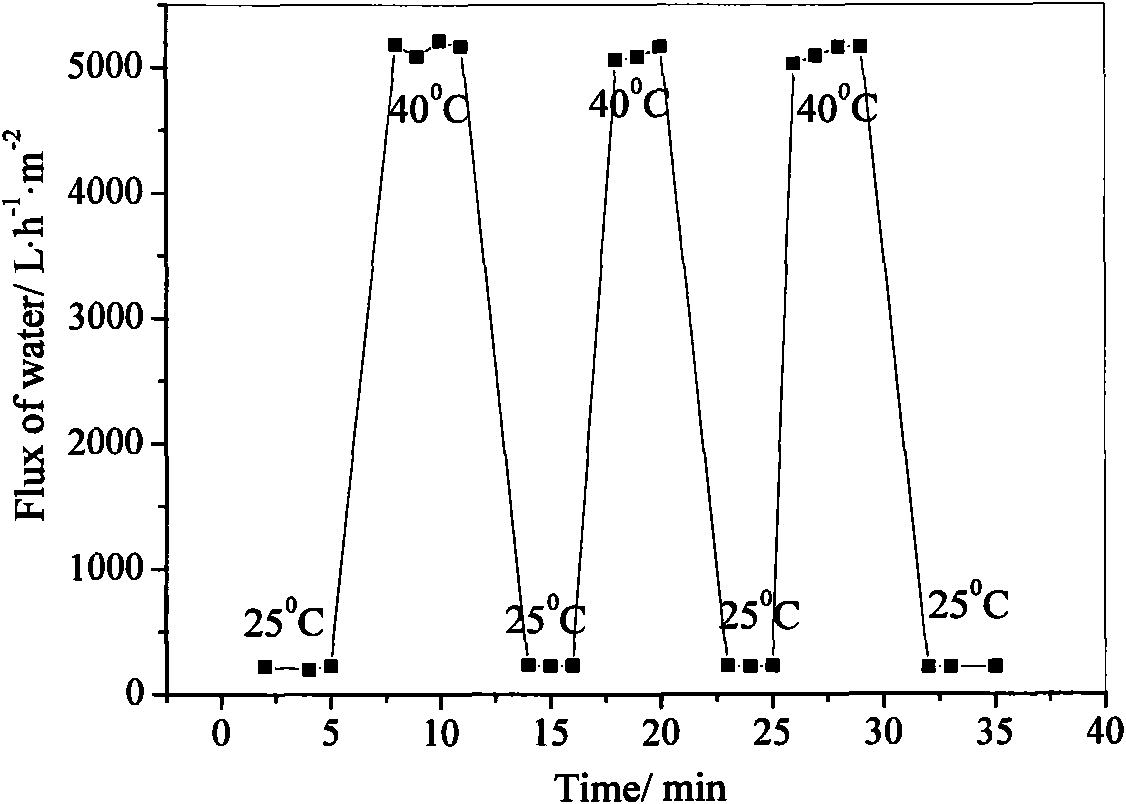

A ceramic composite membrane and ceramic membrane technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problem of low mechanical strength and achieve high mechanical strength, large permeation flux, and good stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The temperature-sensitive and responsive smart ceramic composite membrane was prepared according to the following steps:

[0026] (1) Acid treatment membrane: the α-Al 2 o 3 The membrane is immersed in an aqueous solution with a pH of 3 for 24 hours, and then the membrane is dried in an oven at 70°C for 12 hours to ensure that there is a certain amount of bound water on the surface of the membrane; the acid solution is HCl solution;

[0027] (2) Silanization modification of the membrane: add acid-treated α-Al to the conical flask 2 o 3 Ceramic diaphragm (specific surface area 6.15cm 2 ) and a toluene solution with a mass concentration of 5% KH-570, ultrasonically oscillated to make it dissolve evenly, and the temperature was refluxed at 80°C for reaction; after the reaction, the membrane was cleaned, and the cleaned membrane was first dried at room temperature, and then heated at 120°C down dry;

[0028] (3) Preparation of composite membrane: put 0.05g of potassium...

Embodiment 2

[0030] (1) with embodiment 1, wherein acid solution is HNO 3 solution, where the diaphragm is ZrO 2 Diaphragm;

[0031] (2) Silanization modification of the film: adding acid-treated ZrO in the conical flask 2 Ceramic diaphragm and toluene solution containing 15% KH-570, ultrasonically oscillated to dissolve evenly, and reflux reaction at 80°C; after the reaction, the diaphragm was cleaned, and the cleaned diaphragm was first dried at room temperature, and then dried at 120 Dry at ℃;

[0032] (3) Preparation of composite membrane: put 0.025g of potassium persulfate and 20ml of deionized water into the reactor, ultrasonically dissolve them evenly, then add 0.75g of N-isopropylacrylamide monomer, feed in nitrogen and change the above Add a permanent ceramic diaphragm, heat to 80°C, and react with constant temperature oscillation for 30 minutes; then ultrasonically clean it with deionized water several times, and dry the obtained diaphragm in a vacuum oven at 60°C to obtain a ...

Embodiment 3

[0034] (1) with embodiment 1, wherein diaphragm is SiO 2 Diaphragm;

[0035] (2) Silanization modification of the film: SiO after acid treatment was added to the conical flask 2 Ceramic diaphragm and toluene solution containing 10% KH-570, ultrasonically oscillated to dissolve evenly, and reflux reaction at 80°C; after the reaction, the diaphragm was cleaned, and the cleaned diaphragm was first dried at room temperature, and then dried at 120 Dry at ℃;

[0036] (3) Preparation of composite membrane: put 0.1g potassium persulfate and 50ml deionized water into the reactor, ultrasonically dissolve them evenly, then add 0.5g N-isopropylacrylamide monomer, feed nitrogen gas and change the above Add a non-toxic ceramic diaphragm, heat to 60°C, and oscillate at a constant temperature for 100 minutes; then ultrasonically clean it several times with deionized water, and dry the obtained diaphragm in a vacuum oven at 60°C to obtain a temperature-sensitive and responsive intelligent ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com