Preparing method of ceram site fully using biosolid and sludge

A technology of biological sludge and silt, which is applied in the field of making ceramsite and completely using biological sludge and silt to make ceramsite, can solve the problems that cannot be realized, and achieve the effects of low cost, good fire resistance, and good heat insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

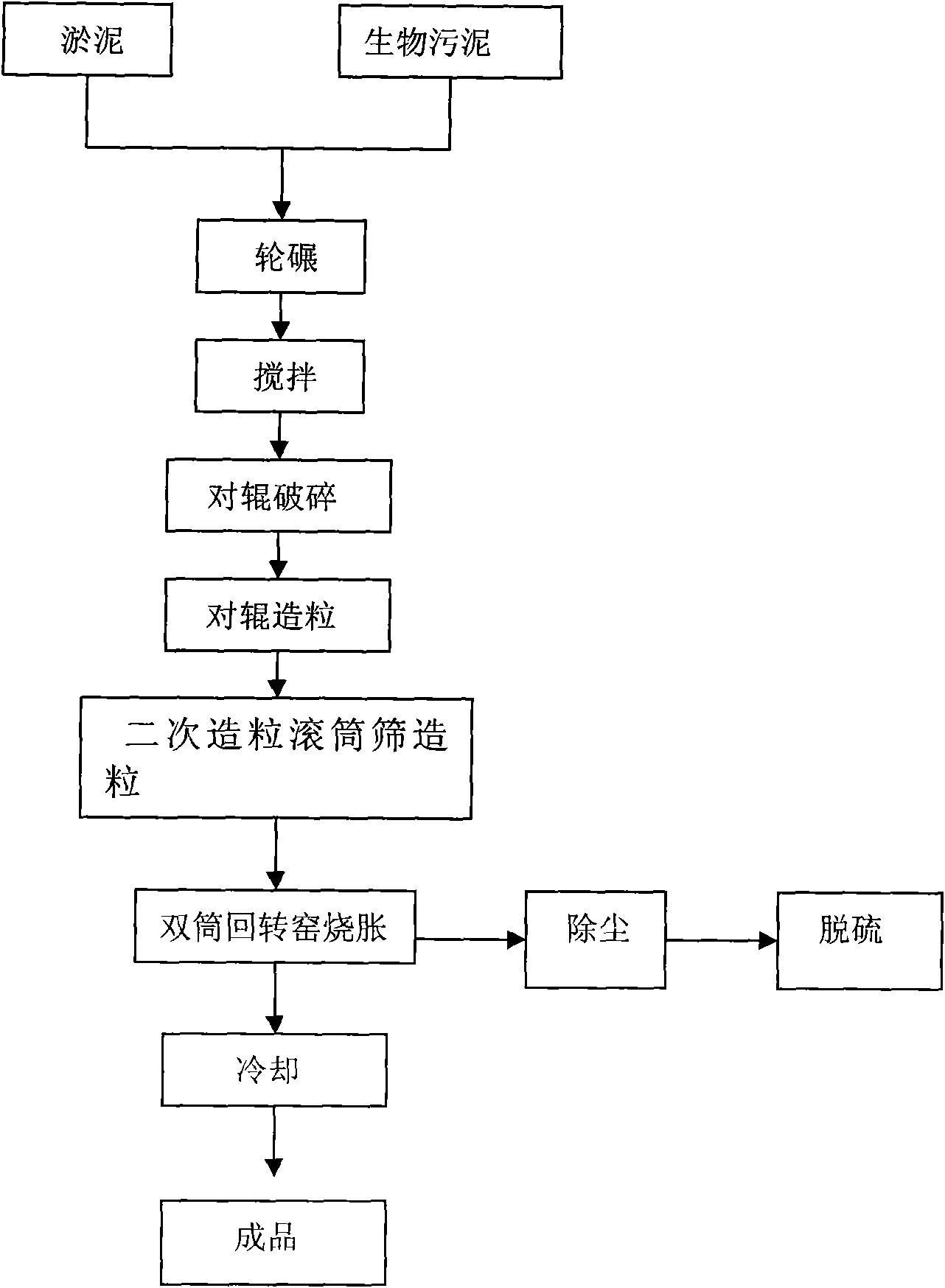

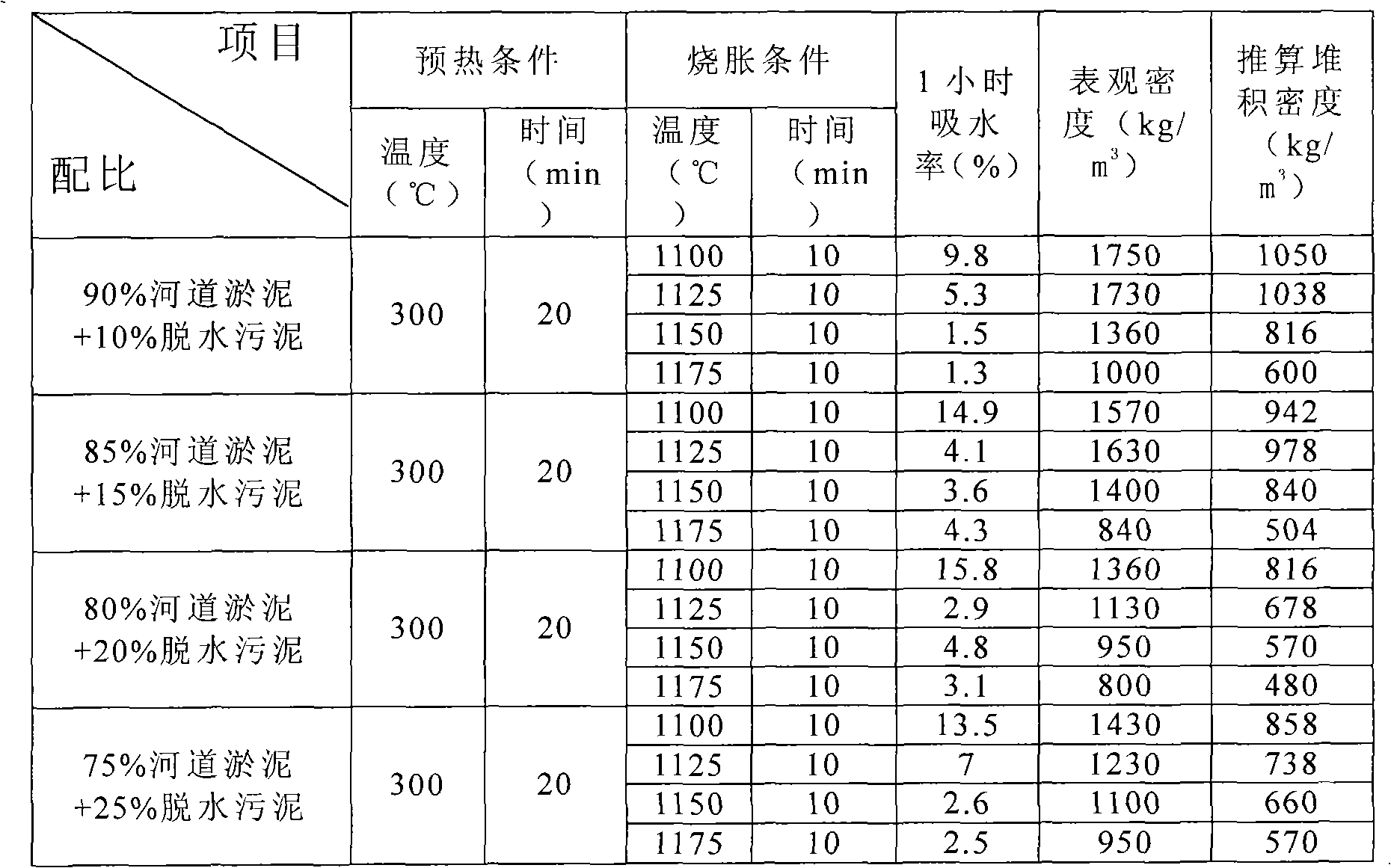

[0046] Such as figure 1 As shown, according to the proportion of Example 1 in Table 7, the river silt and the formula of dewatered sludge were evenly mixed, placed for aging at room temperature, and placed for 7 days for partial dehydration. After dehydration, the water content of the river silt and dewatered sludge was 41.5 %, through the feeder into the twin-shaft mixer for full mixing, the mixing time is 20 minutes; then the biological sludge and sludge after the above mixing are crushed in the roller crusher, the crushing time is 1 minute , carry out secondary granulation after crushing, for the first time use the roller granulator to granulate the rollers for 4 minutes, and for the second time use the granulation drum to granulate for 6 minutes, the particle size of the granules after the secondary granulation is 5- 15mm. Put the above-mentioned granulated pellets into a double-cylinder rotary kiln for preheating, the preheating temperature is 250°C, and the preheating t...

Embodiment 2-4

[0047] Example 2-4, according to the ratio of Example 2-4 in Table 7, the river silt and the formula of dewatered sludge were evenly mixed, placed for aging at room temperature, and placed for 7 days for partial dehydration. After dehydration, the river silt and dewatered sludge The moisture content is 40-45%, and other technical processes are the same as embodiment 1, no longer repeat them.

