Ion-doped tin dioxide porous film type gas sensitive device and method for manufacturing same

A technology of tin dioxide and porous film, which is applied in semiconductor/solid-state device manufacturing, electrical components, instruments, etc. It can solve the problems of poor selectivity and high working temperature, and achieve the effect of less equipment, low working temperature and fast response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

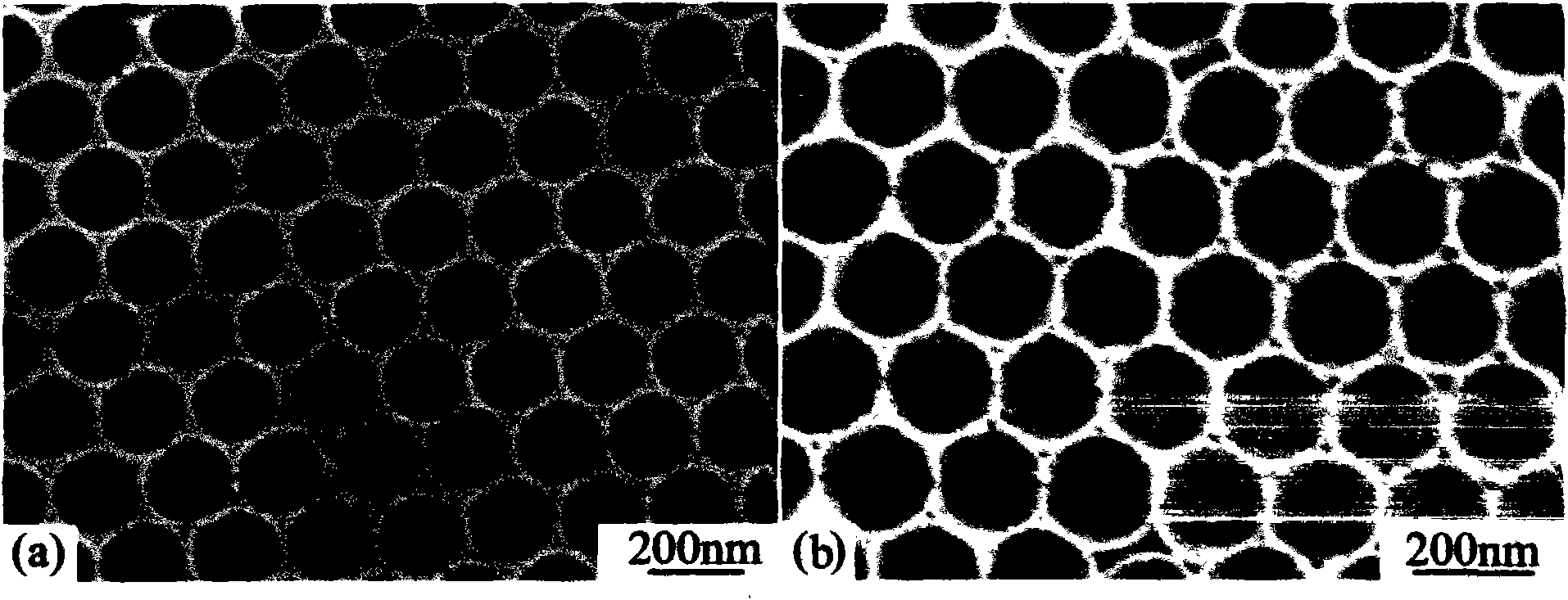

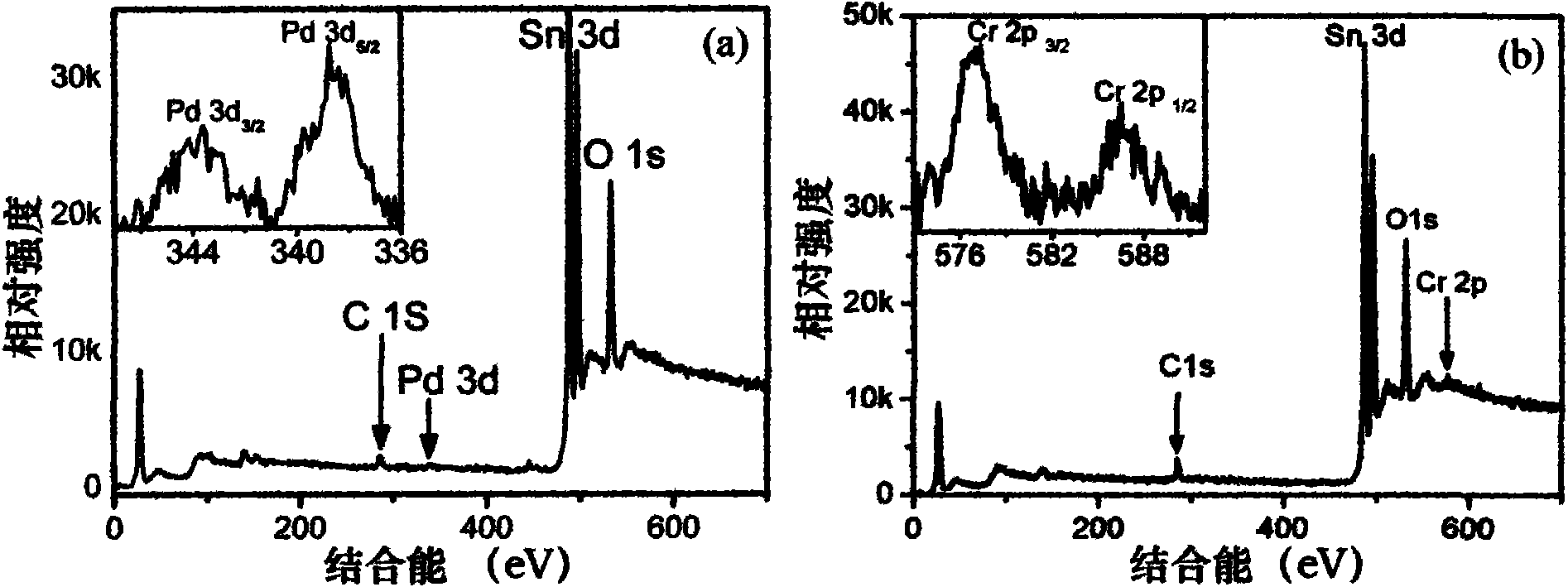

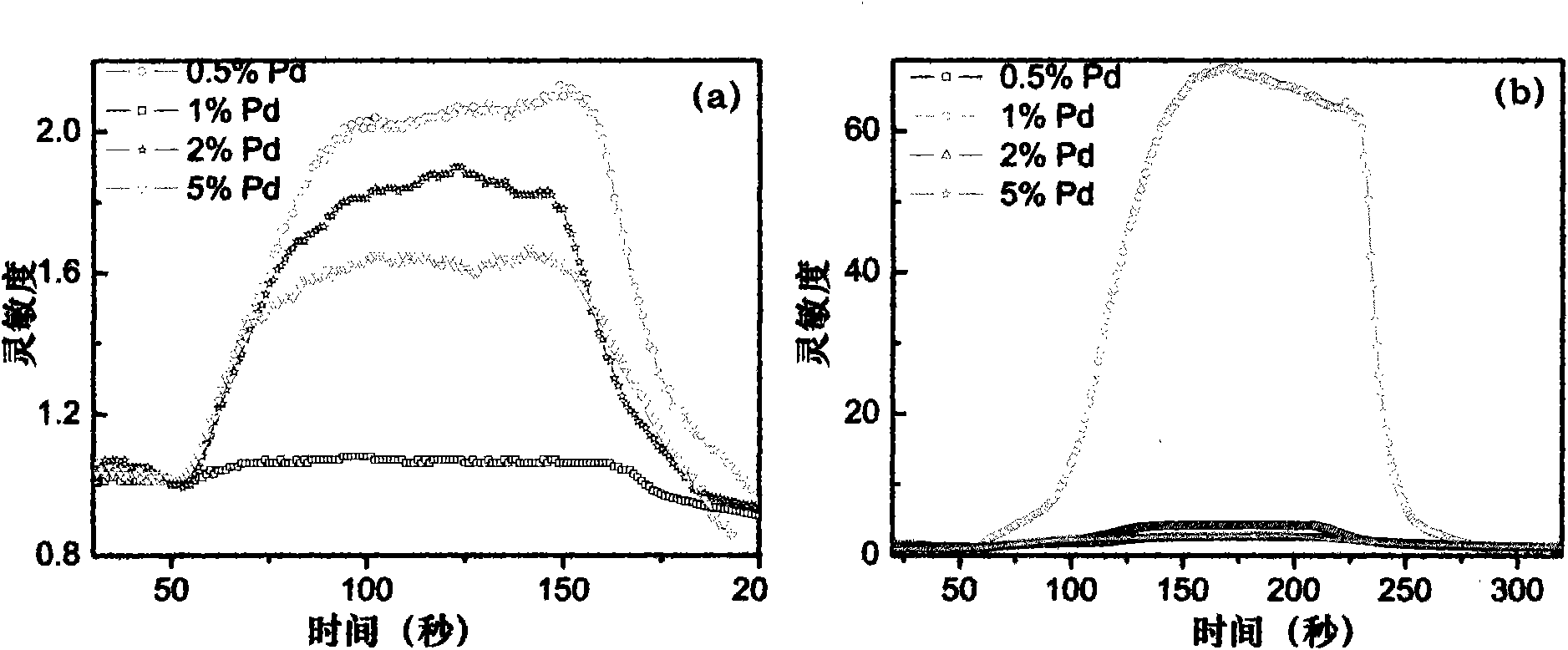

[0019] The specific steps of preparation are as follows: first, the polystyrene colloidal spheres with a diameter of 200 nm are attached to the surface of the substrate by a spin coating method to form a single-layer colloidal crystal template. Then, in the first step, adding palladium dichloride to obtain a precursor solution in the tin tetrachloride solution whose concentration is 0.05M; wherein, the palladium ion in the palladium dichloride and the tin ion in the tin tetrachloride solution The molar ratio is 0.005:1. In the second step, the single-layer colloidal crystal template is first immersed in the precursor