Small-particle yellow rare-earth fluorescent powder and preparation method and purpose of visualizing latent fingerprint thereof

A technology of rare earth phosphors and small particles, applied in chemical instruments and methods, applications, luminescent materials, etc., can solve problems that have not yet appeared, and achieve the effects of eliminating object background interference, simple fingerprint display technology, and high fluorescence intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

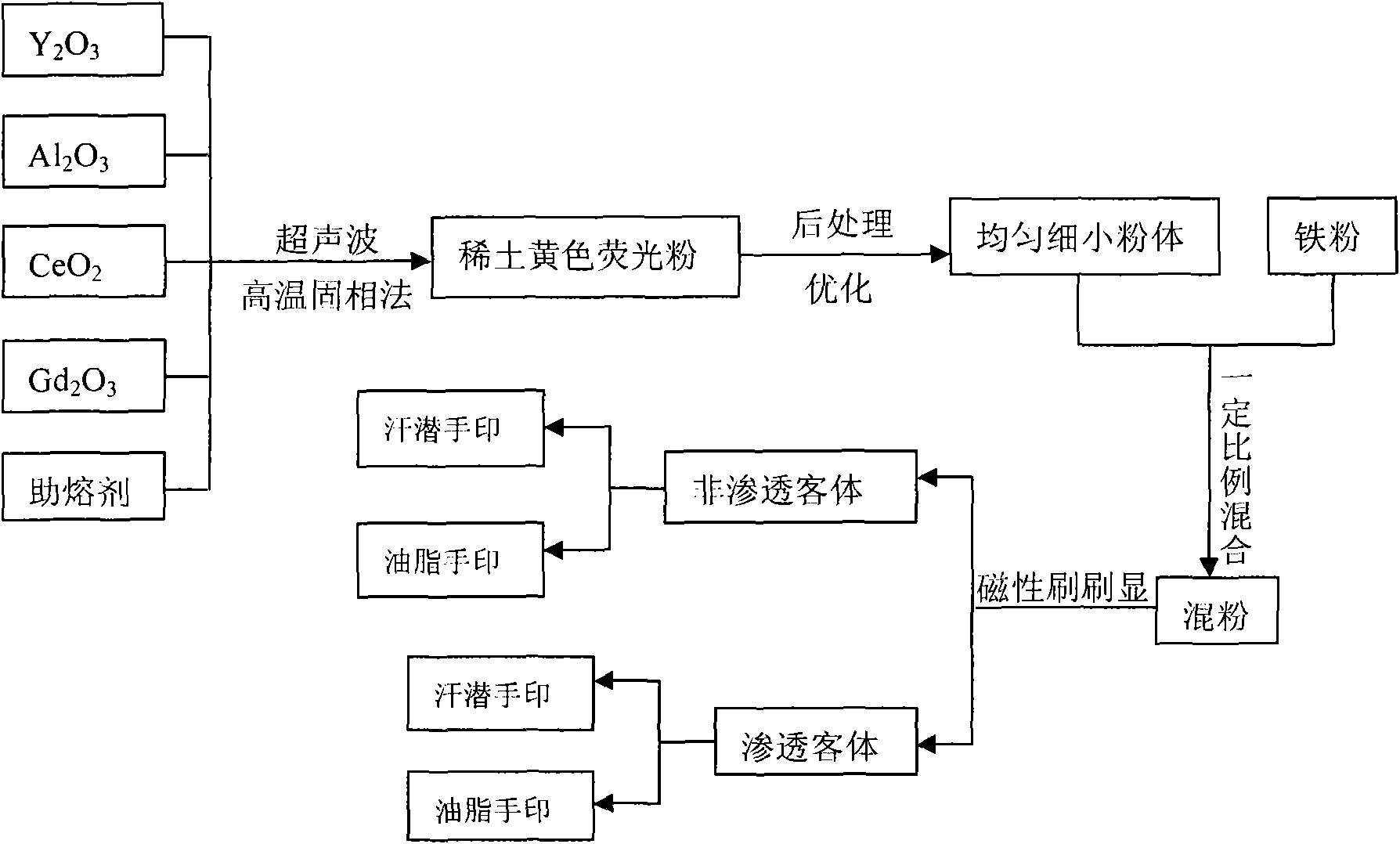

Method used

Image

Examples

Embodiment 1

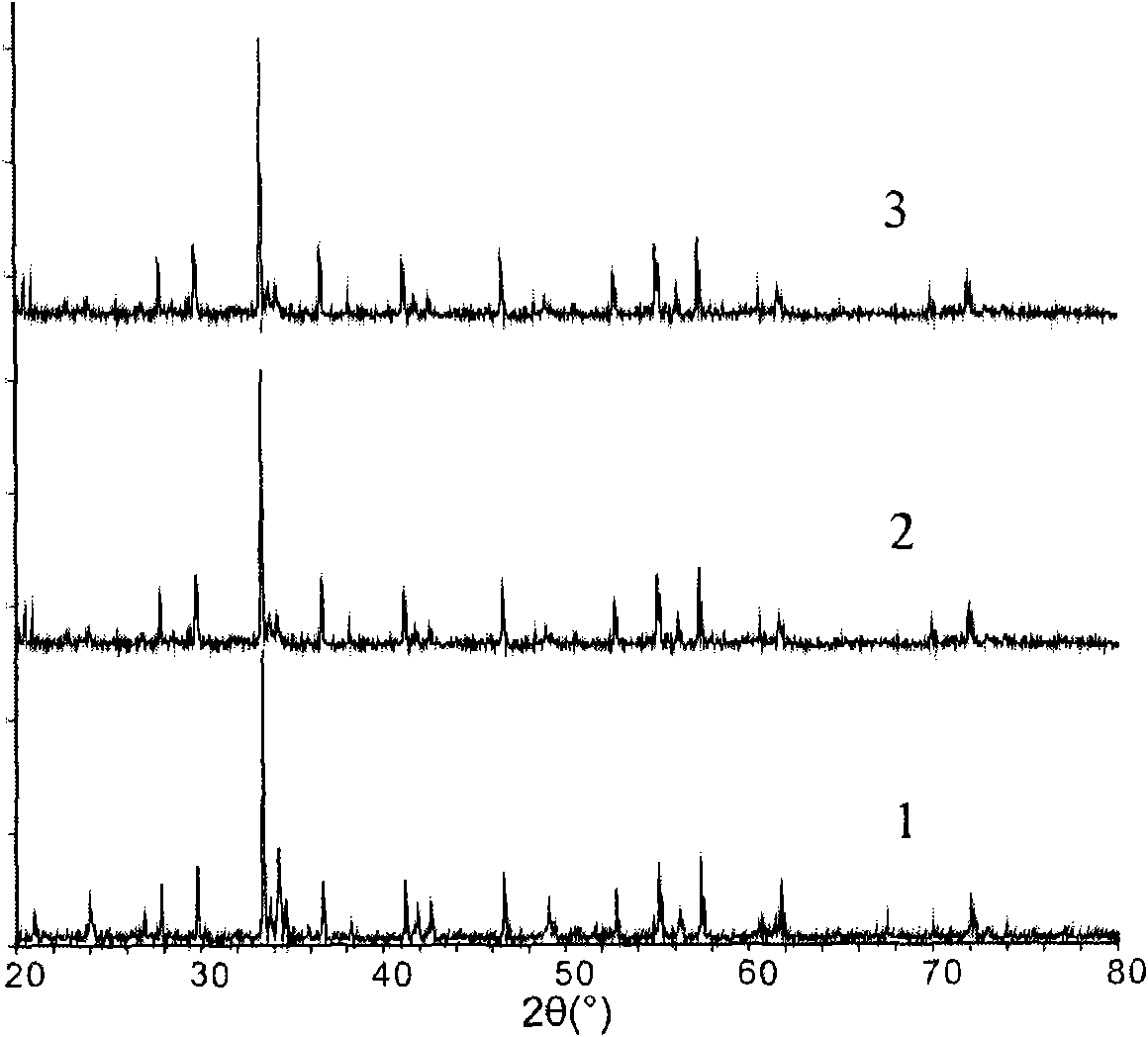

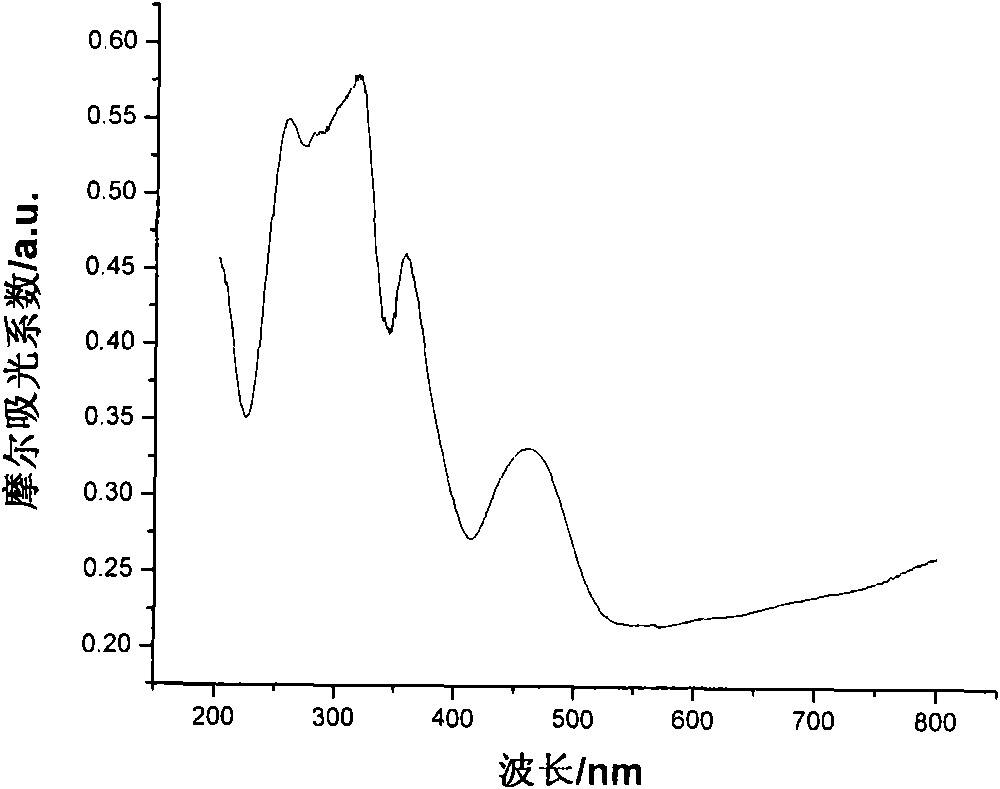

[0036] (1) Press Y 3-x-y Ce x Gd y Al 5 o 12 The stoichiometric ratio of the metal elements in the medium (where x=0.2, y=0.2), that is, according to the ratio of the amount of the substance of Y:Ce:Gd:Al is 2.6:0.2:0.2:5, weigh Al 2 o 3 , Y 2 o 3 , CeO 2 and Gd 2 o 3 , and then weigh the equivalent Al 2 o 3 , Y 2 o 3 , CeO 2 and Gd 2 o 3 Total weight 2% BaF 2 As a flux, put the weighed reagent in an agate mortar and grind it for 20-60 minutes to make it evenly ground, mix it evenly, and put it into a corundum crucible;

