Method for manufacturing medium density fiberboard with enzyme-activated fiber

A technology of fiberboard and medium density, which is applied in the direction of manufacturing tools, flat products, and pretreatment of molding materials. It can solve the problems of large water consumption, insufficient internal bonding strength, and low activation efficiency, so as to reduce water consumption and facilitate industrial production. , the effect of reducing processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

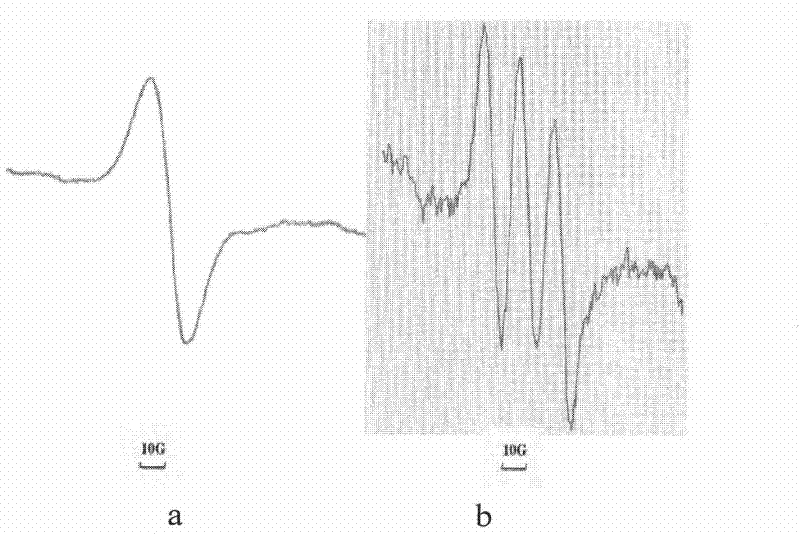

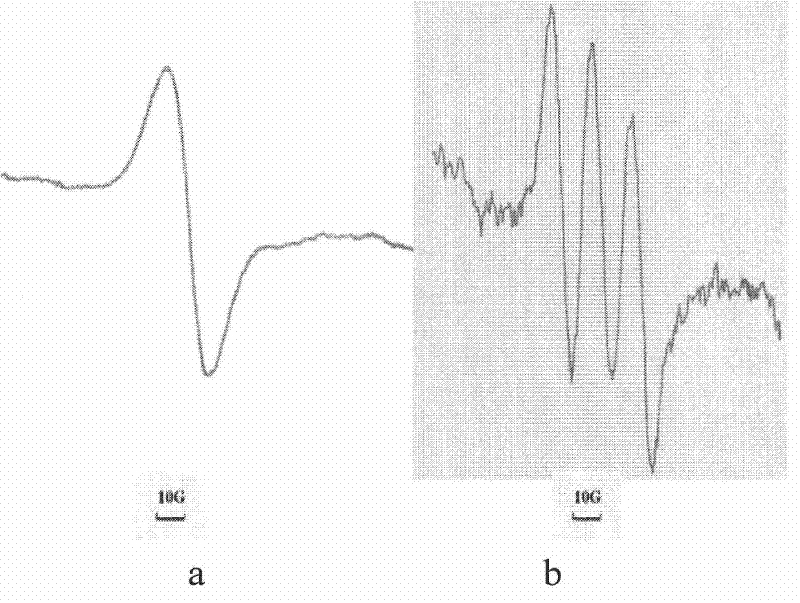

Image

Examples

Embodiment 1

[0015] (1) Enzyme solution preparation: Laccase (Laccase EC 1.10.3.2) with an amount of 30U / (g dry fiber) was added to acetic acid / sodium acetate buffer solution with a pH of 5.0 and mixed evenly, and the quality of the buffer was controlled so that all the enzyme solution was added The moisture content of poplar fiber is 55%, and the target density of fiberboard is 0.80g / cm 3 , The plate thickness is 3mm. The enzyme used is laccase Novo Nordisk A / S, Novozym51003 (EC 1.10.3.2), and the substrate used when measuring laccase activity is the ethanol solution of syringaldazine (syringaldazine), and the specific activity of the laccase enzyme solution used in the test is 3U / ml, an enzyme activity unit (U) refers to the amount of enzyme required to catalyze the conversion of 1 μmol of syringaldazine into a product per minute under certain reaction conditions;

[0016] (2) Enzyme-activated fiber: the poplar is dried to a moisture content of 10% after slicing, washing, heat grinding,...

Embodiment 2

[0020] (1) Enzyme solution preparation: Laccase (Novozym 51003) with an amount of 30U / (g dry fiber) was added to acetic acid / sodium acetate buffer solution with a pH of 4.5 and mixed evenly. The moisture content of the fiber is 50%, and the target density of the fiberboard is 0.85g / cm 3 , the plate thickness is 3mm, and the specific activity of the laccase enzyme solution used in the test is 3U / ml;

[0021] (2) Enzyme-activated fiber: the poplar is dried to a moisture content of 10% after slicing, washing, heat grinding, and fiber separation to obtain poplar fiber; the prepared enzyme solution is sprayed on the poplar fiber by a glue mixer, and then the fiber is Transfer to ventilation and drying equipment for activation treatment at 55°C and dry the fiber for 60 minutes, so that the moisture content of the fiber is 13-16%;

[0022] (3) Hot pressing: manual paving, using a hot pressing process with a temperature of 200°C, a time of 90 s / mm, and a hot pressing pressure of 2.5 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com