solution, and after it is detached from the substrate and floats on the surface of the precursor solution, the single-layer colloidal crystal is picked up with a substrate with electrodes of the desired shape, and Make it cover the surface of the substrate, and then heat the substrate covered with a single layer of colloidal crystals and soaked in the precursor so...

Embodiment 2

[0021] The specific steps of preparation are as follows: first, the polystyrene colloidal spheres with a diameter of 200 nm are attached to the surface of the substrate by a spin coating method to form a single-layer colloidal crystal template. Then, in the first step, adding palladium dichloride to obtain a precursor solution in the tin tetrachloride solution whose concentration is 0.08M; wherein, the palladium ion in the palladium dichloride and the tin ion in the tin tetrachloride solution The molar ratio is 0.01:1. In the second step, the single-layer colloidal crystal template is first immersed in the precursor solution, and after it is detached from the substrate and floats on the surface of the precursor solution, the single-layer colloidal crystal is picked up with a substrate with electrodes of the desired shape, and Make it cover the surface of the substrate, and then heat the substrate covered with a single layer of colloidal crystals and soaked in the precursor sol...

Embodiment 3

[0023] The specific steps of preparation are as follows: first, the polystyrene colloidal spheres with a diameter of 200 nm are attached to the surface of the substrate by a spin coating method to form a single-layer colloidal crystal template. Then, in the first step, add palladium dichloride to obtain a precursor solution in the tin tetrachloride solution that concentration is 0.1M; Wherein, the palladium ion in the palladium dichloride and the tin ion in the tin tetrachloride solution The molar ratio is 0.03:1. In the second step, the single-layer colloidal crystal template is first immersed in the precursor solution, and after it is detached from the substrate and floats on the surface of the precursor solution, the single-layer colloidal crystal is picked up with a substrate with electrodes of the desired shape, and Make it cover the surface of the substrate, and then heat the substrate covered with a single layer of colloidal crystals and soaked in the precursor solution...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com