Desulfuration method of environmental-friendly liquefied petroleum gas

A liquefied petroleum gas, environmentally friendly technology, applied in chemical instruments and methods, separation methods, petroleum industry, etc., to achieve the effect of simple equipment, high flow rate, and solving the bottleneck of processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

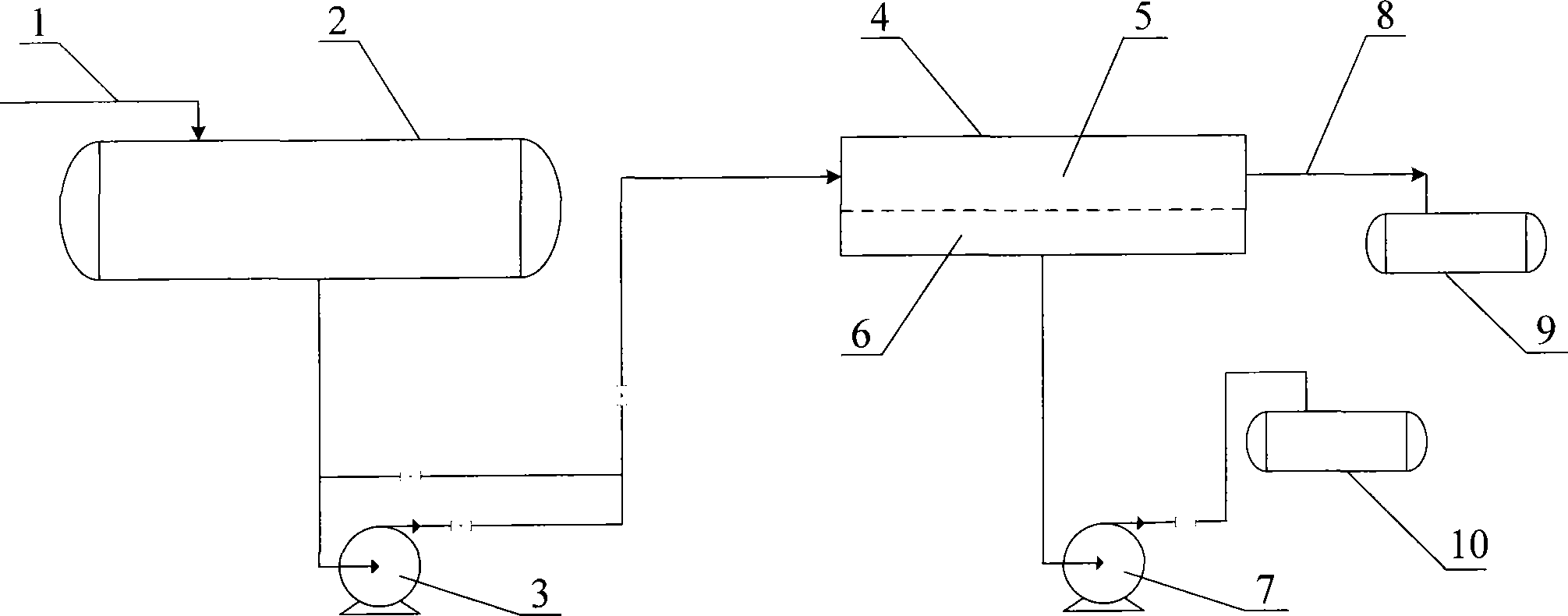

Method used

Image

Examples

Embodiment 1

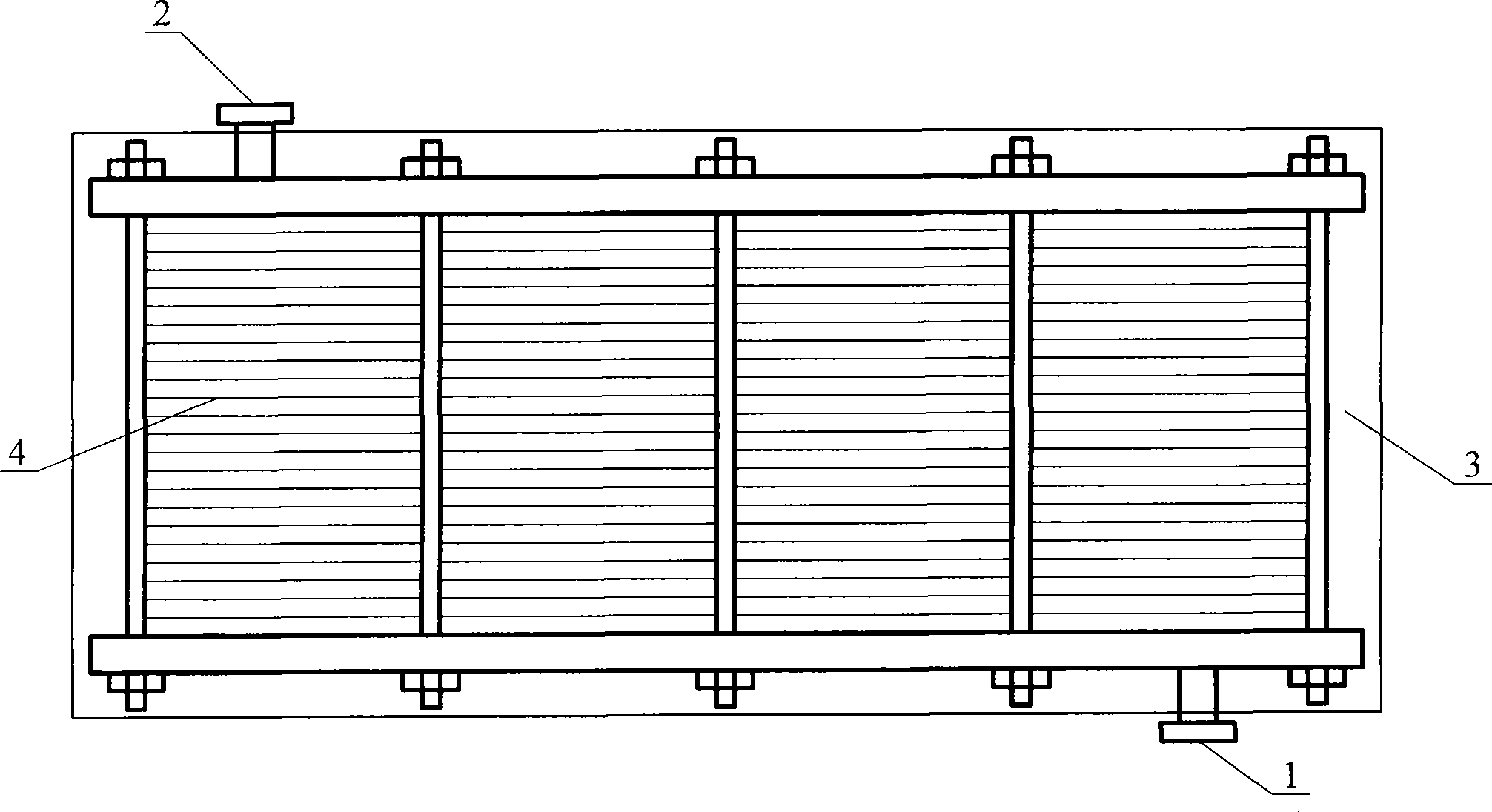

[0037] The raw material is catalytic liquefied petroleum gas containing 39ppm hydrogen sulfide, 320ppm mercaptan sulfur, and 51ppm carbonyl sulfide sulfur. It enters the membrane device through the raw material pump at an operating pressure of 0.8 MPa (MPa) and an operating temperature of 30°C, and passes through the plate frame. Separation of composite membrane composed of polyvinylidene fluoride-based membrane and polyhydroxyl-terminated polybutadiene-acrylonitrile membrane, 99.03% refined liquefied petroleum gas is obtained on the retentate side of the membrane device, and the hydrogen sulfide sulfur content is 1ppm , mercaptan sulfur content 4ppm, carbonyl sulfide sulfur 1ppm; get 0.97% sulfide-rich liquefied petroleum gas on the permeation side of the membrane device, hydrogen sulfide content 3928ppm, mercaptan sulfur content 32581ppm, carbonyl sulfide 5155ppm .

Embodiment 2

[0039] The raw material is coking liquefied petroleum gas containing 30ppm hydrogen sulfide, 2000ppm mercaptan sulfur, and 30ppm3 carbonyl sulfide sulfur. It enters the membrane device through the raw material pump at an operating pressure of 0.8 MPa (MPa) and an operating temperature of 30°C, and passes through the plate frame. The composite membrane composed of polyvinylidene fluoride-based membrane and polyhydroxyl-terminated polybutadiene-acrylonitrile membrane of the type membrane device is separated, and 99.17% of refined liquefied petroleum gas is obtained on the retentate side of the membrane device, the hydrogen sulfide content is 1ppm, and the sulfur content is 1ppm. Alcohol sulfur content is 5ppm, carbonyl sulfide sulfur content is 1ppm; 0.83% sulfide-rich liquefied petroleum gas is obtained on the permeation side of the membrane device, hydrogen sulfide content is 3542ppm, mercaptan sulfur content is 240366ppm, and carbonyl sulfide sulfur content is 3483ppm.

