Fiberguide grating sensor and manufacturing method thereof

A technology of grating sensor and optical fiber waveguide, which is used in optical waveguide light guide, transmission of sensing components using optical devices, fluid pressure measurement using optical methods, etc. To achieve the effect of high sensitivity, strong high temperature resistance, good measurement accuracy and multiplexing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] A method for manufacturing an optical fiber waveguide grating sensor, comprising the following steps:

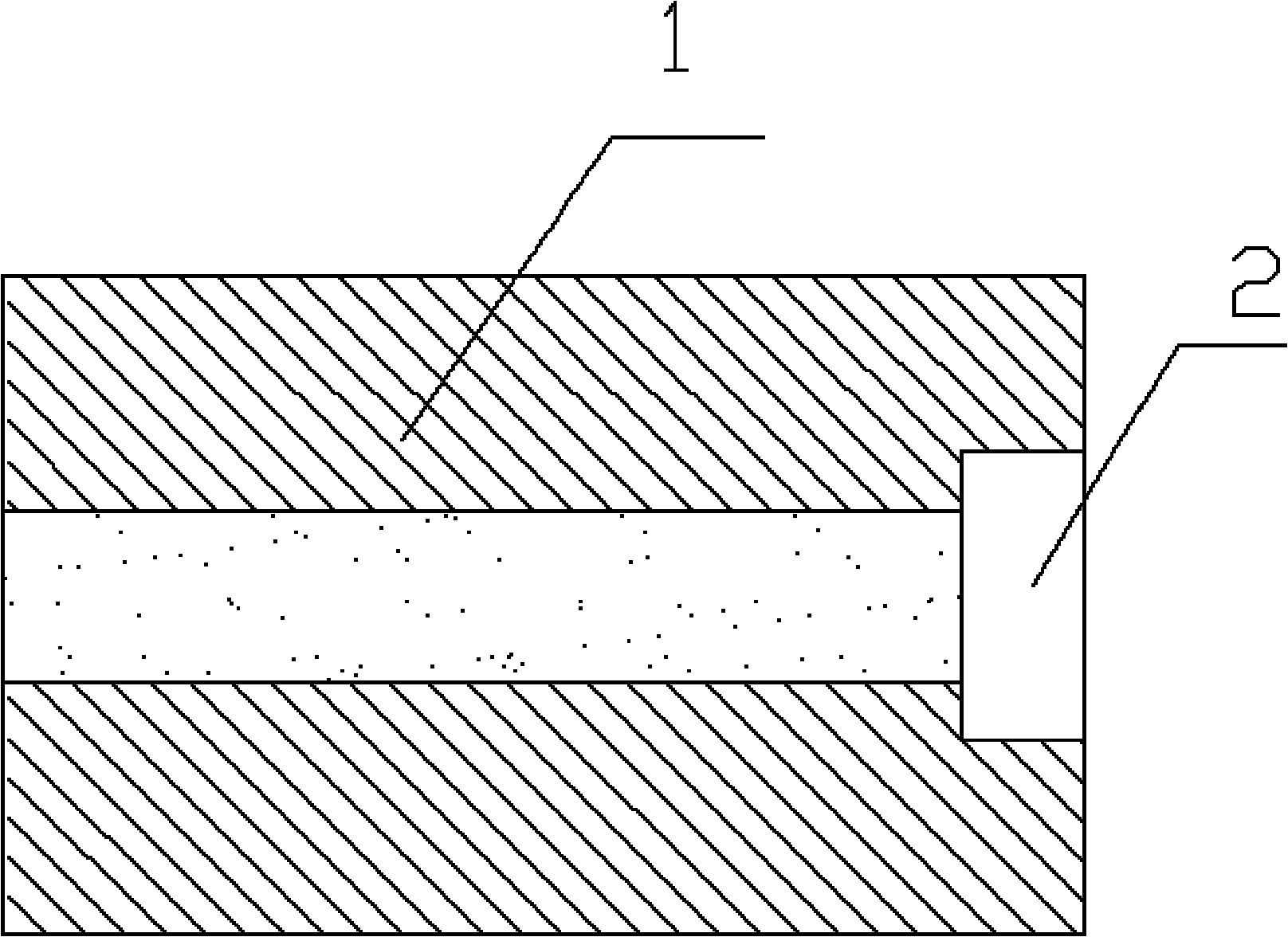

[0016] Step 1. Laser machining a groove 2 on the end face of the optical fiber 1, such as figure 1 shown;

