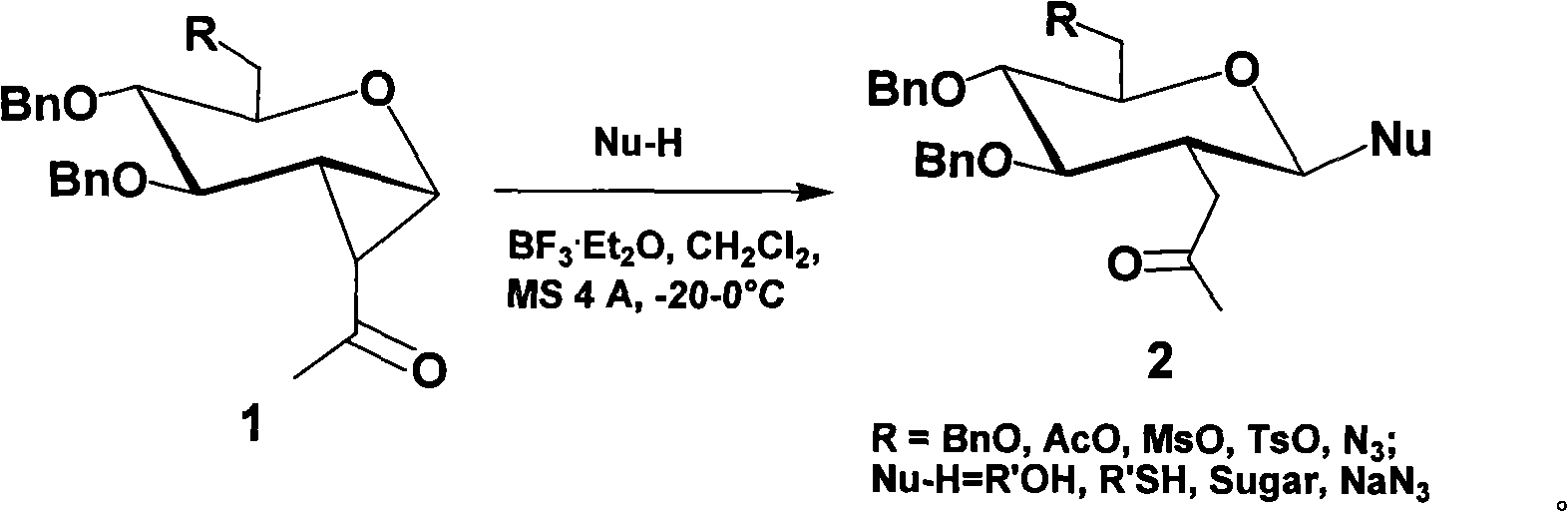

Preparation method of 2-C-acetonyl-2-deoxy-glucoside compounds

A technology of acetylmethyl and glucoside, which is applied in the field of preparation of 2-C-acetylmethyl-2-deoxy-glucoside compounds, can solve the problems of high cost, rare reagents, environmental pollution, etc., and achieve short reaction time , less environmental pollution and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1: Under nitrogen protection, 1,2-deoxy-7-C-acetyl-α-D-glucopyranose derivatives (1,R=BnO, 47mg, 0.1mmol) were added to a 5mL round bottom flask and 1,2:3,4-O-diisopropylidene-α-D-galactopyranose (26mg, 0.1mmol), add dry dichloromethane (1mL) to dissolve, then add to activate Molecular sieves (47 mg), stirred at room temperature for 1 hour, then lowered the reaction temperature to -20°C, added boron trifluoride ether (2.5 μL, 0.02 mmol), and slowly raised the temperature to react, and the reaction was detected by TLC until the end. Add an appropriate amount of triethylamine to quench the reaction, dilute the reaction system with dichloromethane (5mL), filter, and pass the filtrate through water (10mL×2), saturated aqueous sodium bicarbonate (10mL×2) and saturated brine (10mL×2) Washed and dried over anhydrous sodium sulfate. After filtration, the filtrate was concentrated and purified by silica gel column chromatography (eluent: petroleum ether / ethyl acetate 3...

Embodiment 2

[0030] Example 2: Under nitrogen protection, 1,2-deoxy-7-C-acetyl-α-D-glucopyranose derivative (1,R=BnO, 59mg, 0.125mmol) was added to a 5mL round bottom flask and 1,2:3,4-O-diisopropylidene-α-D-galactopyranose (26mg, 0.1mmol), add dry dichloromethane (1mL) to dissolve, then add to activate Molecular sieves (47 mg), stirred at room temperature for 1 hour, then lowered the reaction temperature to -20°C, added boron trifluoride ether (3.2 μL, 0.025 mmol), and slowly raised the temperature to react, and the reaction was detected by TLC until the end. Add an appropriate amount of triethylamine to quench the reaction, dilute the reaction system with dichloromethane (5mL), filter, and pass the filtrate through water (10mL×2), saturated aqueous sodium bicarbonate (10mL×2) and saturated brine (10mL×2) Washed and dried over anhydrous sodium sulfate. After filtration, the filtrate was concentrated and purified by silica gel column chromatography (eluent: petroleum ether / ethyl acetate ...

Embodiment 3

[0031] Example 3: Under nitrogen protection, 1,2-deoxy-7-C-acetyl-α-D-glucopyranose derivatives (1, R=BnO, 38mg, 0.08mmol) were added to a 5mL round bottom flask and 1,2:3,4-O-diisopropylidene-α-D-galactopyranose (26mg, 0.1mmol), add dry dichloromethane (1mL) to dissolve, then add to activate Molecular sieves (47mg) were stirred at room temperature for 1 hour, then the reaction temperature was lowered to -20°C, boron trifluoride ether (2.0 μL, 0.016 mmol) was added, the temperature was raised slowly, and the reaction was detected by TLC until the end. Add an appropriate amount of triethylamine to quench the reaction, dilute the reaction system with dichloromethane (5mL), filter, and pass the filtrate through water (10mL×2), saturated aqueous sodium bicarbonate (10mL×2) and saturated brine (10mL×2) Washed and dried over anhydrous sodium sulfate. After filtration, the filtrate was concentrated and purified by silica gel column chromatography (eluent: petroleum ether / ethyl acet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com