[0037] (2) Put the corundum crucible with reagents into a high-temperature reduction furnace, sinter at 1400°C for 4 hours in a hydrogen reduction atmosphere (or reduction with carbon powder), and then take out the sample after cooling to room temperature with the furnace;

[0038] (3) Grinding the powder obtained by sintering and passing through a 300-mesh sieve to obtain the primary powder;

[0039] (4) Soak the primary powder in nitric a...

Embodiment 2

[0046] (1) Press Y 3-x-y Ce x Gd y Al 5 o 12 The stoichiometric ratio of the metal elements (wherein x=0.1, y=0.1), that is, according to the ratio of the amount of Y:Ce:Gd:Al is 2.8:0.1:0.1:5, weigh Al 2 o 3 , Y 2 o 3 , CeO 2 and Gd 2 o 3 , and then weigh the equivalent Al 2 o 3 , Y 2 o 3 , CeO 2 and Gd 2 o 3 Total weight 0.5% H 3 BO 3 As a flux, put the weighed reagent in an agate mortar and grind it for 20-60 minutes to make it evenly ground, mix it evenly, and put it into a corundum crucible;

[0047] (2) Put the corundum crucible with reagents into a high-temperature reduction furnace, sinter at 1500°C for 2 hours in a hydrogen reduction atmosphere (or reduction with carbon powder), and then take out the sample after cooling to room temperature with the furnace;

