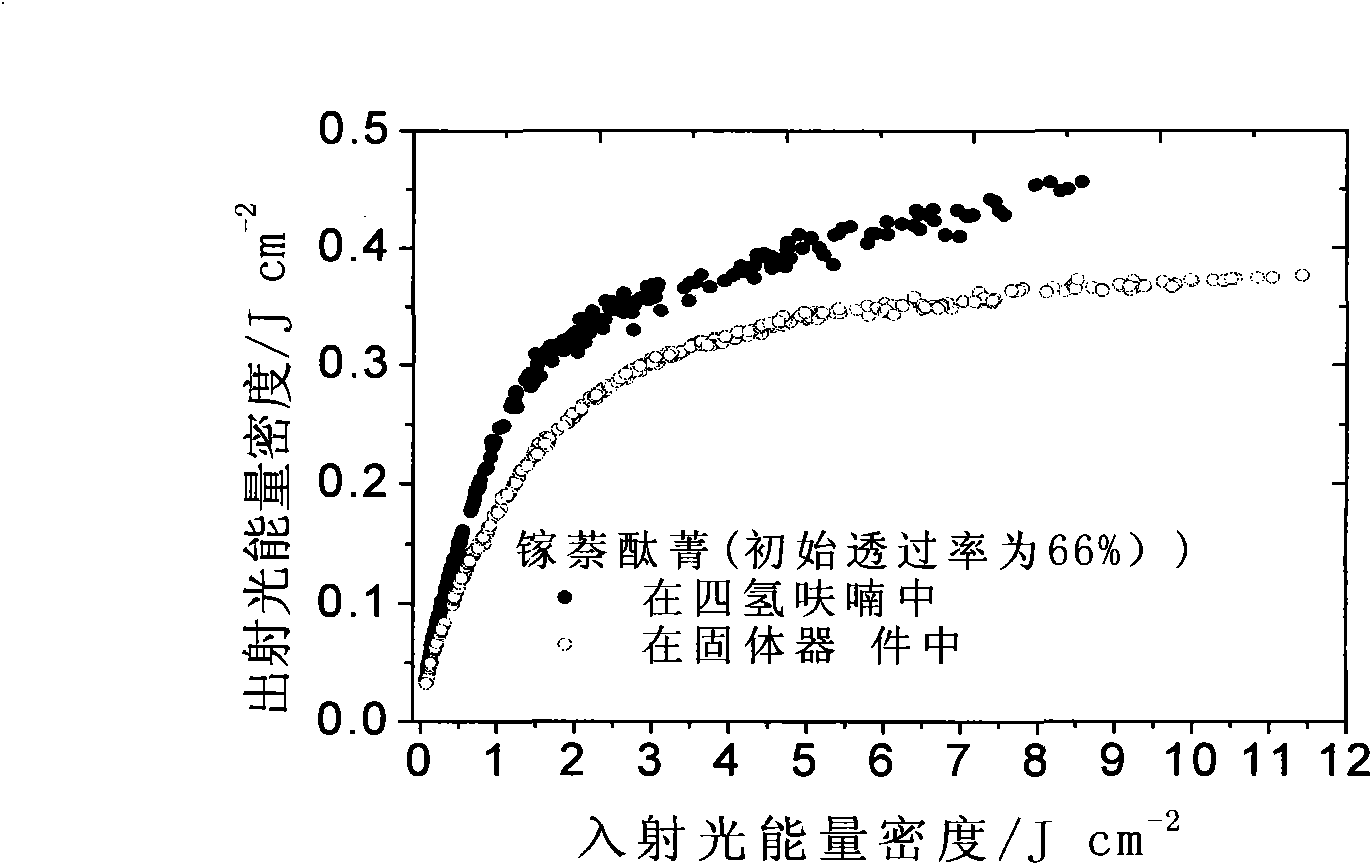

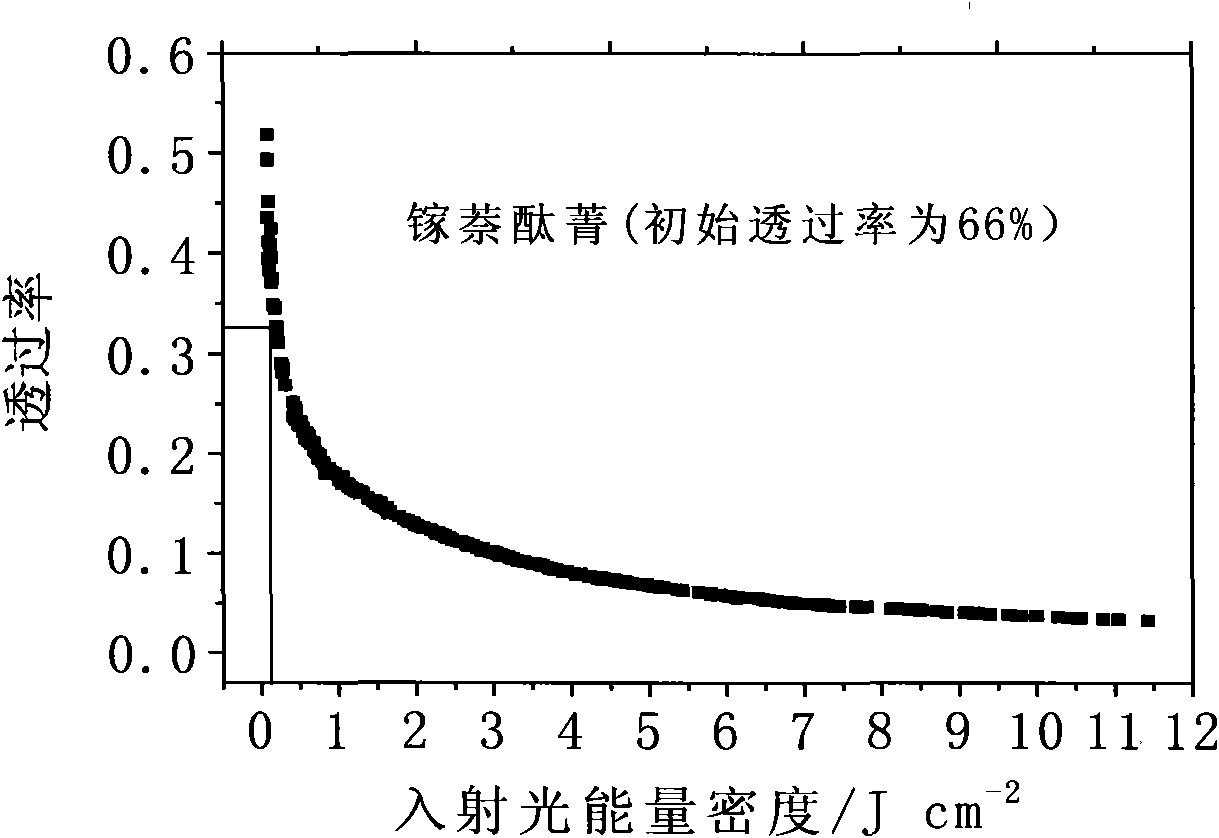

Solid naphthalocyanine device with optical limiting properties

A naphthalocyanine, optical limiting technology, applied in the fields of instruments, optics, nonlinear optics, etc., can solve the problems of fragile anti-laser ability, etc., and achieve good anti-laser ability, good anti-laser ability, and excellent optical limiting. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

