Dropping-coating preparation method for photoelectric-conversion composite coating films based on C60/tetra-n-octylammonium bromide

A technology of tetraoctylammonium bromide and composite coating, which is applied in the field of drop coating preparation, can solve problems such as easy aggregation, low photoelectric conversion efficiency, and unstable electrochemical properties of the film, and achieve high photoelectric conversion performance and voltage response The effects of sensitivity, high-efficiency photoelectric conversion capability, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

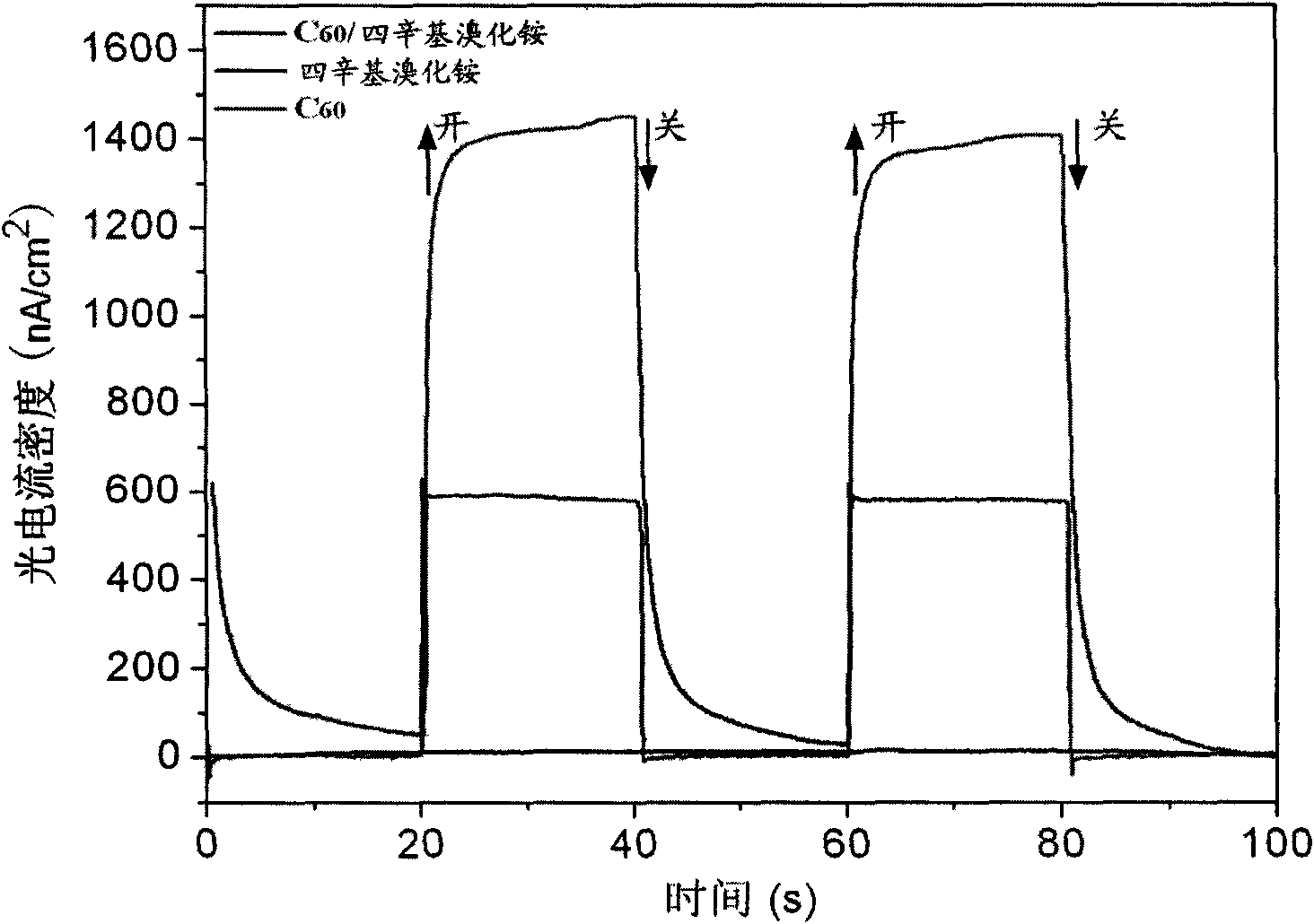

[0025] Example 1: C 60 / Tetraoctylammonium bromide composite coating film preparation by drop coating and photoelectric conversion performance test