[0048] (3) Grinding the powder obtained by sintering and passing through a 360 mesh sieve to obtain the primary powder;

[0049] (4) Soak the primary powder in nitric acid with a mass percent...

Embodiment 3

[0055] (1) Press Y 3-x-y Ce x Gd y Al 5 o 12 The stoichiometric ratio of metal elements (wherein x=0.4, y=0.4), that is, according to the ratio of the amount of Y:Ce:Gd:Al is 2.2:0.4:0.4:5, weigh Al 2 o 3 , Y 2 o 3 , CeO 2 and Gd 2 o 3 , and then weigh the equivalent Al 2 o 3 , Y 2 o 3 , CeO 2 and Gd 2 o 3 Total weight 3% BaF 2 with H 3 BO 3 mixture (wherein BaF 2 with H 3 BO 3 Mass ratio is 1: 1~15) as fluxing agent, puts the weighed reagent in the agate mortar and grinds 20~60min to make it grind evenly, after it is mixed evenly, packs in the corundum crucible;

[0056] (2) Put the corundum crucible with reagents into a high-temperature reduction furnace, sinter at 1200°C for 5 hours under hydrogen reduction atmosphere (or reduction with carbon powder), and then take out the sample after cooling to room temperature with the furnace;

[0057] (3) Grinding the powder obtained by sintering and passing through a 360 mesh sieve to obtain the primary powder;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| emission peak | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com