Stable aluminate-based phosphor powder, preparing method and application thereof

A technology of phosphor and aluminate, applied in the field of phosphor and preparation, can solve the problem of chemical stability of blue phosphor without barium magnesium aluminate base, and achieves suitable for large-scale industrial production, high luminous efficiency and stability , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] According to the chemical formula Eu x Ba 1-x MgAl 10-y Si y o 17-y N y , take x=0.12, y=0.03, weigh BaCO 3 0.88mol, Al 2 o 3 4.97mol, MgO 1.00mol, AlN 0.03mol, SiO 2 0.03mol, Eu 2 o 3 0.06mol, put these raw materials together into a ball mill tank, add 50 ml of absolute ethanol at the same time, ball mill on a planetary ball mill for 10 hours, mix well, dry, and pass the obtained powder through a 500 μm sieve to make it fall freely into boron nitride In the crucible, the stacking relative density is about 30%, then cover the non-sealed top cover, put it into a vacuum carbon tube furnace, and then firstly evacuate it through a diffusion pump, and heat it from room temperature to 800 °C at a speed of 500 °C per hour, 800 ℃ by introducing nitrogen with a purity of 99.99%, then raising the temperature to 1500 ℃ at a rate of 500 ℃ per hour, and keeping it warm for 2 hours, then turn off the power, and cool naturally to room temperature before taking it out.

...

Embodiment 2

[0056] According to the chemical formula Eu x Ba 1-x MgAl 10-y Si y o 17-y N y , take x=0.10, y=0.50, weigh BaCO 3 0.90mol, Al(OH) 3 9.00mol, MgO 1.00mol, AlN 0.50mol, SiO 2 0.50mol, Eu 2 o 3 0.05mol, put these raw materials together into a ball mill jar, add 50ml of absolute ethanol at the same time, ball mill on a planetary ball mill for 10 hours, mix well, dry, and pass the obtained powder through a 500μm sieve to make it fall freely into an alumina crucible Inside, the stacked relative density is about 30%, then cover the non-sealed top cover, put it into the corundum tube furnace, firstly evacuate it through the diffusion pump, and then pass the flowing N with a purity of 99.99% 2 / NH 3 (Its volume ratio is 5: 1) the mixed gas is heated up to 1400°C at a heating rate of 3°C / min, and after 10 hours of heat preservation, it is cooled naturally at a cooling rate of 5°C / min to 800°C. The burned product is crushed, then ball-milled to form a powder slurry, washe...

