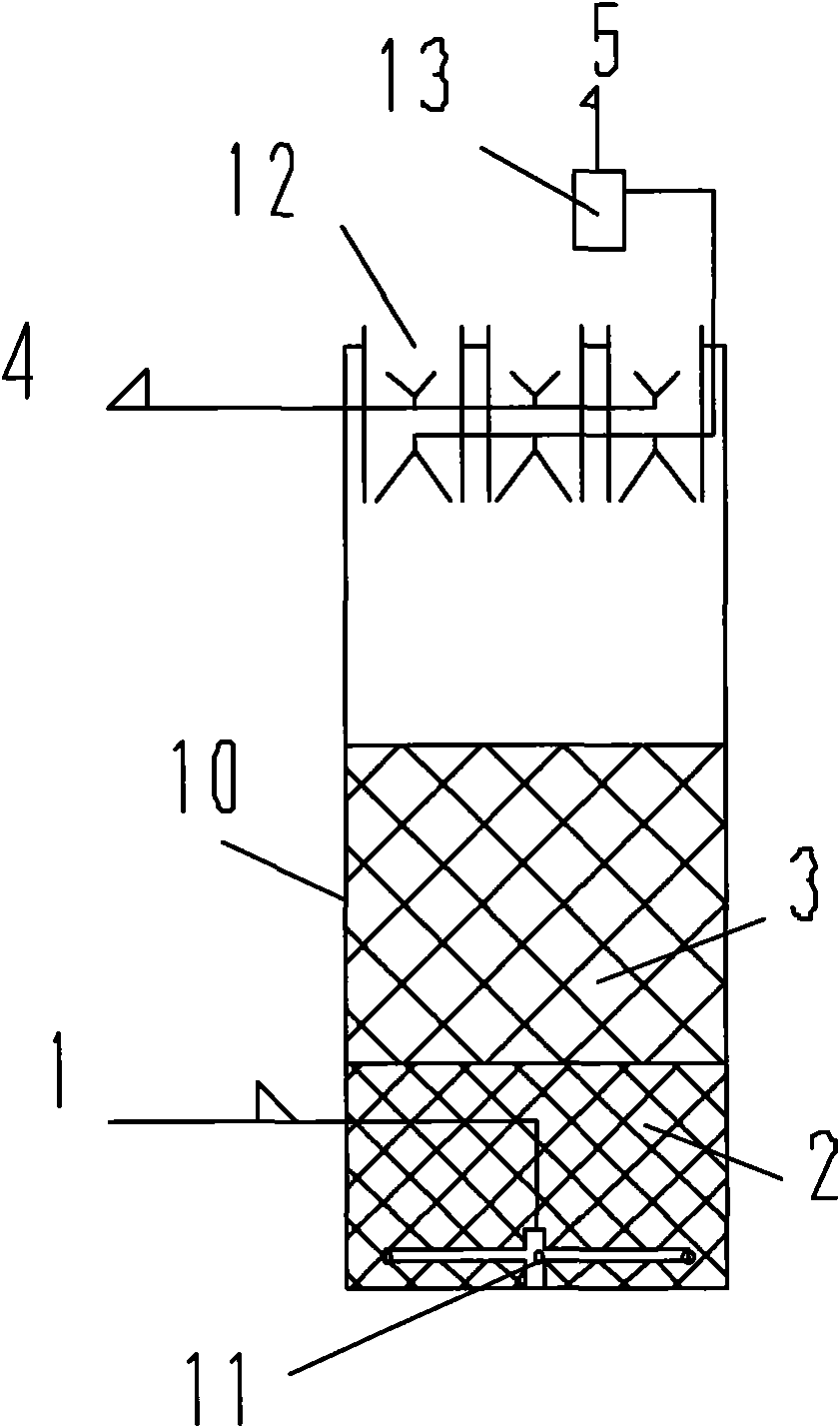

Organic waste water anaerobic treatment method

A technology for anaerobic treatment and organic wastewater, applied in anaerobic digestion treatment, waste fuel, etc., can solve the problems of reducing substrate concentration, increasing difficulty and cost, increasing treatment system cost and operating cost, etc., to achieve simple process and effective treatment stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Utilize the present invention to treat the waste water of brewery, the treated waste water volume is 8000-10000m3 / d, COD concentration is 1500-3500mg / L, adopts two anaerobic treatment devices with a diameter of 14 meters and a height of 18 meters. The remaining activated sludge produced by the treatment plant is anaerobically digested and dehydrated, and the water content of the sludge is about 70%. The sludge inoculation operation is started, and the COD concentration of the effluent is about 150-200mg / L, reaching a COD removal rate of more than 90%. processing effect.

Embodiment 2

[0044] Utilize the present invention to process the waste water of cassava raw material alcohol plant, the treated waste water volume is 1500-2000m3 / d, COD concentration is 28000-35000mg / L, adopts two anaerobic treatment devices with a diameter of 14 meters and a height of 15 meters, with a certain The remaining activated sludge produced by the urban sewage treatment plant is anaerobically digested and dehydrated, and the sludge inoculation with a water content of about 70% is started. The COD concentration of the effluent is about 1500mg / L, reaching a COD removal rate of more than 90%. processing effect.

Embodiment 3

[0046] Utilize the present invention to treat the waste water of the corn raw material fuel ethanol plant, the treated waste water volume is 5000-8000m3 / d, the COD concentration is 3000-6000mg / L, adopts six anaerobic treatment devices with a diameter of 15 meters and a height of 18 meters, with The residual activated sludge produced by a certain urban sewage treatment plant was anaerobically digested and dehydrated, and the sludge inoculation with a water content of about 70% was started. The COD concentration of the effluent was about 80-120mg / L, which reached the COD removal rate. More than 90% treatment effect.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com