Method suitable for utilization of resource of sintering flue gas desulphurization waste solution

A technology for desulfurization waste liquid and sintering flue gas, applied in chemical instruments and methods, separation methods, inorganic chemistry, etc., can solve the problems of a large number of site stacking, secondary pollution, low utilization rate of desulfurization products, etc., and reduce the overall operating cost. , high quality, and the effect of realizing environmental protection benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

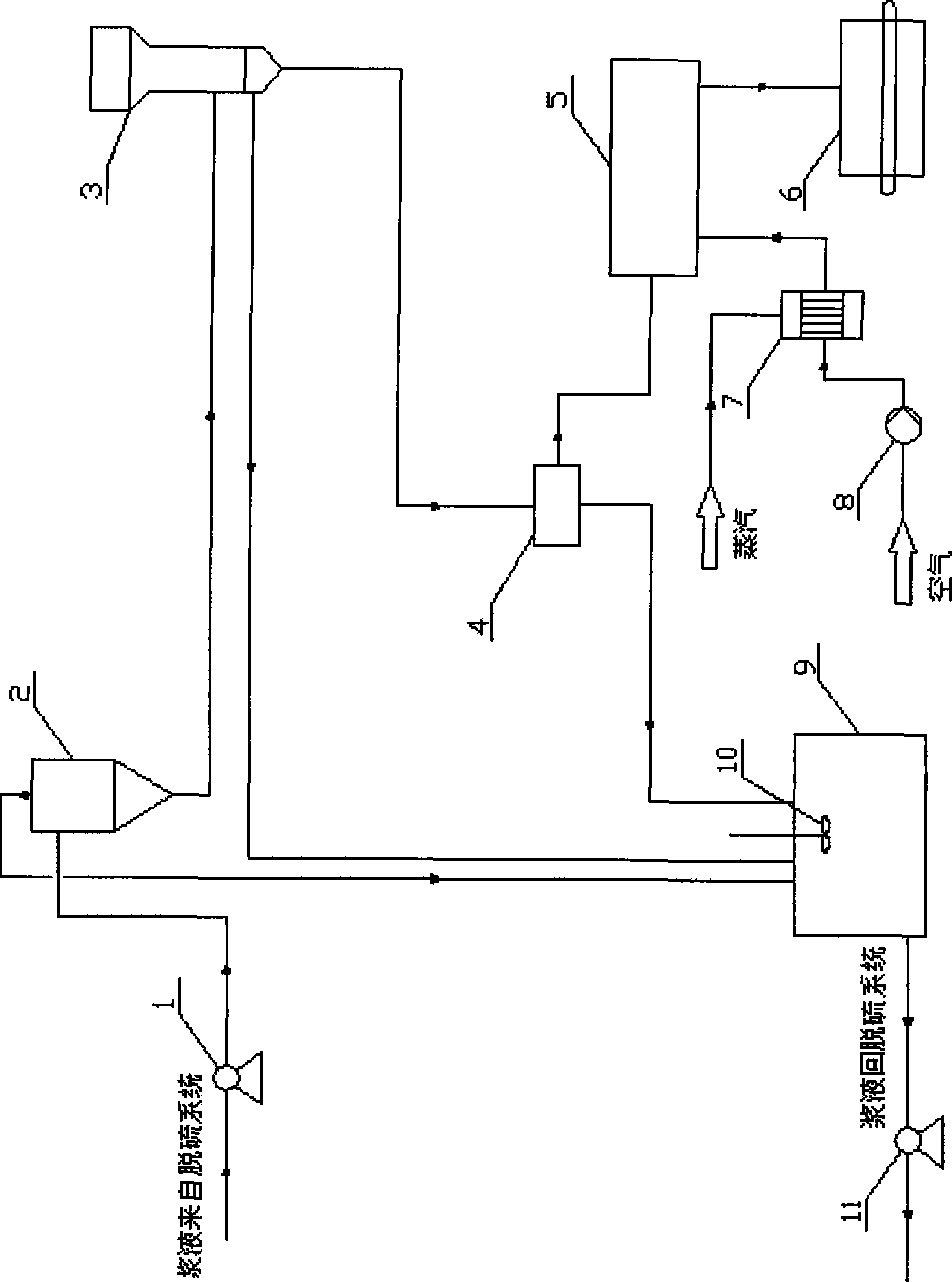

[0024] a) The desulfurization waste liquid is delivered to the cyclone separator 2 by the ammonium sulfate slurry pump 1 and the pipeline system;

[0025] b) The slurry reaches partial solid-liquid separation in the cyclone separator, and the upper part contains a low-concentration ammonium sulfate solution that is transported to the ammonium sulfate feed liquid tank 9 through a pipeline, and the high-concentration ammonium sulfate solution in the lower part is transported to the thickener 3 through a pipeline ;

[0026] c) the high-solid ammonium sulfate solution thickened by the thickener 3 enters the centrifuge 4 through the overflow pipe at the bottom of the thickener;

[0027] d) the ammonium sulfate slurry continues solid-liquid separation in the centrifuge 4 to obtain ammonium sulfate particles with a water content lower than 5%, and the ammonium sulfate mother liquor enters the ammonium sulfate feed liquid tank 9;

[0028] E) ammonium sulfate granule enters drier 5, d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com