Collagen-based composite cornea substitute with bioactivity and preparation method thereof

A bioactive and substitute technology, applied in eye implants, medical science, prostheses, etc., can solve problems such as easy hydrolysis, MPC easy to absorb moisture, etc., achieve good tissue compatibility, promote enrichment, and improve stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

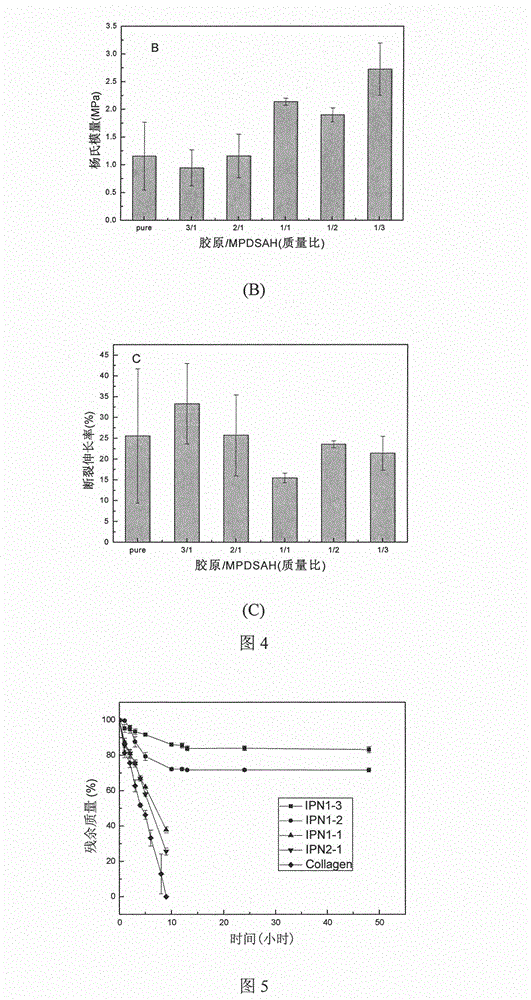

Embodiment 1

[0032] The ratio of each component of the bioactive composite corneal substitute is as follows:

[0033] Pig skin type I collagen: MPDSAH (mass ratio) 3:1

[0034] MPDSAH: PEGDA (mass ratio) 2:1

[0035]Collagen: EDC: NHS (molar ratio) 1:1:1

[0036] The steps of preparing the bioactive composite corneal substitute with the above-mentioned components are as follows:

[0037] (1) Preparation of composite corneal substitute: get 0.5g of 13.7% pigskin type I collagen solution into a syringe, and connect another syringe through a T-shaped container to seal; take MPDSAH with a mass ratio of 1:3 to collagen and dissolve it in In water, use a microsyringe to move into the T-shaped container through the sealing gasket, repeatedly push and pull to mix evenly, and then use a microsyringe to inject the cross-linking agent EDC, NHS and photoinitiator Irgacure 2959 in sequence, wherein EDC:NHS:collagen=1:1:1( molar ratio), initiator Irgacure2959:MPDSAH=1:25 (molar ratio), push and pull ...

Embodiment 2

[0041] The ratio of each component of this biologically active composite corneal substitute is as follows:

[0042] Pig skin type I collagen: MPDSAH (mass ratio) 2:1

[0043] MPDSAH: PEGDA (mass ratio) 2:1

[0044] Collagen: EDC: NHS (molar ratio) 1:1:1

[0045] The steps of preparing the bioactive composite corneal substitute with the above-mentioned components are as follows:

[0046] (1) Preparation of composite corneal substitute: get 0.5g of 13.7% pigskin type I collagen solution into a syringe, and connect another syringe through a T-shaped container to seal; take MPDSAH with a mass ratio of 1:2 to collagen and dissolve in In water, use a microsyringe to move into the T-shaped container through the sealing gasket, repeatedly push and pull to mix evenly, and then use a microsyringe to inject the cross-linking agent EDC, NHS and photoinitiator Irgacure 2959 in sequence, wherein EDC:NHS:collagen=1:1:1( molar ratio), initiator Irgacure2959:MPDSAH=1:25 (molar ratio), push ...

Embodiment 3

[0050] The ratio of each component of this biologically active composite corneal substitute is as follows:

[0051] Pig skin type I collagen: MPDSAH (mass ratio) 1:1

[0052] MPDSAH: PEGDA (mass ratio) 2:1

[0053] Collagen: EDC: NHS (molar ratio) 1:1:1

[0054] The steps of preparing the bioactive composite corneal substitute with the above-mentioned components are as follows:

[0055] (1) Preparation of composite corneal substitute: get 0.5g of 13.7% pigskin type I collagen solution into a syringe, and connect another syringe through a T-shaped container to seal; take MPDSAH with a mass ratio of 1:1 to collagen and dissolve In water, use a microsyringe to move into the T-shaped container through the sealing gasket, repeatedly push and pull to mix evenly, and then use a microsyringe to inject the cross-linking agent EDC, NHS and photoinitiator Irgacure 2959 in sequence, wherein EDC:NHS:collagen=1:1:1( molar ratio), initiator Irgacure2959:MPDSAH=1:25 (molar ratio), push and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com