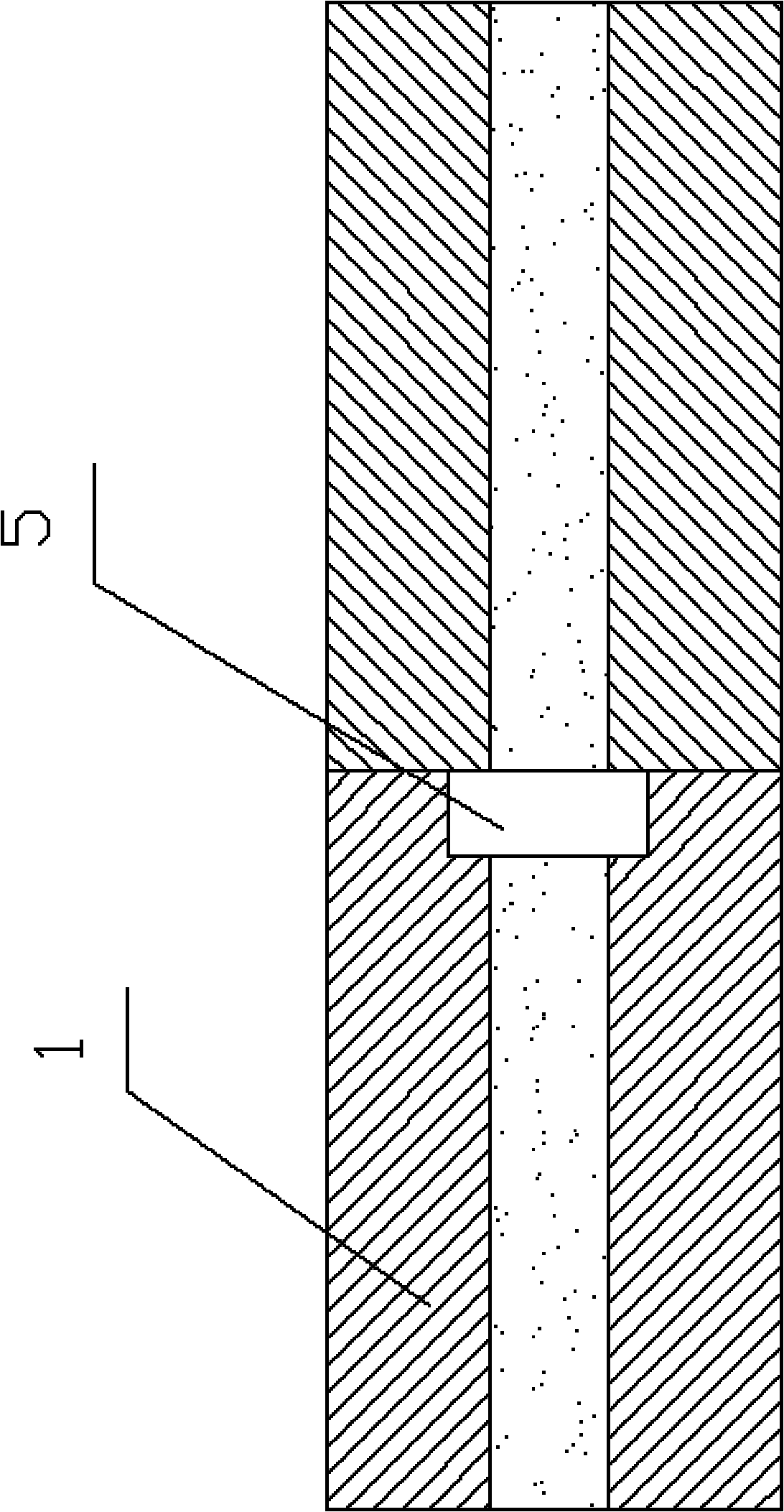

[0017] Step 2. Splice a section of connected optical fiber outside the groove 2 processed in step 1. The groove 2 forms a cavity 5, such as figure 2 shown;

