Rare earth rubber aging inhibitor and application thereof

A rubber antioxidant and rare earth technology, which is applied to the field of rubber antioxidants containing rare earth substances, can solve problems such as inconvenient storage and transportation, and achieve the effects of low cost, simple production and improved compatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

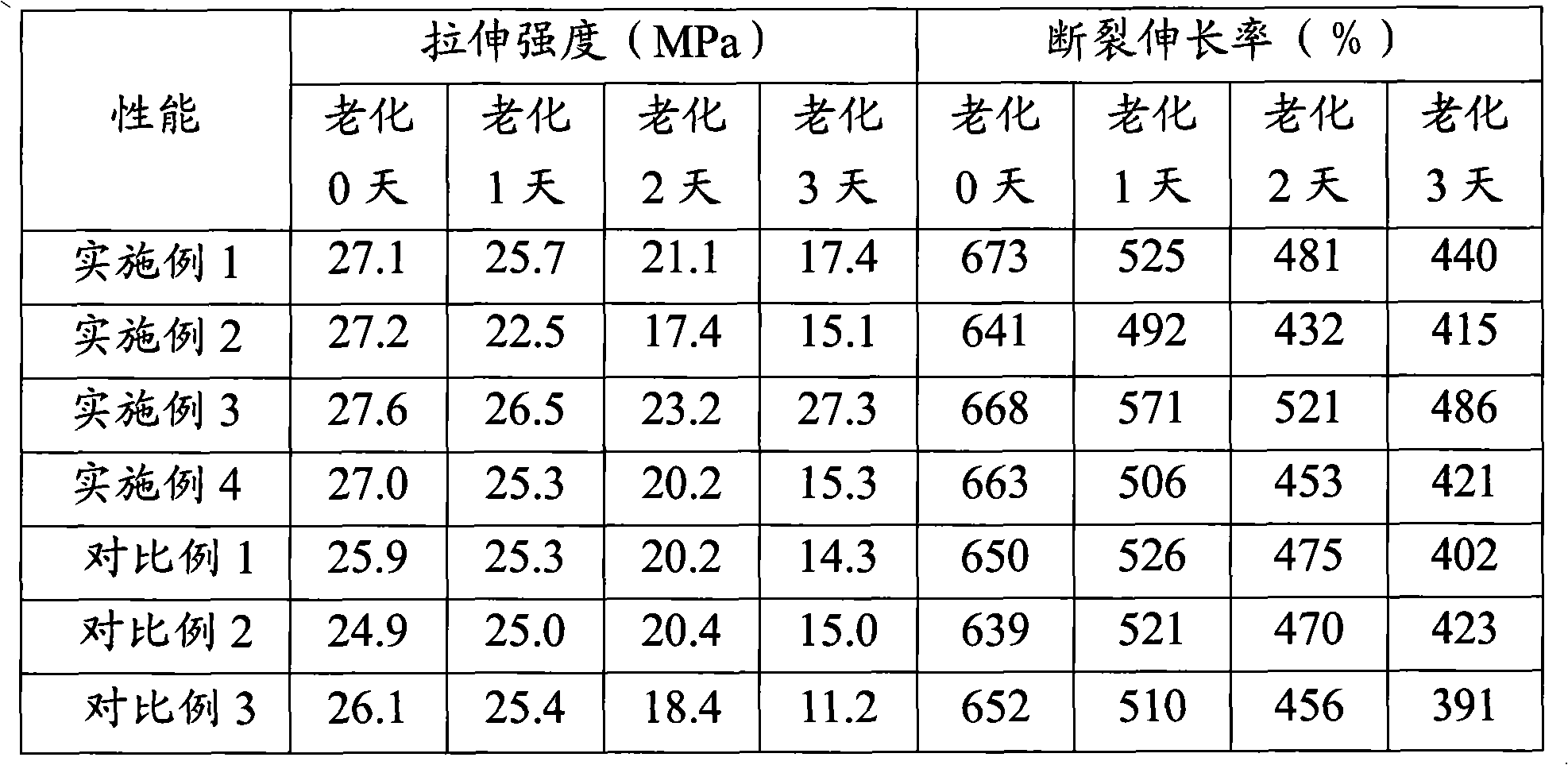

Examples

Embodiment 1

[0033] Commercially available adipic acid and stearic acid are melted at 80-120°C, start the agitator and put in a catalytic amount of glacial acetic acid, after stirring evenly, add La at 80-105°C 2 o 3 React with CaO and pentaerythritol at 105-140°C for 3-3.5 hours, and after purification and other treatments, the rare earth antioxidant WPG (its general formula is LaCa(C 18 h 35 o 2 ) 2.6 (C 5 h 7 o 4 ) 1.3 (C 6 h 8 o 4 ) 0.8 ).

[0034] Thin pass 100 grams of natural rubber 6 times, each time the rubber materials are continuously stacked until all the rubber passes through the double rollers, and then the rubber blocks are turned 90 degrees and placed vertically in the open mixer, and continue processing in this way; after that Add 5 grams of zinc oxide and 2 grams of stearic acid. When the powder is completely eaten, cut a 3 / 4 knife on each side, make a triangle bag, and then add 2 grams of rare earth anti-aging agent WPG. When the powder is completely eaten, c...

Embodiment 2

[0036] Commercially available sebacic acid and epoxy oleic acid are melted at 80-120°C, start the agitator and put in catalytic amount of glacial acetic acid, after stirring evenly, add refined mixed light rare earth oxide (oxidized Lanthanum and cerium oxide) and ZnO and pentaerythritol, react at 105-140°C for 3-3.5 hours, and after purification and other treatments, the rare earth anti-aging agent WPC can be obtained.

[0037] Thin pass 100 grams of natural rubber 6 times, each time the rubber materials are continuously stacked until all the rubber passes through the double rollers, and then the rubber blocks are turned 90 degrees and placed vertically in the open mixer, and continue processing in this way; after that Add 5 grams of zinc oxide and 2 grams of stearic acid. When the powder is completely eaten, cut a 3 / 4 knife on each side, make a triangle bag, and then add 2 grams of rare earth anti-aging agent WPC. When the powder is completely eaten, cut off each side 3 / 4 kn...

Embodiment 3

[0039] Thin pass 100 grams of natural rubber 6 times, each time the rubber materials are continuously stacked until all the rubber passes through the double rollers, and then the rubber blocks are turned 90 degrees and placed vertically in the open mixer, and continue processing in this way; after that Add 5 grams of zinc oxide and 2 grams of stearic acid. When the powder is completely eaten, cut a 3 / 4 knife on each side, make a triangle bag, and then add 3 grams of rare earth anti-aging agent WPG. When the powder is completely eaten, cut off each side 3 / 4 knife at a time, make a triangle bag; then add 1.5 grams of vulcanization accelerator CZ and 0.5 grams of vulcanization accelerator DM until the powder is completely eaten, cut 3 / 4 knife on each side, make a triangle bag; finally add 1.5 Gram sulfur, cut a 3 / 4 knife on each side, make a triangular bag three times, then reduce the roller distance, thin the sheet four times, and place it on the polyester film to stand for 3 hou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com