Polypropylene composite material containing potassium titanate crystal whiskers and wood powder

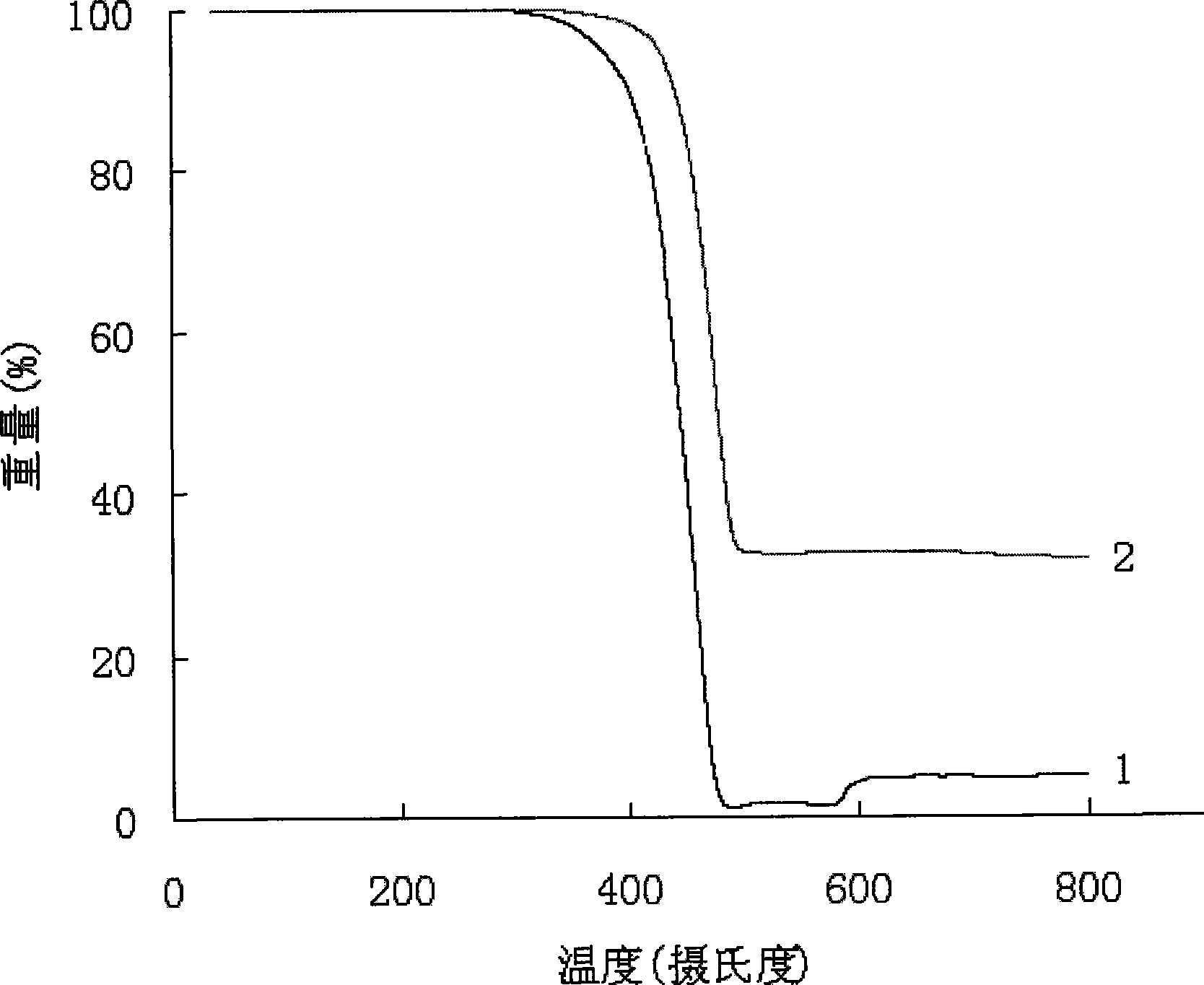

A technology of potassium titanate whiskers and potassium hexatitanate whiskers, which is applied in the field of polypropylene modification, can solve the problems of low tensile strength and impact performance, large shrinkage, etc., and achieve good compatibility, lower viscosity, and insulation The effect of excellent thermal performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Isotactic polypropylene PP is used as the matrix, PP-g-MAH (maleic anhydride grafted polypropylene) is added as a compatibilizer, and wood powder and potassium hexatitanate whiskers are used as reinforcing agents; the wood powder is heated at 80°C For drying, the potassium hexatitanate whiskers were treated with n-butyl titanate and then dried in an oven. Then wood powder, inorganic filler, toughening agent, wax powder and other additives are mixed in a mixer, and then granulated in an extruder, and potassium hexatitanate whiskers are added through a side feed port. Test coupons were then injection molded to measure properties. Its blend component content is as follows (by weight):

[0031] Isotactic polypropylene PP 650

[0032] Wood flour 150

[0033] Potassium hexatitanate whiskers 75

[0034] Compatibilizer PP-g-MAH 100

[0035] n-butyl titanate coupling agent 3

[0036] Inorganic filler 50

[0037] Toughener (POE) 50

[0038] Wax powder (Honeywell) 5

[00...