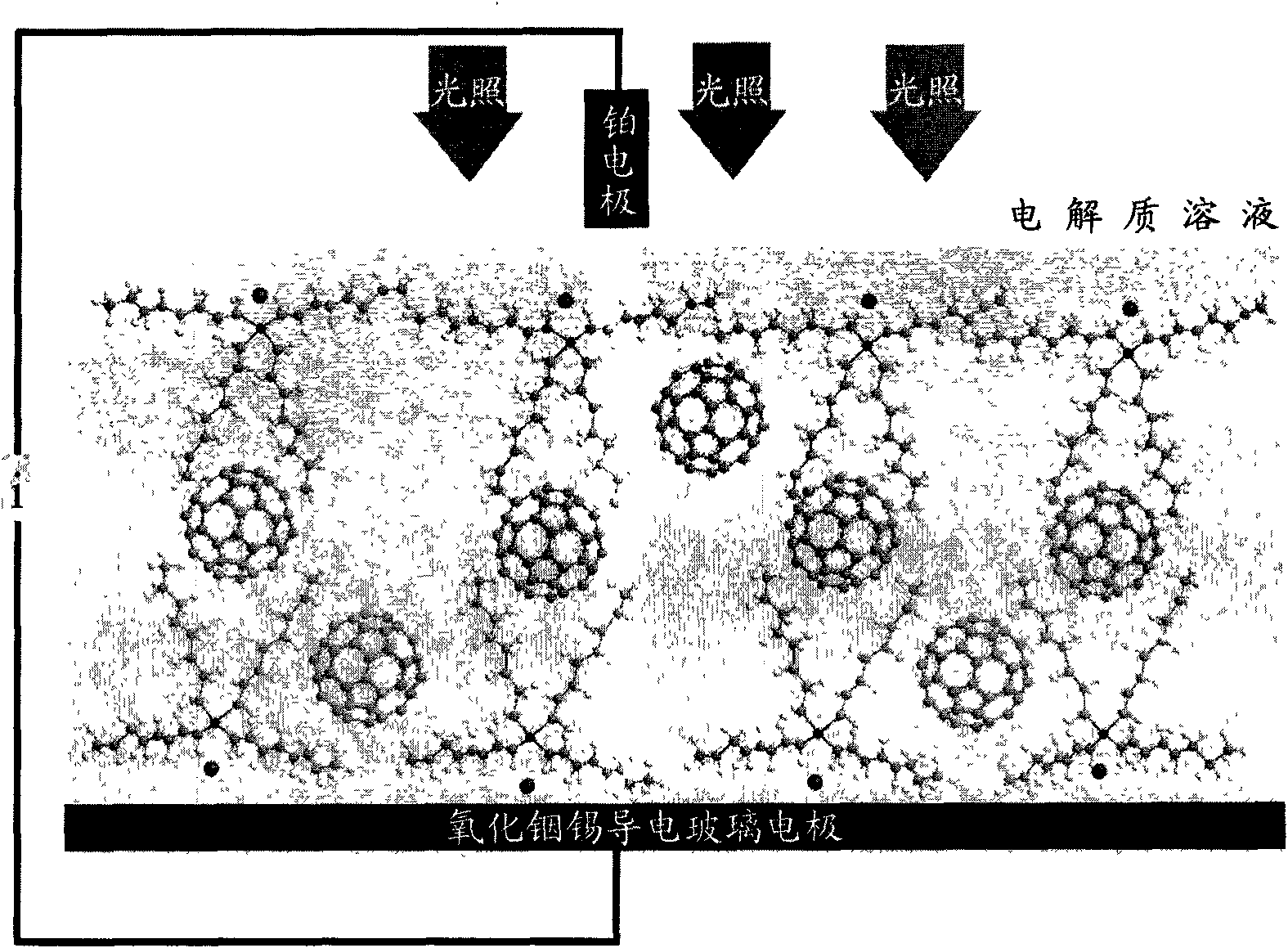

[0026] First, clean the indium tin oxide conductive glass electrode with clear water, then ultrasonically clean it with acetone and ethanol in sequence, and then blow it dry with nitrogen flow. 1.0mM and 10mM C 60 Mix with tetraoctylammonium bromide in toluene, dissolve in ultrasonic, and get purple C 60 and tetraoctylammonium bromide in toluene. With a 10 µl pipette, transfer the C 60 and tetraoctylammonium bromide toluene solution evenly drop-coated on the surface of indium tin oxide conductive glass electrode, drop-coated three times, 10 μl each time. Dispensing area is 1.2cm 2 , the drop-coated film layer was left to dry in air at room temperature, and the coating surface was further purged with high-purity nitrogen flow before the photoelectrochemical experiment.