Embodiment 5

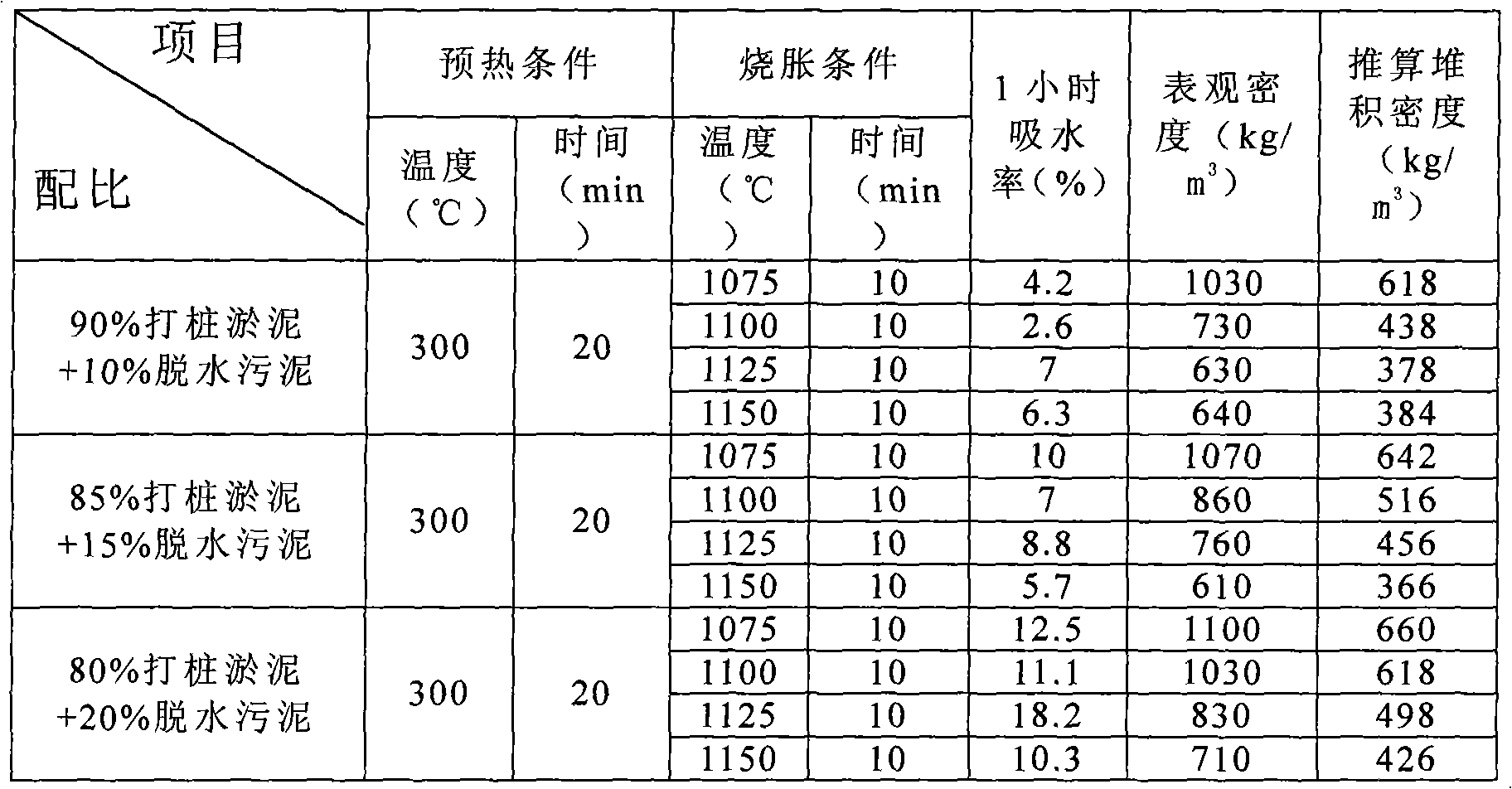

[0049] According to the proportion of embodiment 5 in table 7, the piling sludge and the formula of dewatered sludge are evenly mixed, placed for aging at normal temperature, and placed for 7 days to carry out partial dehydration. After dehydration, the water content of river sludge and dewatered sludge is 34.2%. The feeder is put into the double-shaft mixer for full mixing, and the mixing time is 5 minutes; then the biological sludge and sludge after the above mixing are crushed in the roller crusher, and the crushing time is 5 minutes. Carry out secondary granulation, the first time using a roller granulator to granulate for 6 minutes, and the second time using a granulation drum for 4 minutes, and the particle size of the granular material after the secondary granulation is 2-15mm.

[0050] Put the above-mentioned granulated pellets into a double-cylinder rotary kiln for preheating, the preheating temperature is 400°C, and the preheating time is 15 minutes; Minutes; After t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com