Embodiment 2~6

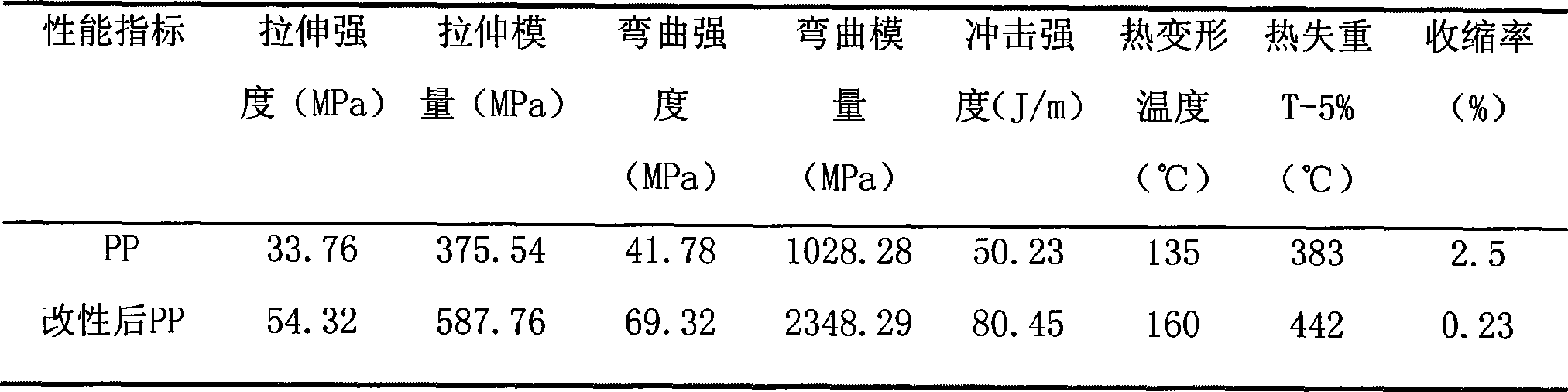

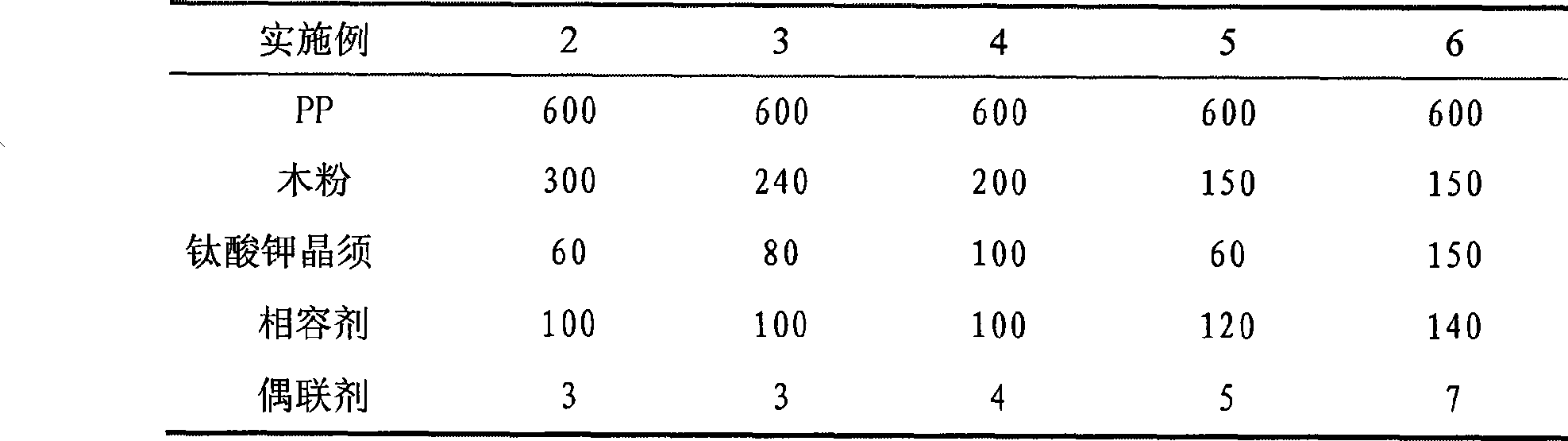

[0045] In the following examples, the preparation method of the polypropylene composite material is the same as Example 1, and the different compositions used are shown in Table 3.

[0046] Table 2 Polypropylene composite material components of Examples 2-6 (by weight)

[0047]

[0048]

[0049] Table 3 Performance indicators of polypropylene composite materials in Examples 2 to 6

[0050]

[0051]It can be seen from Example 2 that when the ratio of wood flour to potassium titanate whiskers is 5:1, the performance of the polypropylene composite material is not greatly improved, while when the ratio of wood flour to potassium titanate whiskers is 1:1 (Example 6), and when the potassium titanate whisker content is greater than 10%, because too much potassium titanate is easy to agglomerate, the performance of the polypropylene composite material has not been greatly improved, and the cost is relatively high. When the ratio of wood flour to potassium titanate whiskers i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com