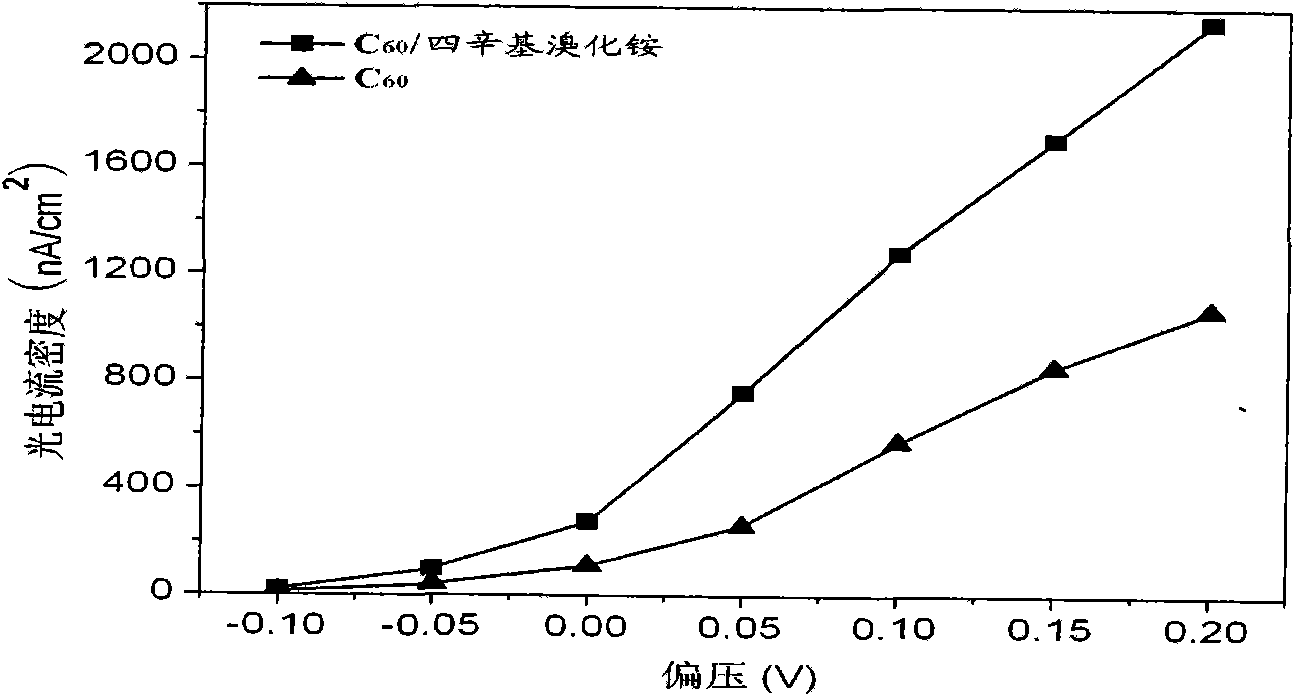

[0027] Use fluorescence cuvette as photoelectrochemic...

Embodiment 2

[0029] The concentrations of 1.0mM and 5mM C 60 Mix with tetraoctyl ammonium bromide in toluene, all the other operations are as embodiment 1, and coating area is 1.0cm 2 , the resulting photocurrent is 645nA / cm 2 . The result is as Figure 4 Show.

Embodiment 3

[0031] The concentrations of 1.0mM and 15mM C 60 Mix in toluene with tetraoctyl ammonium bromide, all the other operations are as embodiment 1, and coating area is 0.8cm 2 , the resulting photocurrent is 855nA / cm 2 . The result is as Figure 5 Show.

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com