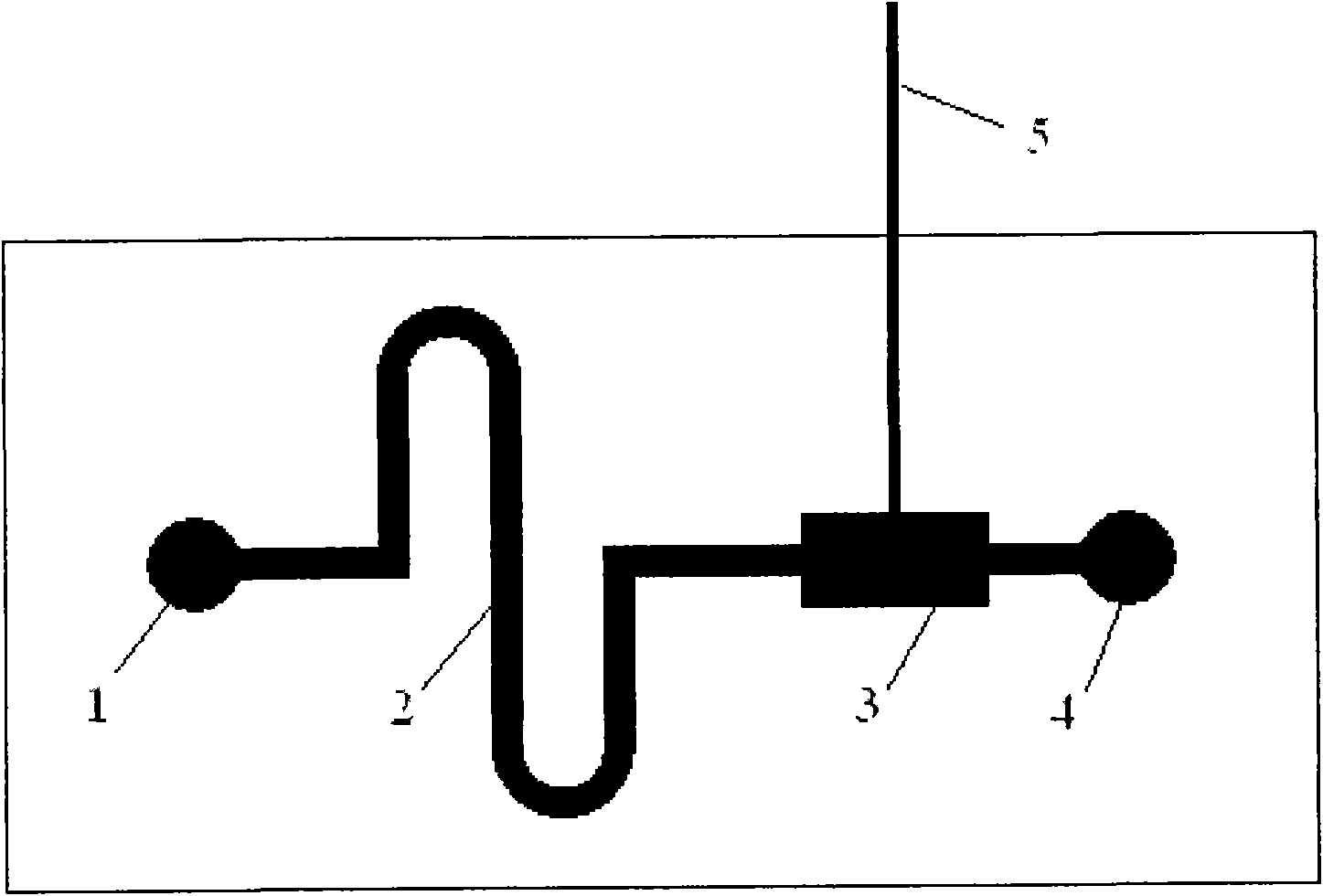

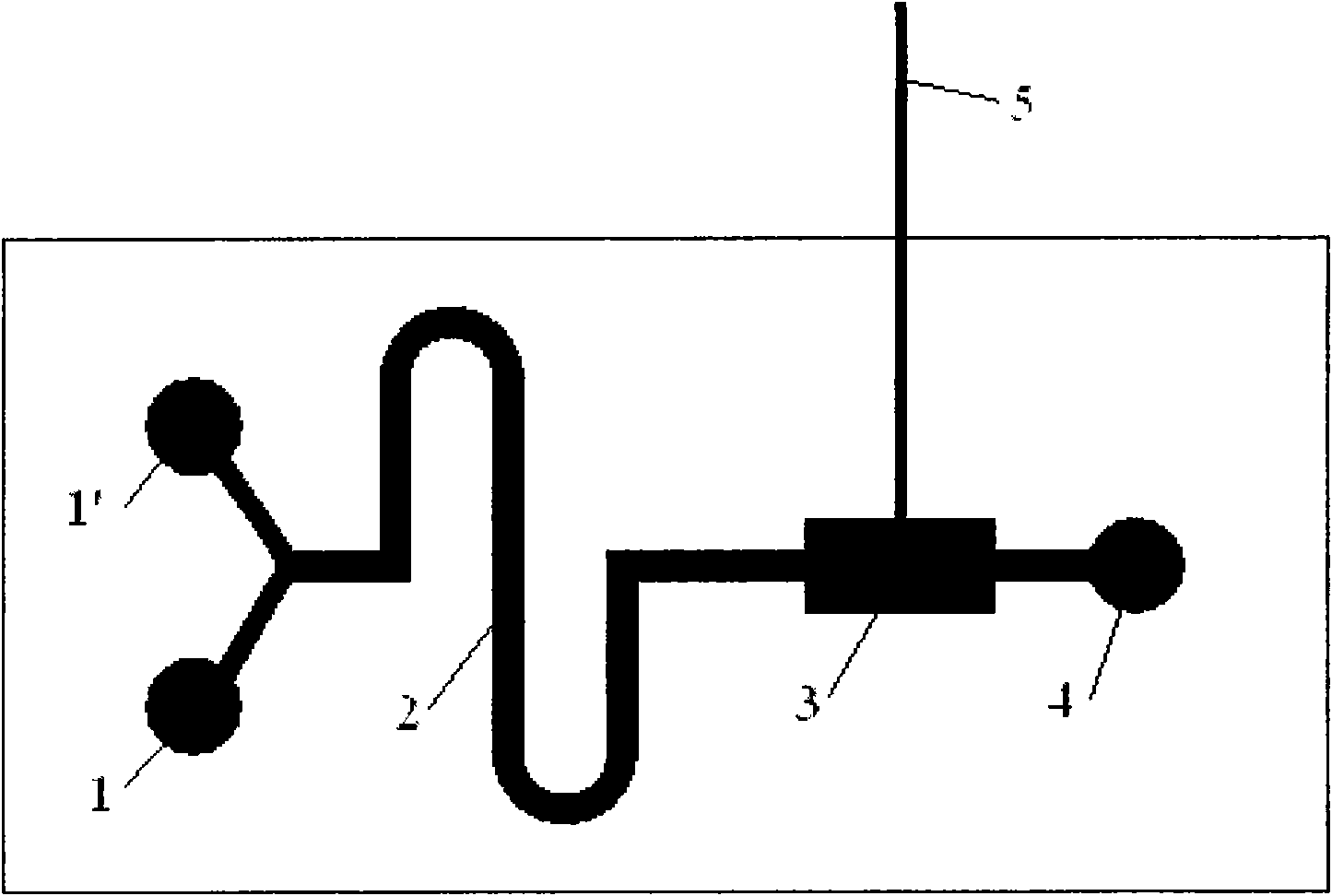

Integrated micro-fluidic chip system

A microfluidic chip and sample injection technology, applied in the field of microfluidic chips and their systems, and integrated microfluidic chip systems, can solve the problems of large consumption of reagents and samples, complicated operations, etc., and achieve fast analysis speed and high sensitivity. , Analyze the effect of process automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

