Technique and industrial device for refining rice by supercritical polybasic fluid

An industrial device and supercritical technology, applied in the field of supercritical multi-fluid refined rice, can solve the problems of difficult implementation and promotion, large equipment investment, and long construction period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

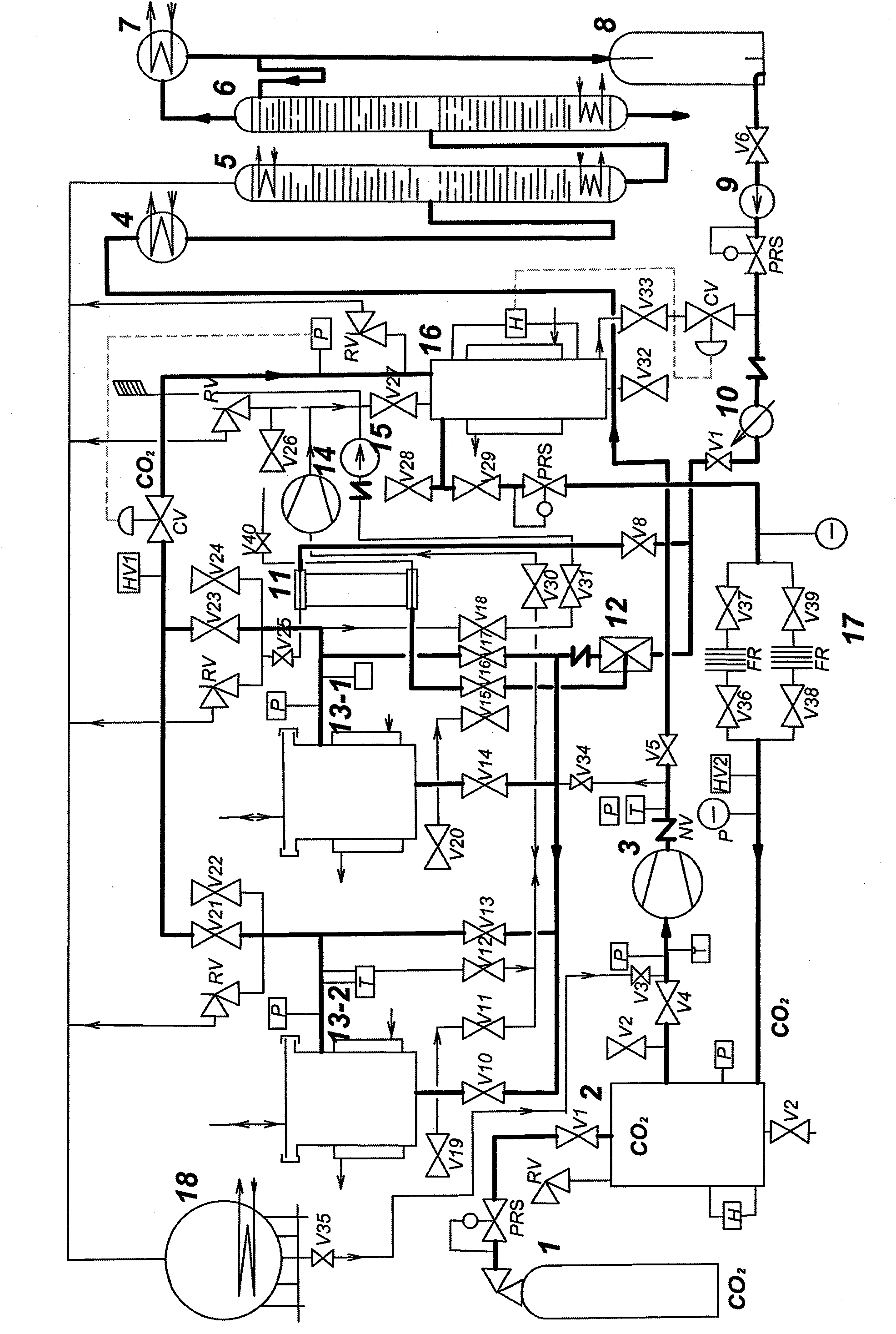

Image

Examples

specific Embodiment approach 1

[0023] Specific implementation scheme one: the paddy brown rice layer is pre-broken, the moisture content of the paddy brown rice is controlled at 15%, and it is packed into 10M 3 The material frames in the high-pressure extraction tank 13-1 and 13-2, paddy and brown rice are packed in layers in the material frame to reserve 15% of the micro-expansion space, after closing the tank cover, vacuum up to 10 through high vacuum pump 15 -2 mmHg, exhaust the air, and then pass the CO2 through the liquid carbon dioxide booster pump 9 and the heater 10 2 After replacing the air, pressurize to 12MPa and control the temperature at 32°C, stabilize the pressure for 30 minutes and quickly depressurize to 5.0MPa, cycle three times to oscillate to pre-break the wall, and then slowly release the pressure, so that the micro-expanded rice brown rice is slowly closed, pre-treated by supercritical fluid oscillation. Broken wall treatment kills harmful bacteria, mold and insect eggs in paddy brown ...

specific Embodiment approach 2

[0024] Specific embodiment two: the preparation of sweet-scented osmanthus, rose, jasmine fragrant rice, according to specific embodiment one, first after paddy brown rice layer is pre-broken, the pressure is stabilized at 12MPa and the temperature is controlled at 32°C. In the multi-component solvent tank 11, add The osmanthus after freeze-drying, rose, jasmine use supercritical carbon dioxide fluid to extract essential oil and natural food-grade deodorant, feed supercritical carbon dioxide fluid, fresh flower essential oil and natural food-grade deodorant in multi-component solvent tank 11 The agent slowly and evenly passes through the high-efficiency multi-component solvent mixer 12 to form a supercritical multi-component fluid. The pre-broken brown rice in the high-pressure extraction tanks 13-1 and 13-2 is used to add aroma to the supercritical multi-component fluid. Pressurize from 12MPa to 22MPa, add aroma for 30 minutes, stabilize the pressure for 30 minutes, and then r...

specific Embodiment approach 3

[0025] Specific embodiment three: the preparation of purple sweet potato red pigment, capsanthin, lycopene, sophora japonica yellow pigment rice, according to specific embodiment one, first after pre-breaking the paddy brown rice layer, stabilize the pressure at 12MPa and control the temperature at 32 ℃, in the multi-component solvent tank 11, add purple sweet potato red pigment, capsanthin, lycopene, and Sophora japonica yellow pigment prepared by supercritical multi-component fluid, and pass into supercritical carbon dioxide fluid in the multi-component solvent tank 11, These natural pigments pass through the high-efficiency multi-component solvent mixer 12 slowly and evenly to form a supercritical multi-component fluid, and color the supercritical multi-component fluid to the pre-broken brown rice in the high-pressure extraction tanks 13-1 and 13-2. The coloring pressure is from 12MPa is pressurized to 22MPa, the coloring time is 30 minutes, the pressure stabilization time i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com