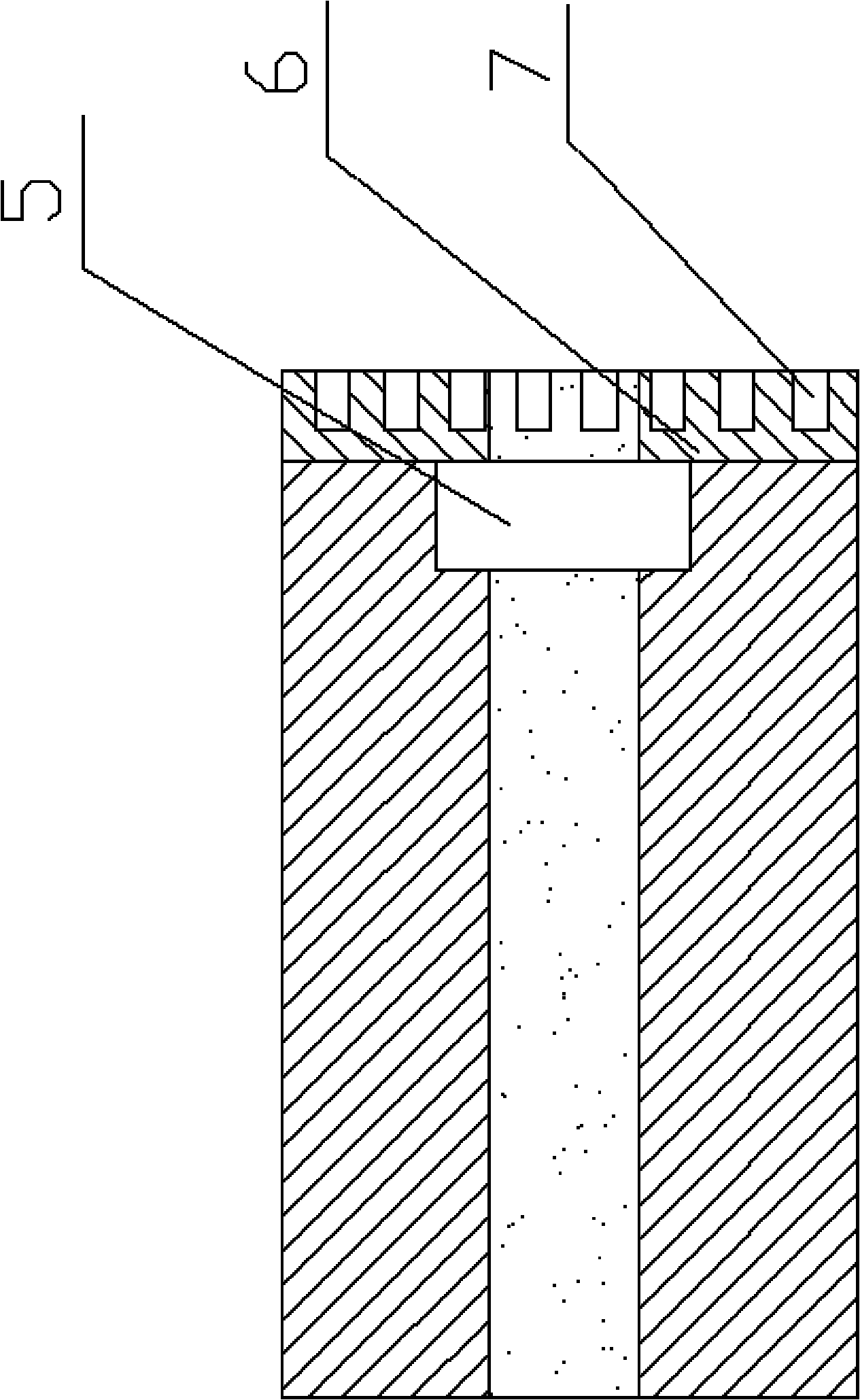

[0018] Step 3: Cut the connected optical fiber on the outer end face of the cavity 5 to form a waveguide diaphragm 6, and then process a plurality of periodic microgrooves 7 on the waveguide diaphragm 6 to form a periodic waveguide grating structure, and thus the present invention is produced. Fiber-optic waveguide grating sensors, such as image 3 As shown, the fiber optic sensor can be used to measure parameters such as temperature, refractive index and pressure.

Embodiment 2

[0020] On the basis of step 3 of embodiment 1, there is also step 4, welding the protective optical fiber 8 with a microgroove on the end face of the waveguide diaphragm 6 to protect the waveguide diaphragm 6, and the optical fiber waveguide of the present invention is produced Grating sensors such as Figure 4 shown. Compared with Example 1, this structure is more resistant to external interference, and there is no cross-sensitivity between refractive index and pressure.

Embodiment 3

[0022] A method for manufacturing an optical fiber waveguide grating sensor, comprising the following steps:

[0023] Step 1. Weld a section of hollow fiber on the end face of fiber 1, and then cut the hollow fiber to form groove 2 in the fiber core, such as Figure 5 shown;

[0024] Step 2 and step 3 are the same as in Embodiment 1, and the fiber waveguide grating sensor of the present invention is produced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com