Method of low-temperature catalytic dechlorination of chlorophenol

A technology of chlorinated phenol and low-temperature catalysis, which is applied in the direction of chemical instruments and methods, preparation of organic compounds, physical/chemical process catalysts, etc., can solve the problems of low reaction efficiency, achieve the effect of improving catalytic performance and good industrialization prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Grind coconut shell activated carbon and sieve to obtain activated carbon powder of 300-400 mesh. Add a certain amount of activated carbon to 10wt.% nitric acid, stir in 80°C water bath for 2 hours, then filter and wash with distilled water until neutral. Water steam is then processed, dried, and set aside. Palladium chloride is dissolved in 10wt.% hydrochloric acid aqueous solution, dubbed 1.7 * 10 -2 mol / L palladium chloride solution. Add 10g of activated carbon treated with nitric acid into 165ml of prepared palladium chloride aqueous solution, immerse for 2 hours, then add 8ml of formaldehyde for reduction, and at the same time add saturated sodium bicarbonate solution dropwise, control the pH value to about 9, and react until the pH value is low. Change. Filter and dry to obtain a Pd / C catalyst with a Pd content of 5 wt.%.

[0022] The reaction process is that 0.648g (5mmol) p-chlorophenol, 0.511g (5mmol) triethylamine, 0.10g 5wt.% Pd / C catalyst, and 50ml methan...

Embodiment 2

[0024] Palladium chloride is dissolved in 10wt.% hydrochloric acid aqueous solution, dubbed 1.7 * 10 -2 mol / L palladium chloride solution, get 85ml, add 10g coconut shell activated carbon (300 mesh) processed by the method of Example 1 and soak for 2h, then add 8ml formaldehyde for reduction, drip saturated sodium bicarbonate solution simultaneously, control the pH value is about 9, react until the pH value remains unchanged, filter and dry to obtain a Pd / C catalyst with a Pd content of 2.5wt.%.

[0025] The reaction process is that 0.648g of p-chlorophenol, 0.20g of 2.5wt.% Pd / C catalyst, and 50ml of methanol solution are added to a 100ml three-necked flask with a mechanical stirring device, and the temperature is controlled at -15 to -10°C with an ice-salt solution bath. After the replacement of hydrogen in the kettle for 6 times, under the condition that the hydrogen pressure is atmospheric pressure, turn on the mechanical agitation, and the rotating speed is 500rpm. During...

Embodiment 3

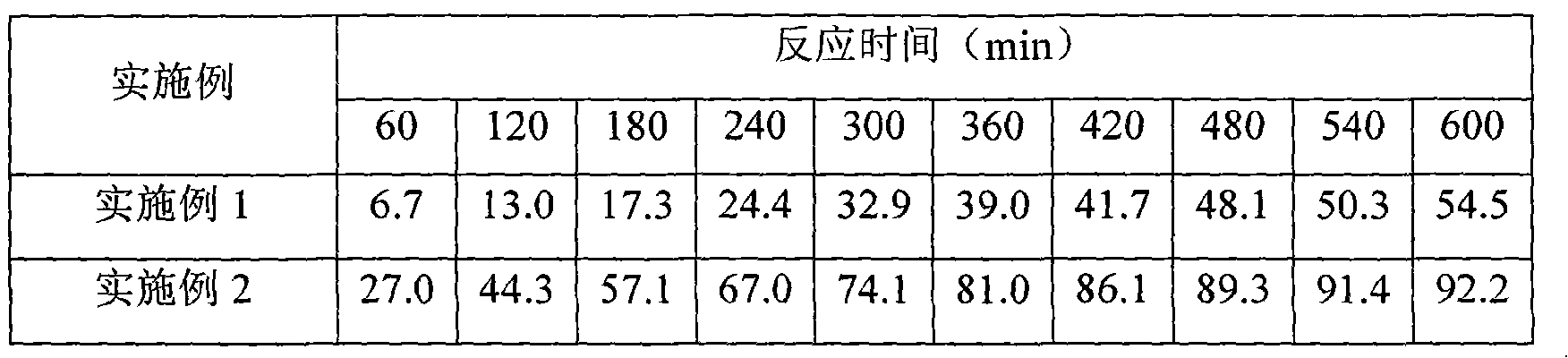

[0027] Get 0.10g of 5wt.%Pd / C catalyst prepared in Example 1, 0.643g of o-chlorophenol, and 0.511g of triethylamine and put them into 50ml of methanol solution to make a suspension, add it to a 100ml three-port Flask, other reaction conditions are identical with embodiment 1, by certain time interval, continuous sampling, learn with gas chromatographic analysis, reaction product is phenol, does not detect other compounds to generate. The results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com