Enyl phenol refining plant and method thereof

A technology of o-phenylphenol and refining method, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

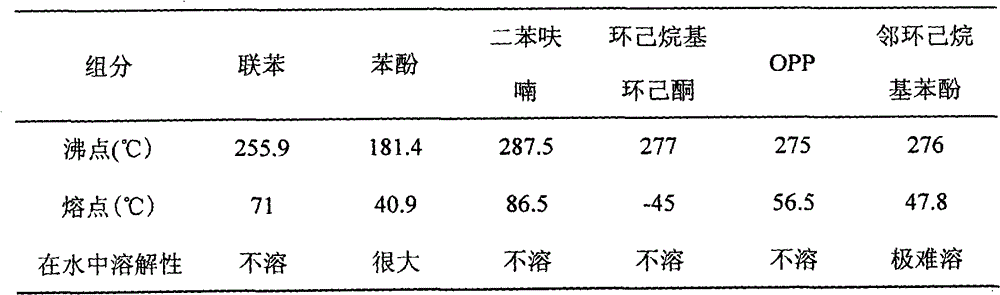

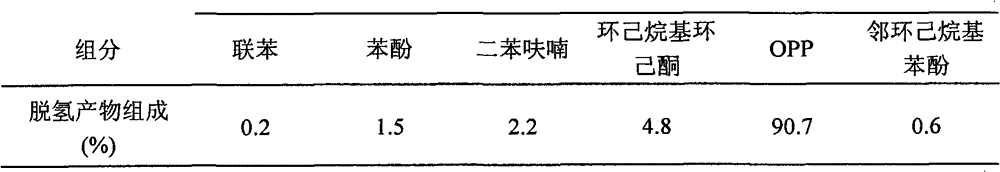

[0031] The composition of the dimer-cyclohexenylcyclohexanone obtained by condensation and dehydration of cyclohexanone through catalytic dehydrogenation is shown in the following table.

[0032]

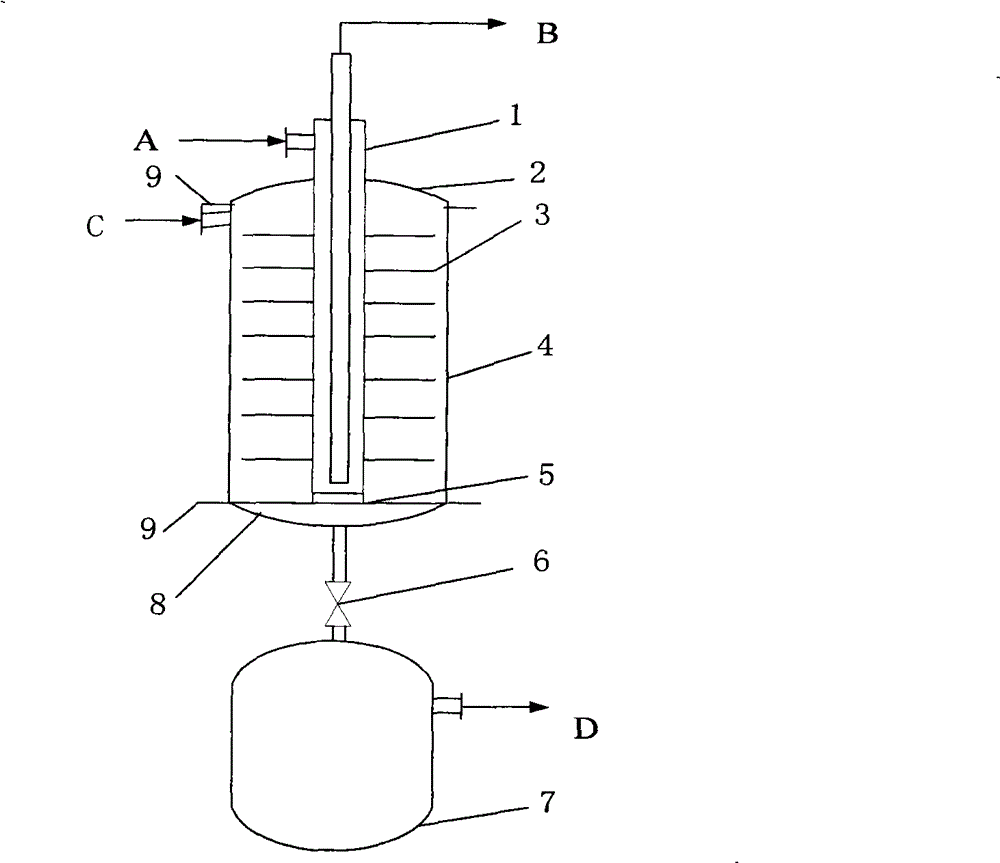

[0033] Such as figure 1 Shown: "Sweating" crystallizer diameter DN120, height 150mm; finger tube inner tube diameter DN25mm, outer tube diameter DN40mm, fins circular, diameter DN100mm, sheet spacing 50mm; finger tube welding On the upper head of the crystallization tank, the flange is connected to the upper flange of the crystallization tank body; the lower flange of the crystallization tank body is connected to the flange of the lower head. There are filter plates and filter cloths between the flanges, and there are Asbestos insulation. The crystallization tank and the suction filter tank are connected together with a valve.

[0034]Add 1200g of the dehydrogenation product into this "sweating" crystallizer, pass water at 28°C into the finger tube for 1 hour to crystallize th...

Embodiment 2

[0039] In the same OPP "sweating" crystallization system as in Example 1 and using the same dehydrogenation product composition and different "sweating" crystallization conditions, the results are shown in Table 1.

[0040] Table 1 OPP continuous refining results

[0041]

[0042] Table 2 Melt composition table

[0043]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com