Preparation method of nanometer silica hollow microspheres

A nano-silicon dioxide, silicon dioxide technology, applied in the direction of silicon dioxide, silicon oxide, nanostructure manufacturing, etc., can solve the problem of difficult to effectively construct hollow microspheres, low yield of hollow microspheres, and chemical reactions of precursors Effectively control and other problems to achieve the effects of easy availability of emulsifiers, improved structural adjustability, and simple emulsifiers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

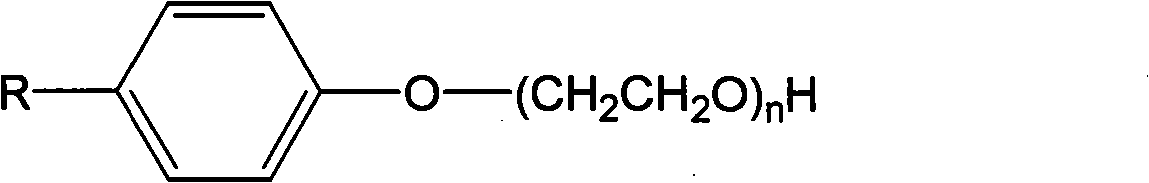

[0022] 1 part of nonylphenol ethoxylate ( n=4) into the Erlenmeyer flask containing 80 parts of cyclohexane, and under ultrasonic and mechanical stirring, 1 part of ammonia water (the concentration of ammonia water is 25%) was added dropwise to the Erlenmeyer flask to obtain a translucent emulsion. Then stop the ultrasound, under magnetic stirring, add 3 parts of ethyl orthosilicate, react at room temperature for 20 minutes, there is precipitation, continue to stir for 4 hours, filter, wash with ethanol, centrifuge, and dry at 60 ° C to obtain nanometer two Silica hollow microspheres. Observed under a transmission electron microscope, it is a hollow microsphere with an average particle diameter of about 500nm and a shell thickness of about 40nm.

Embodiment 2

[0024] 1 part of octylphenol ethoxylate ( n=6) into the Erlenmeyer flask containing 150 parts of cyclohexane, and under ultrasonic and mechanical stirring, 1 part of ammonia water (the concentration of ammonia water is 25%) was added dropwise to the Erlenmeyer flask to obtain a translucent emulsion. Then stop the ultrasound, add 10 parts of ethyl orthosilicate under magnetic stirring, react at room temperature for 20 minutes, there is precipitation, continue to stir for 4 hours, filter, wash with ethanol, centrifuge, and dry at 60°C to obtain nanometer two Silica hollow microspheres. Observed under a transmission electron microscope, it is a hollow microsphere with an average particle diameter of about 400nm and a shell thickness of about 80nm.

Embodiment 3

[0026] 1 part of nonylphenol ethoxylate ( n=4) add 100 parts of cyclohexane to the Erlenmeyer flask, and under ultrasonic and mechanical stirring, add 1 part of ammonia water (the concentration of ammonia water is 12.5%) dropwise to the Erlenmeyer flask to obtain translucent reverse phase lotion. Then stop the ultrasound, under magnetic stirring, add 3 parts of ethyl orthosilicate, react at room temperature for 30 minutes, there is precipitation, continue stirring for 8 hours, filter, wash with ethanol, centrifuge, and dry at 60 ° C to obtain nanometer two Silica hollow microspheres. Observed under a transmission electron microscope, it is a hollow microsphere with an average particle diameter of about 500nm and a shell thickness of about 30nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com