test approach 1

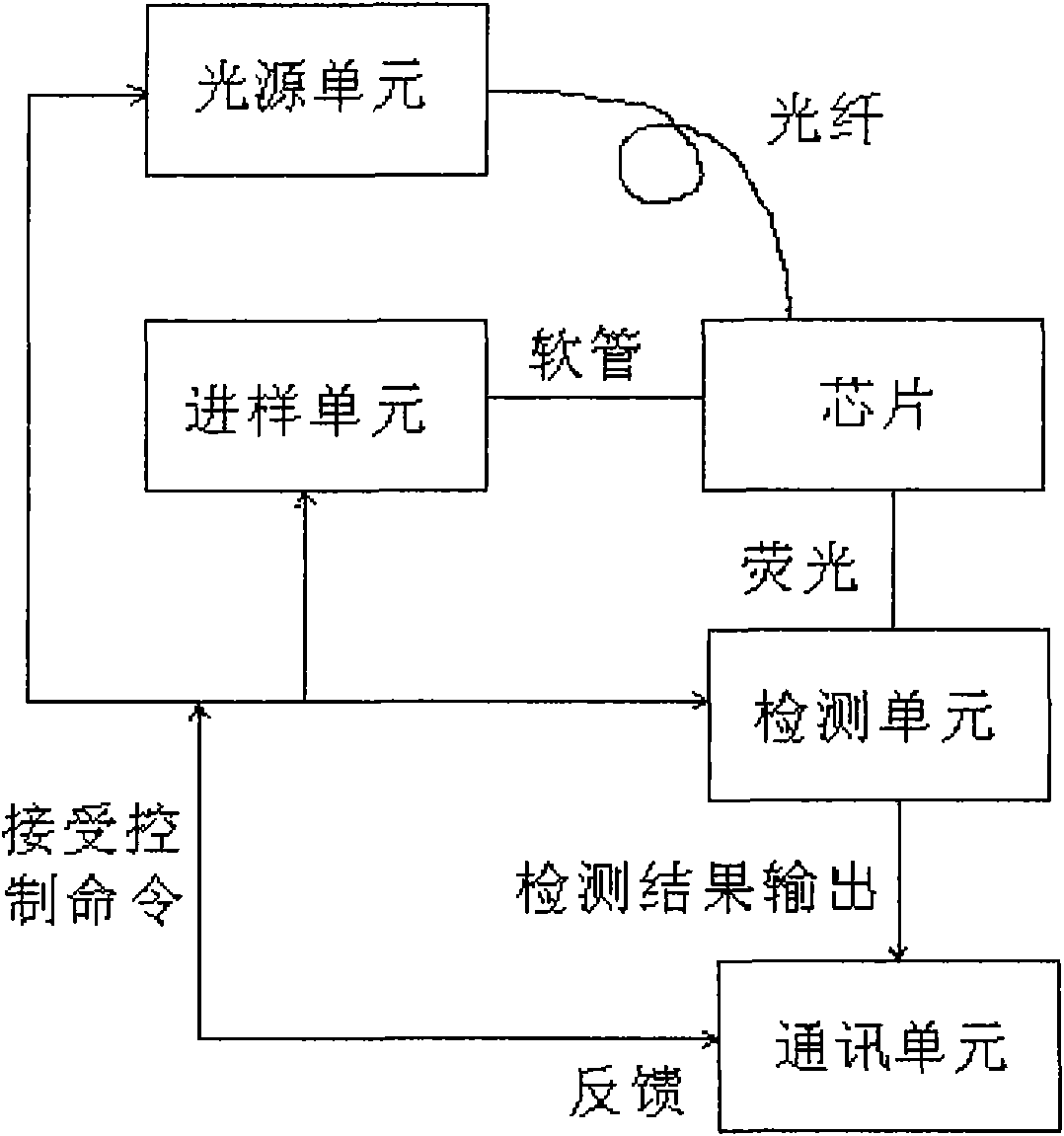

[0054] (1) Directly use the control panel on the microfluidic chip system to issue control commands: turn on the power supply, LED light source and photomultiplier tube in turn, and the LED excitation light is transmitted to the detection area of the microfluidic chip through optical fibers;

[0055] (2) Directly use the control panel on the microfluidic chip system to issue a pump start command, and the fluorescent substance (FITC standard solution) is introduced into the chip from the injection port under the drive of the pump;

[0056] (3) When flowing through the detection area, directly use the control panel on the microfluidic chip system to issue a pump shutdown command, the pump stops, and the detection unit detects the fluorescent light intensity (relative light intensity), and detects for 1 minute;

[0057] (4) The communication unit receives the detection result sent by the detection unit, and directly displays it on the display screen on the microfluidic chip syst...

test approach 2

[0062] (1) The computer control program is used to issue control commands: turn on the power supply, LED light source and photomultiplier tube in turn, and the LED excitation light is transmitted to the detection area of the microfluidic chip through the optical fiber;

[0063] (2) The computer control program is used to issue a pump start command, and the fluorescent substance (FITC standard solution) is introduced into the microfluidic chip from the injection port under the drive of the pump;

[0064] (3) When flowing through the detection area, the program control issues a command to shut down the pump, the pump stops, and the detection unit detects the fluorescent light intensity (relative light intensity), and detects for 1 minute;

[0065] (4) The communication unit receives the detection result sent by the detection unit and transmits it to the computer;

[0066] (5) The program control issues a pump-on command, and after the solution flows out of the chip, the progra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com