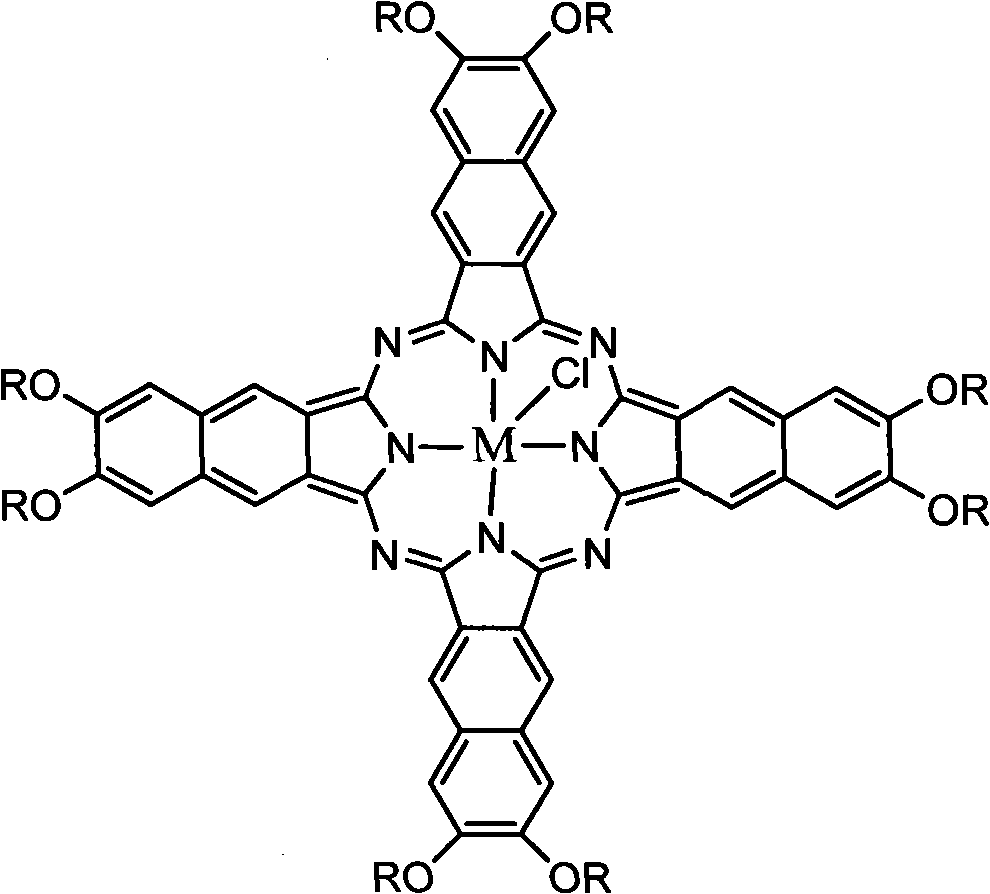

Embodiment 1

[0026] 4.74g (10mmol) of 6,7-di-tert-butylphenoxy-2,3-naphthalenedicarbonitrile and 10ml of analytically pure amyl alcohol were added to a 50ml there-necked flask, heated to 60°C in an oil bath, and 1ml of 1 , 8-diazacyclo[5,4,0]undecene-7 (DBU) was used as a catalyst, and the temperature was slowly raised to 110 °C for 2 hours, and then 0.45 g of anhydrous GaCl was added. 3 And the temperature was raised to 140 ℃, after heating and refluxing for 36 hours, the heating was stopped. When the solution was cooled to room temperature, 50 ml of a mixed solution of methanol and water with a volume ratio of 1:1 was added. The product was passed through a silica gel column with a mixed solvent of dichloromethane and tetrahydrofuran (THF) in a volume ratio of 20:1 as a developing solvent to obtain a gallium naphthalocyanine compound with a yield of 62%. Ultraviolet-visible (THF) λmax: 799, 340 nm; mass spectrum (MALDI-TOF): 2001.1 (M + ), 1966.2 (M + -Cl), 1817.1 (M + -Cl-OR), 1669.0...

Embodiment 2

[0028] 4.74g (10mmol) of 6,7-di-tert-butylphenoxy-2,3-naphthalenedicarbonitrile and 10ml of analytically pure amyl alcohol were added to the there-necked flask of 50ml, and after the oil bath was heated to 60°C, 1ml of DBU was added. As a catalyst, the temperature was slowly raised to 110 °C and heated for 2 hours, and then 0.55 g of anhydrous InCl was added. 3 And the temperature was raised to 140 ℃, after heating and refluxing for 36 hours, the heating was stopped. When the solution was cooled to room temperature, 50 ml of a mixed solution of methanol and water with a volume ratio of 1:1 was added, and a yellow-green group was obtained by filtering and washing. The product was passed through a silica gel column with a mixed solvent of dichloromethane and tetrahydrofuran having a volume ratio of 20:1 as a developing solvent to obtain an indium naphthalocyanine compound with a yield of 58%. Ultraviolet-visible (THF) λmax: 802, 339 nm; mass spectrum (MALDI-TOF): 2046.2 (M + ),...

Embodiment 3

[0030] 4.74g (10mmol) of 6,7-di-tert-butylphenoxy-2,3-naphthalenedicarbonitrile, 0.46g anhydrous SnCl 2 , 10ml of 1-chloronaphthalene was added to the three-necked flask of 50ml, after the oil bath was heated to 190 ℃, the reaction was stopped after 4 hours, when the solution was cooled to room temperature, 50ml of n-hexane was added, and the yellow-green was obtained after filtration and washing. Group product, using a mixed solvent of dichloromethane and tetrahydrofuran with a volume ratio of 20:1 as a developing agent to pass through a silica gel column to obtain a tin naphthalocyanine compound with a yield of 55%. Ultraviolet-visible (THF) λmax: 821, 346 nm; mass spectrum (MALDI-TOF): 2085.6 (M +), 2014.5 (M + -2Cl), 1485.8 (M + -40R); 1 H-NMR (CDCl 3 , 400Hz): 9.54(s, 8H), 8.55(s, 8H), 7.50-7.55(d, 16H), 7.27-7.33(d, 16H), 1.44(s, 72H); elemental analysis (%): measured Found C 73.64, H 5.75, N 5.37; found C 73.44, H 5.04, N 5.83.

[0031] 2. Preparation of Solid Sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com