Film silicon photovoltaic device and manufacturing method, back electrode and photovoltaic component thereof

A technology of photovoltaic devices and thin-film silicon, which is applied in photovoltaic power generation, semiconductor devices, and final product manufacturing. Achieve the effects of avoiding TCO deposition process, suppressing shunt and instability, and good photoelectric conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings, in which like reference numerals denote like elements throughout. It should be understood that the embodiments described herein are illustrative only and should not be construed as limiting the scope of the present invention.

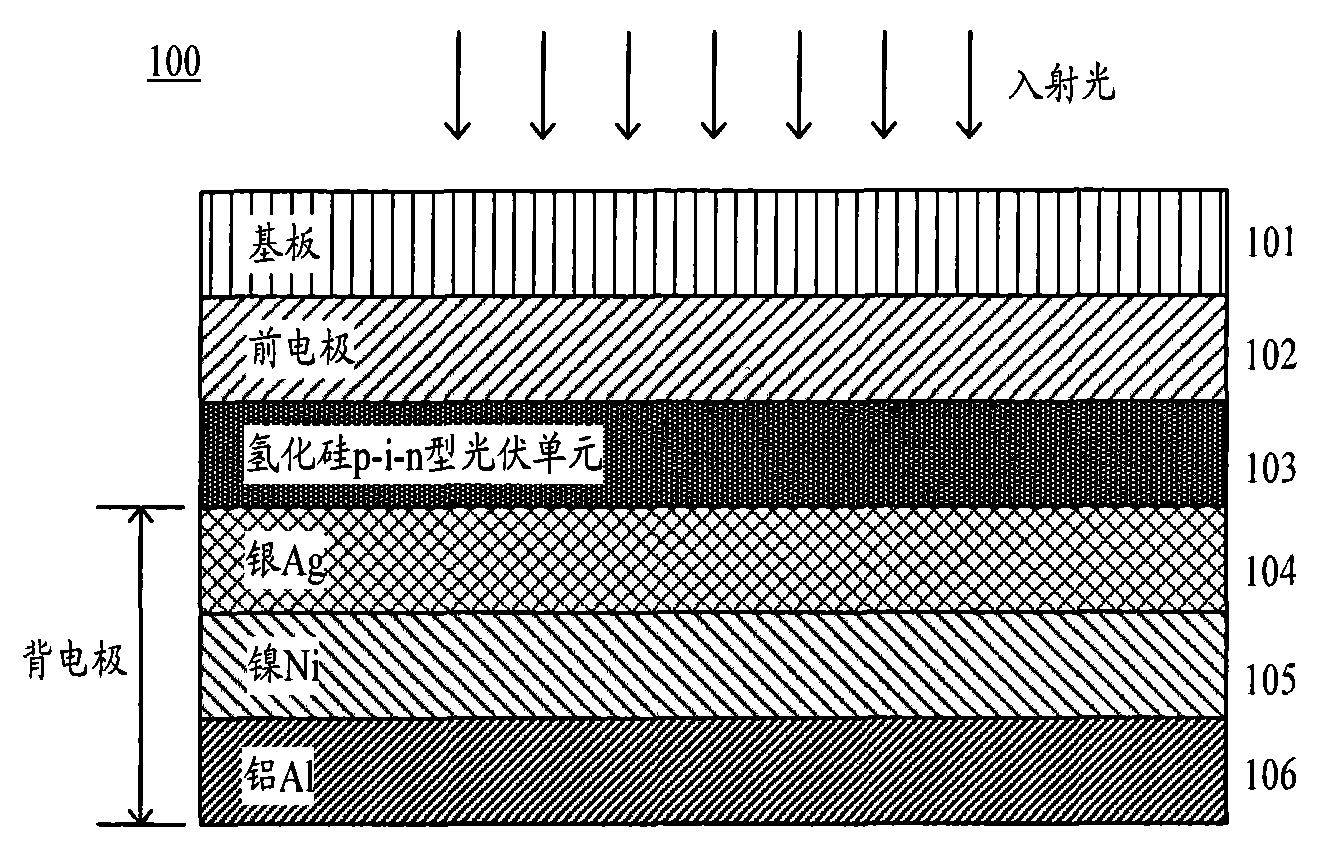

[0036] The proposal of the back electrode according to the invention is based on the following important facts. Silver and nickel are matching metal materials, and the optical and / or conductive properties of the back electrode will not be significantly affected by the diffusion of silver atoms and nickel atoms between the silver film and the nickel film. In contrast, in conventional back electrodes, severe interdiffusion occurs between silver and aluminum (Ag / Al) thin films, resulting in poor optoelectronic performance of the back electrodes. In addition, nickel has good electrical conductivity and chemical stability, as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com