Process for heat treatment of amorphous transformer core

A technology of heat treatment furnace and process, which is applied in the direction of heat treatment furnace, inductor/transformer/magnet manufacturing, heat treatment equipment, etc. It can solve the problems of increasing grain size and deteriorating magnetic properties of strips, and achieves reduced loss, good magnetic properties, high Effect of flux value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

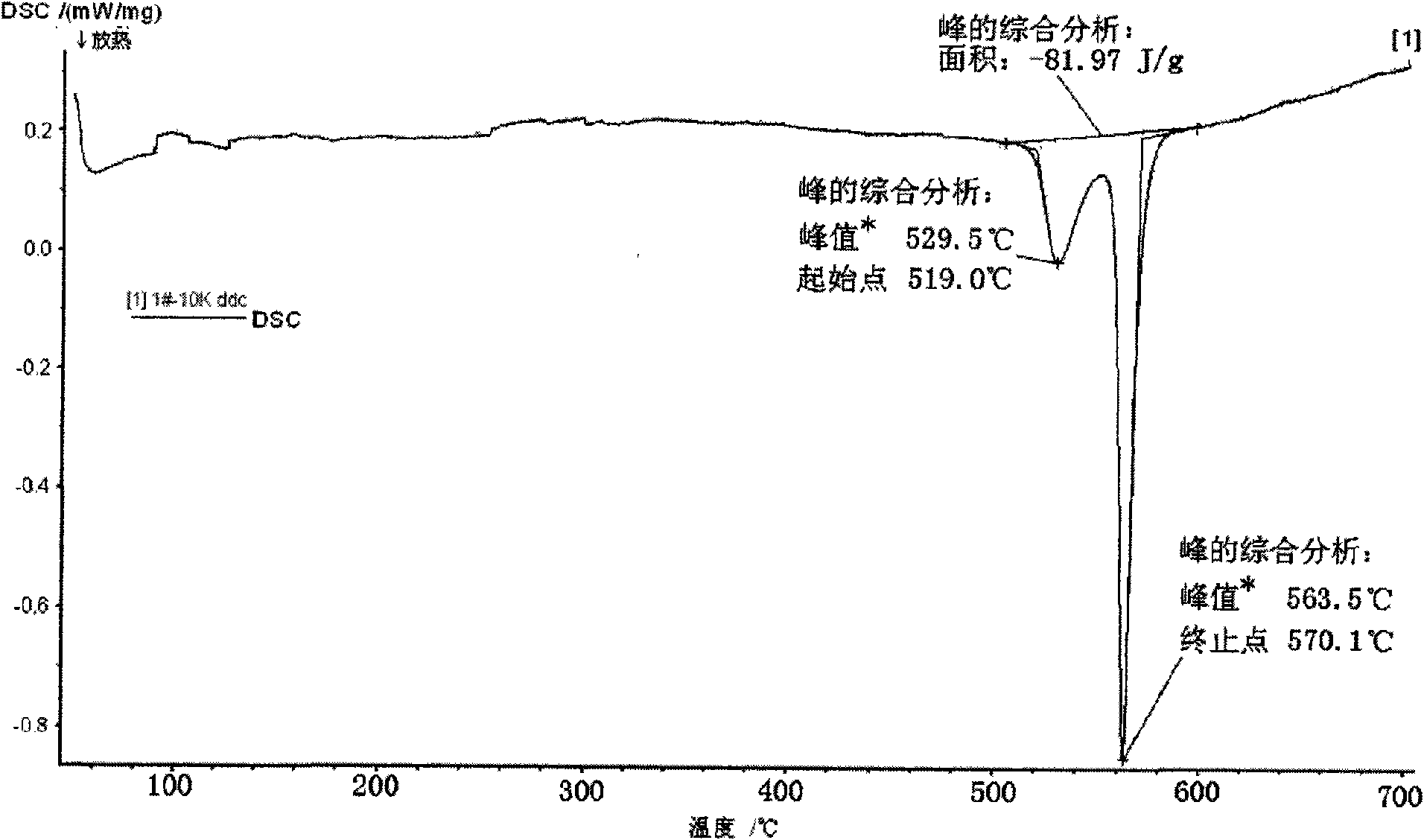

[0024] Such as figure 1 As shown in the DSC curve of a typical amorphous strip, it can be seen that the amorphous has a crystallization peak at 750K and 830K respectively. When heated to around 750K, the crystal phase begins to form inside the isotropic amorphous phase, primary crystallization begins when it exceeds 750K, and secondary crystallization begins when it reaches 830K. The αFe phase produced by primary crystallization, especially the uniform nanoscale αFe phase grains, greatly improves the magnetic properties of the amorphous strip. The secondary crystallization will greatly increase the size of the grains but will deteriorate the magnetic properties of the strip.

