Vacuum auxiliary-solvent evaporation interface combined with two-dimensional liquid chromatography

A vacuum-assisted liquid chromatography technology, applied in the field of two-dimensional liquid chromatography, can solve problems affecting the second-dimensional separation efficiency, peak shape distortion, and band broadening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

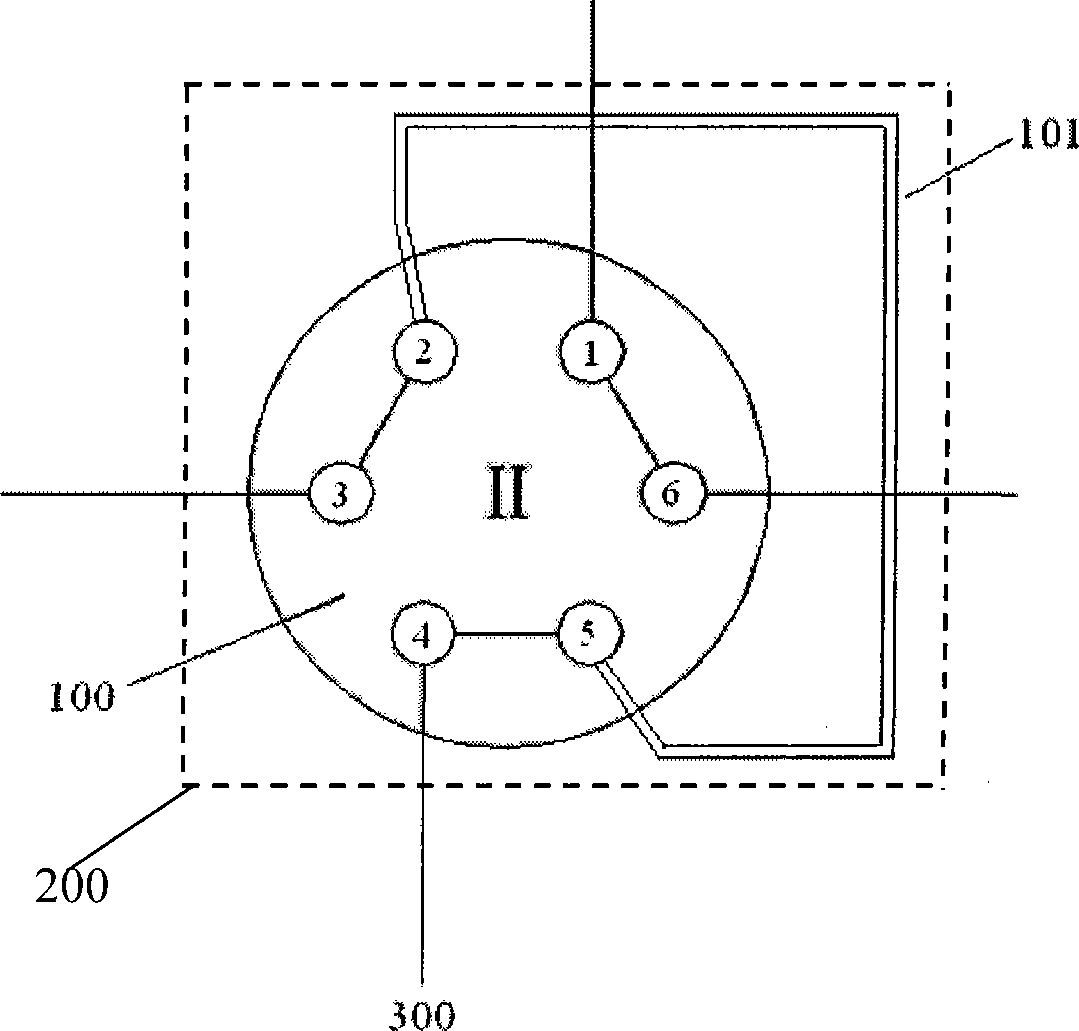

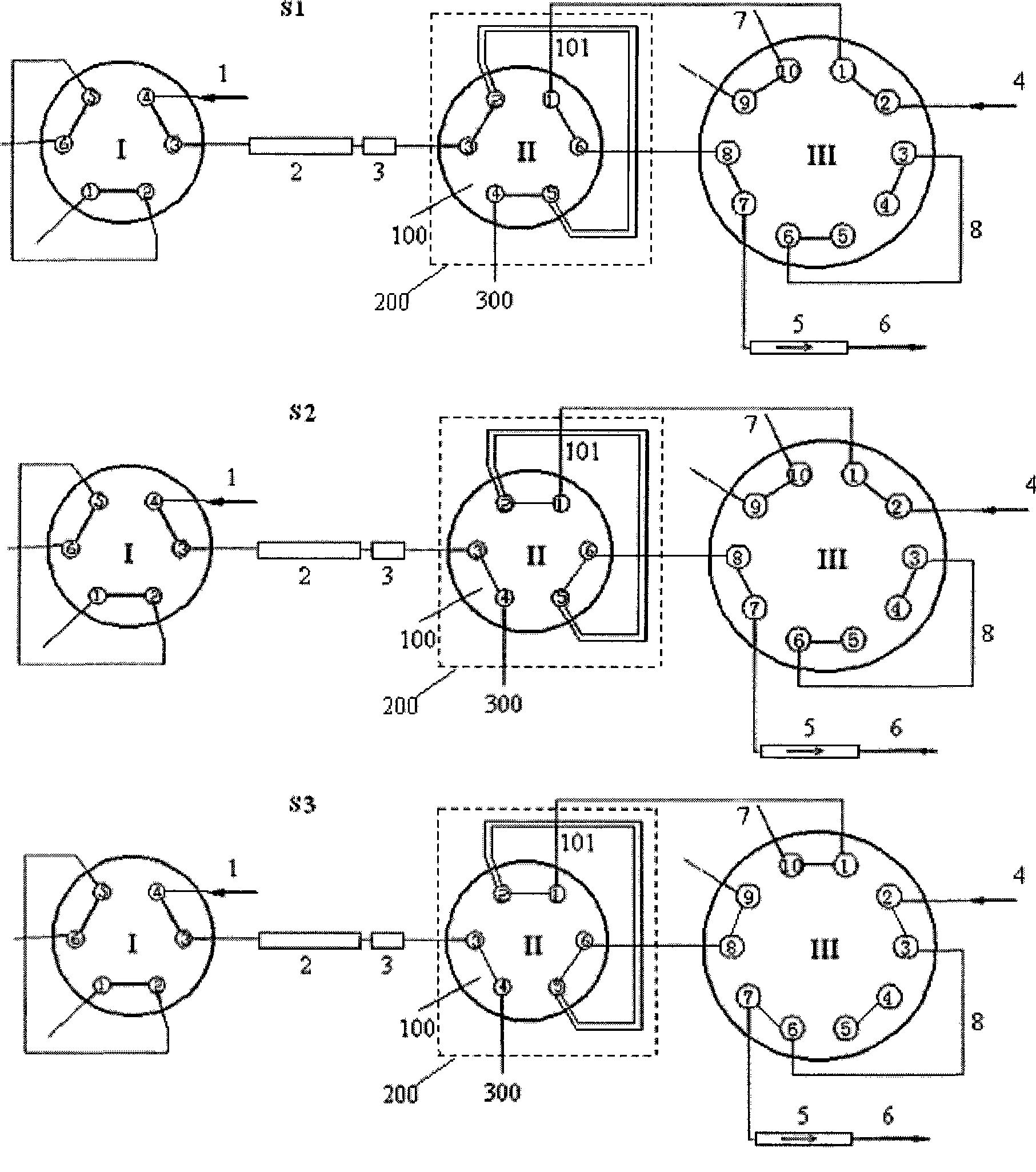

[0027] Experimental device such as figure 2 Shown, with high-pressure liquid chromatography pump as the first dimension infusion pump, the first six-way valve 1 is as the first dimension liquid chromatography sampling valve, and the first dimension chromatographic column uses the cyano group stationary phase column, and column size is ( 250 mm x 4.6 mm i.d., 5 μm) with an ultraviolet-visible absorptiometry (UV-Vis) detector as the detector for the first dimension chromatography. Use another six-way valve 100 as an interface valve, and the evaporation quantitative tube connected to it is a 120mm×1.0mm i.d. stainless steel tube. A constant temperature water bath is used to realize the constant temperature of the evaporation quantitative tube. 1Pa, pumping speed 2L / s) to evacuate the evaporation quantitative tube. A high performance liquid chromatograph with UV-Vis detector is used as the second dimension liquid chromatographic system. A ten-way valve (III) is used as a switch...