Embodiment 3

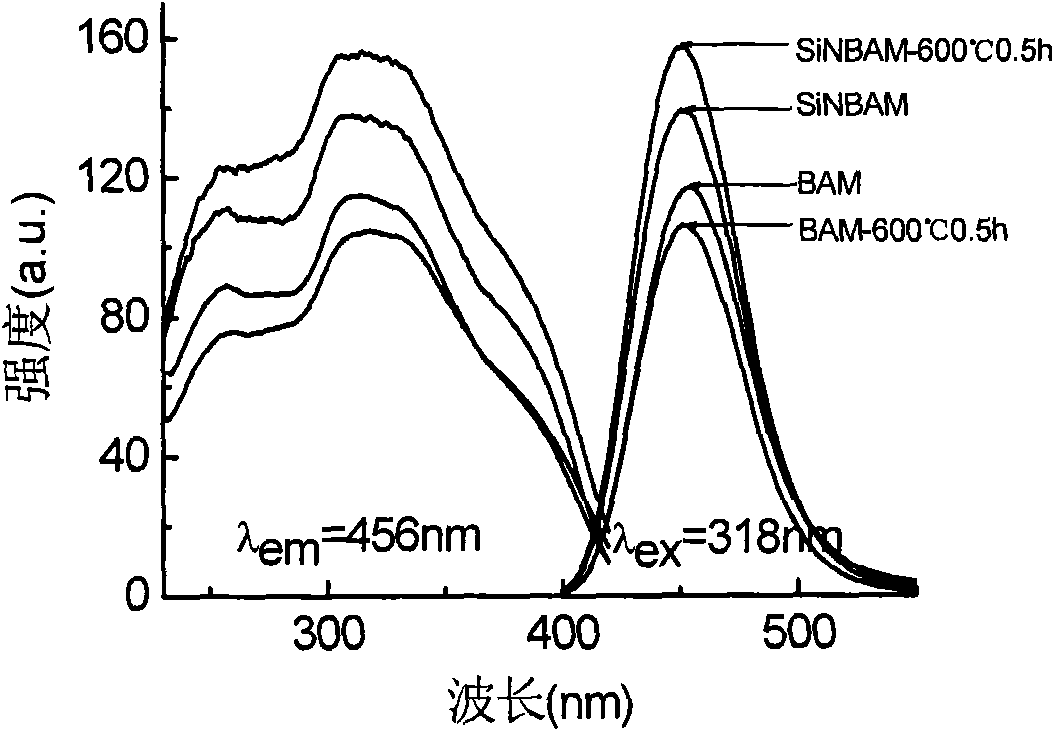

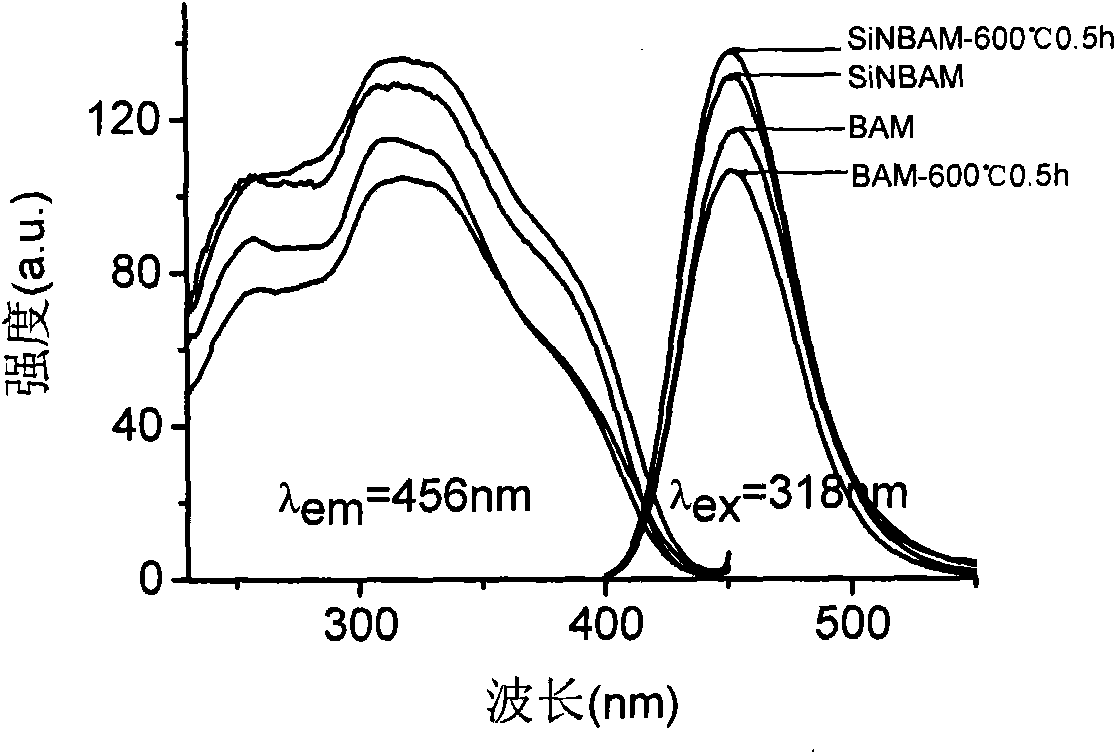

[0060] According to the chemical formula Eu x f 1 1-x f 2 al 10-y Si y o 17-y N y , take F1 = Ba and Ca, F 2 =Mg, x=0.12, y=1.50, weigh BaCO 3 0.86mol, CaCO 3 0.02mol, Al 2 o 3 4.25mol, MgCO 3 1.00mol, Si 3 N 4 0.375mol, SiO 2 0.375mol, Eu 2 o 3 0.06mol, other conditions are the same as in Example 2, and the temperature is raised to 1450° C. at a heating rate of 2° C. / min. After 6 hours of heat preservation, it is naturally cooled to 800° C. at a cooling rate of 5° C. / min. The burning product is crushed, then ball milled to form a powder slurry, washed with deionized water until neutral, dehydrated, dried, and sieved to obtain a highly stable barium magnesium aluminate-based blue phosphor. According to the same method as in Example 1, compare the heat treatment stability of SiNBAM and BAM provided in this experiment. Compared with the corresponding pure BAM, its luminous efficiency before and after heat treatment was increased by 6% and 19%, respectivel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com