Silica-based germanium electrical injection laser and production method thereof

A laser and silicon-based technology, applied in the direction of lasers, laser components, semiconductor lasers, etc., can solve problems such as the lack of light emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

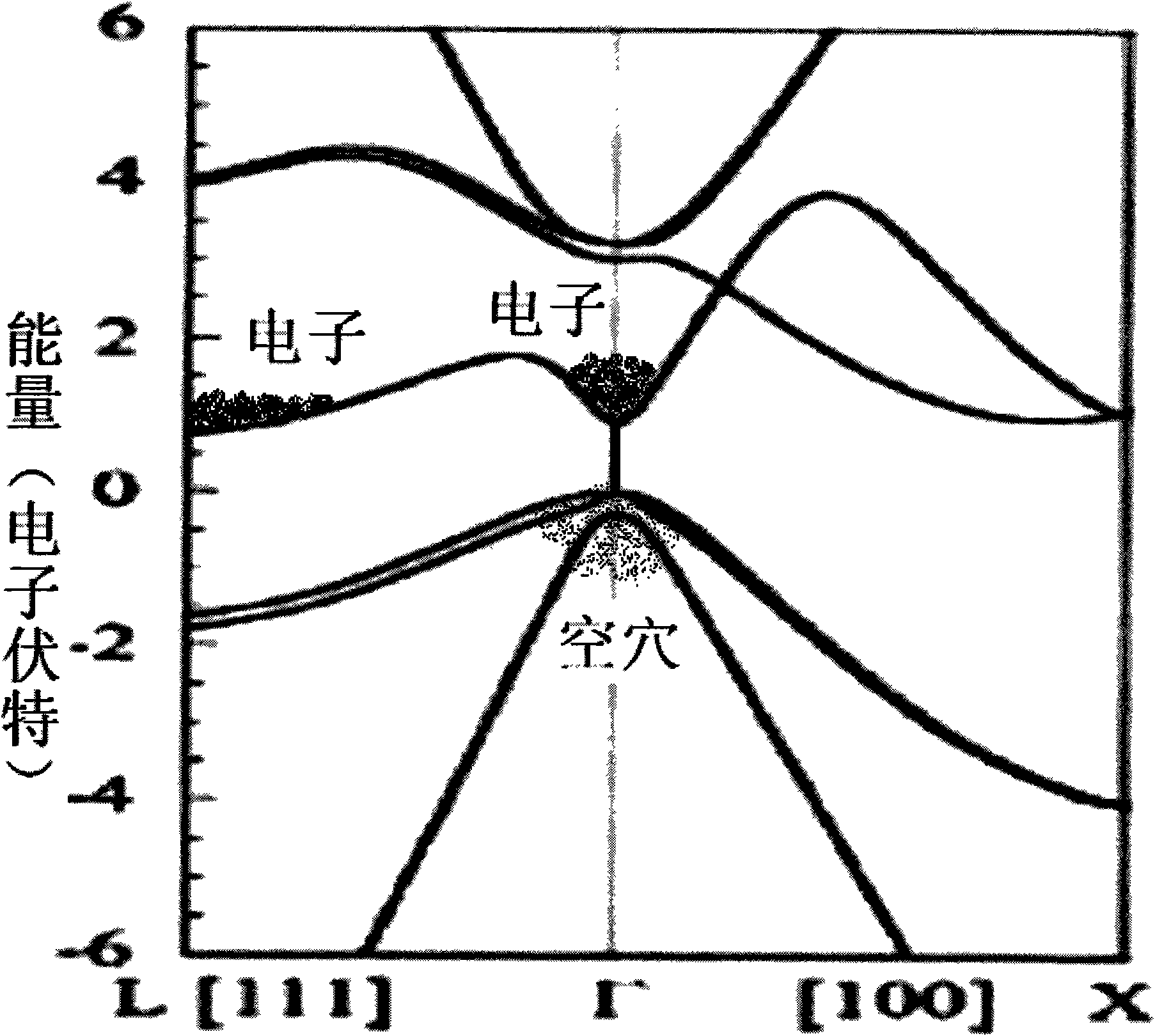

[0043] from figure 1 It can be seen from the energy band structure diagram of germanium that germanium is an indirect bandgap semiconductor material, the lowest conduction band valley is located at the L point ( direction) of the Brillouin zone, and the second lowest conduction band valley is located at the Brillouin zone center Г point ( k=0), there is the second lowest X point in the direction. The energy gap difference between the Г conduction band valley and the L conduction band valley is about 0.136eV (room temperature), and the X conduction band valley is about 0.18eV higher than the Г conduction band valley (room temperature). According to the Boltzmann distribution principle, at higher temperatures, in addition to the main electron concentration in the lowest L conduction band valley, there are also a relatively large number of electrons (not more than 5%) in the Γ conduction band valley.

[0044] However, even so, under normal circumstances, germanium-based materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Doping concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com