Embodiment 2

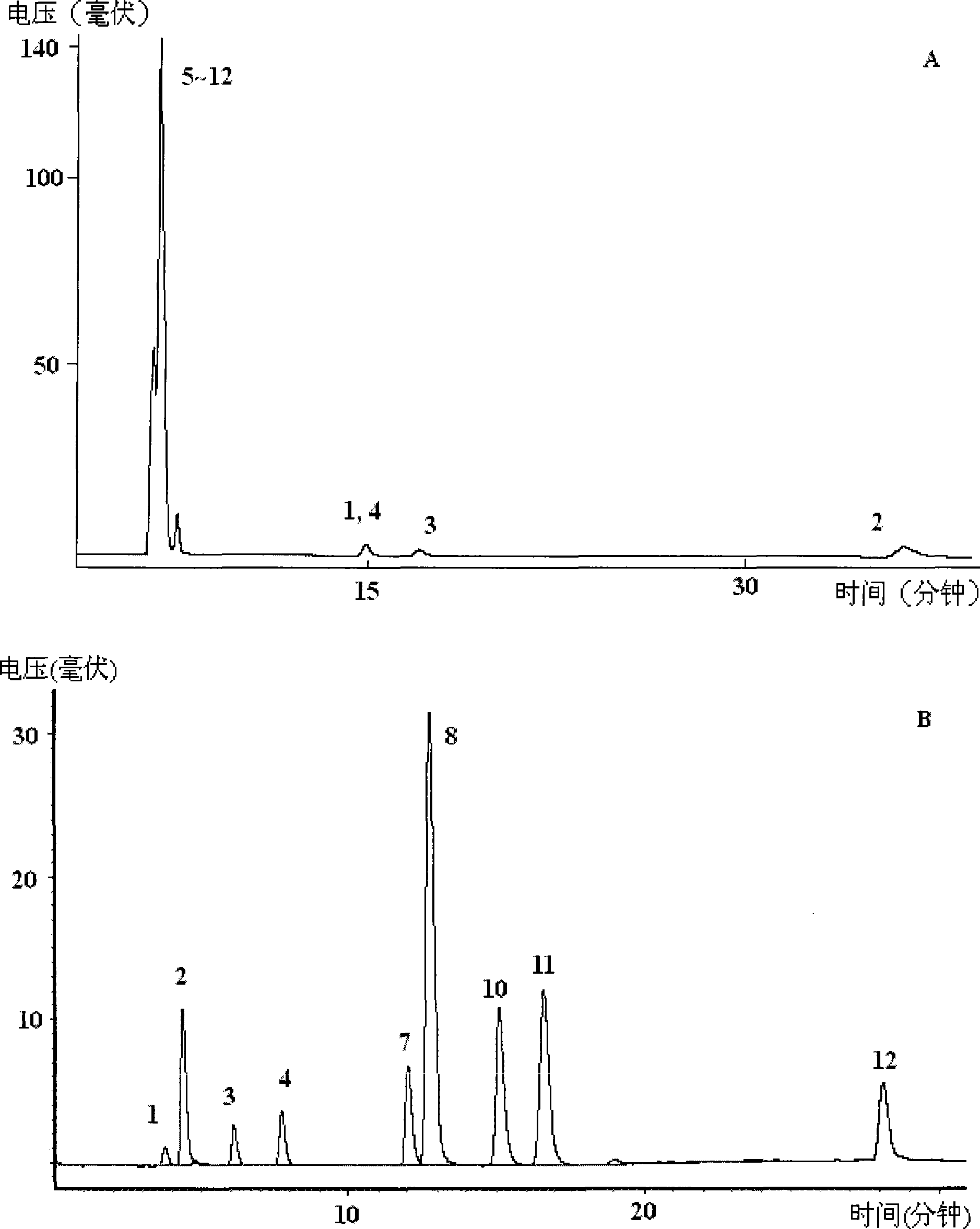

[0029] The experimental device and method are the same as in Example 1, and the ultrasonic extract of angelica n-hexane (90% n-hexane / 5% dichloromethane / 5% isopropanol) is analyzed. The first dimension normal phase chromatogram is shown in Figure 4 A, the analysis conditions are: chromatographic column, cyano column (150mm×2.0mm i.d., 5μm); mobile phase, 90% n-hexane / 5% dichloromethane / 5% n-propanol; flow rate 0.18mL / min; detection wavelength 254nm; injection volume 20μL. The chromatogram of reverse-phase direct injection is 4B, and the analysis conditions are: mobile phase, A, 5% methanol; B, methanol; gradient elution program, 0-40min, 40%B linearly increased to 100%B; 40-50min, 100% B; 50-55min, linearly decreasing to 40% B; flow rate 0.8mL / min; detection wavelength 254nm; injection volume 20μL. Cut the first-dimensional separation components into 10 parts, and enter the second-dimensional separation after passing through the interface respectively. See the spectrum Fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com