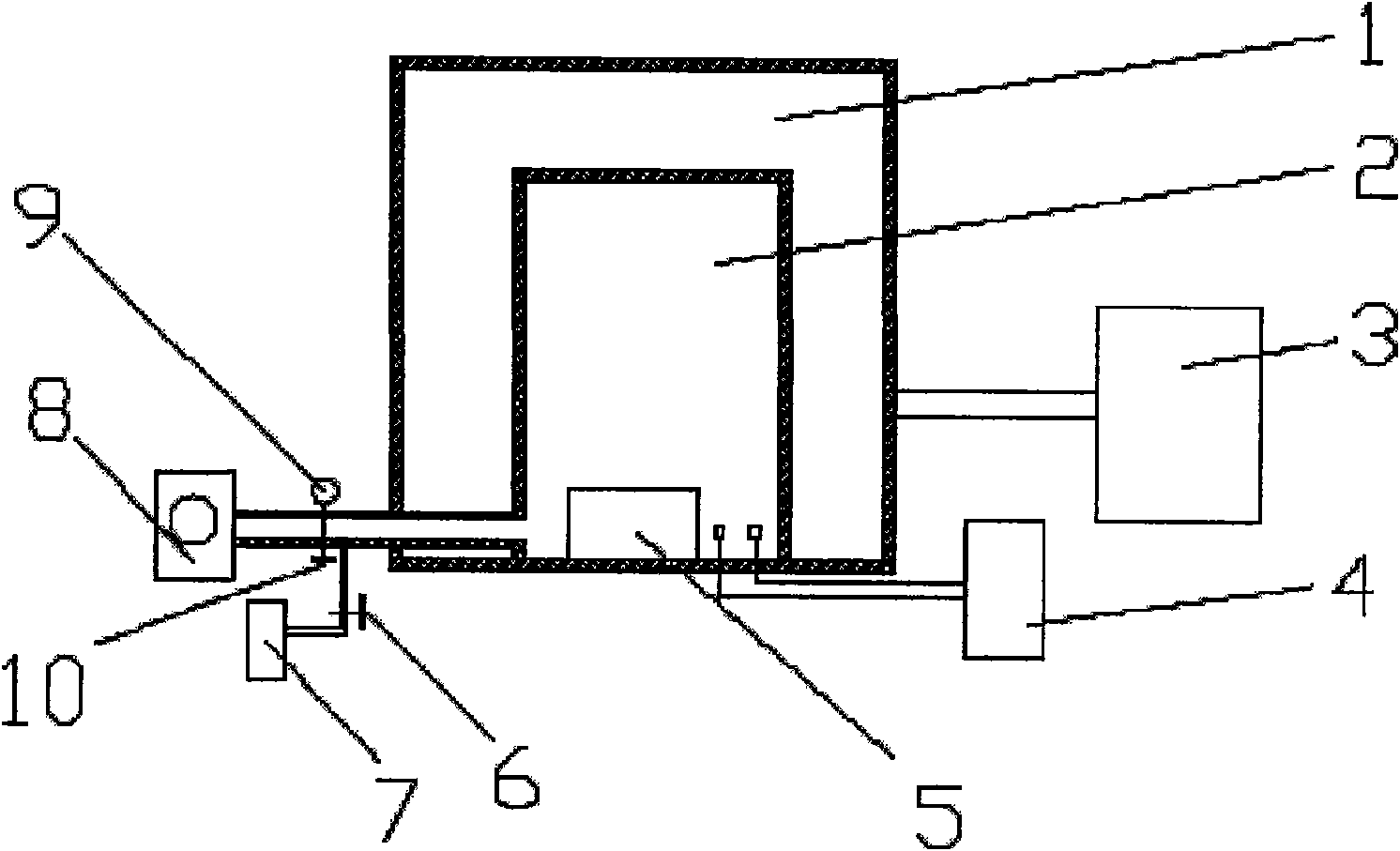

[0025] Such as figure 2 The shown heat treatment furnace is composed of heat treatment furnace heating chamber 1, heat treatment furnace vacuum chamber 2, heating temperature control device 3, magnetizing equipment 4, stage 5, nitrogen bottle 7, vacuum pump 8 and pressure gauge 9, wherein: heat treatm...

Embodiment 2

[0031] Put the wound domestic amorphous iron core into the vacuum chamber 2 of the heat treatment furnace, wind 6 turns of 10mm in diameter enamelled insulated thick copper wire, and cover the furnace cover. Open the valve 10 and the vacuum pump 8, stop the vacuum pump 8 when the vacuum reaches -0.1MPa, and close the valve 10 leading to the vacuum pump 8. Open valve 6 and nitrogen bottle 7 afterwards, charge nitrogen, until nitrogen pressure is 0.5MPa, then close nitrogen bottle 7 and valve 6. Set the heating curve so that the heating rate is set at 5 °C / min, the holding temperature is 500 °C, and the holding time is 1.5 hours. Start the heating and temperature control device 3 to start heating up, and start to keep warm after reaching the holding temperature of 500°C, and add a longitudinal magnetic field of 3V100A during the holding period; The surface of the iron core is coated with epoxy resin. The thickness of the coated epoxy resin is 1mm. The epoxy resin should complet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| no-load loss | aaaaa | aaaaa |

| no-load loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com