Embodiment 3

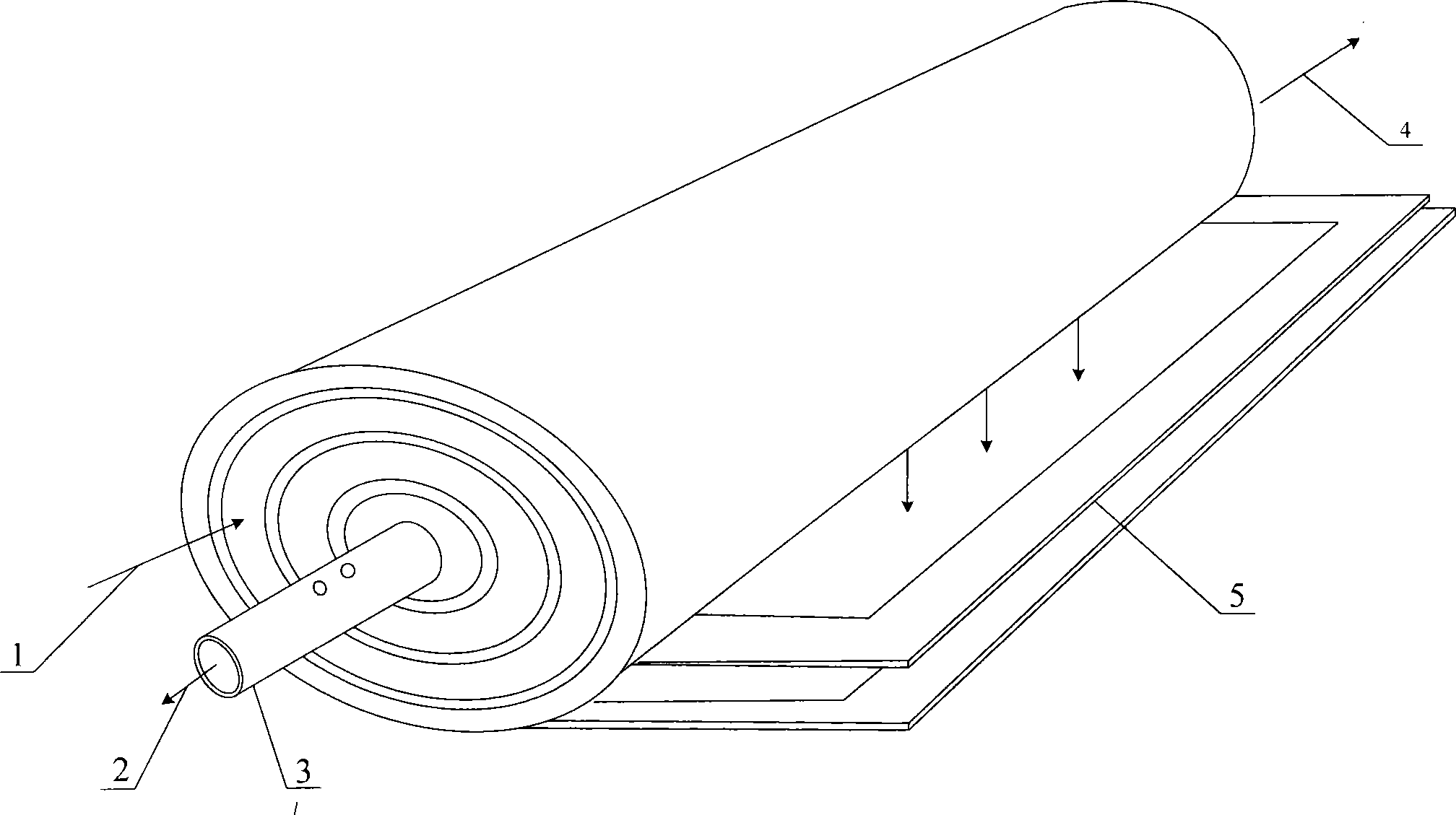

[0041] The raw material is catalytic liquefied petroleum gas containing 40ppm hydrogen sulfide sulfur, 300ppm mercaptan sulfur, and 30ppm carbonyl sulfide sulfur. It enters the membrane device through the raw material pump at an operating pressure of 0.8 MPa (MPa) and an operating temperature of 30°C. Separation of the composite membrane composed of polyvinylidene fluoride base membrane and polyhydroxyl-terminated polybutadiene-acrylonitrile membrane of the spiral membrane device, 99.09% of refined liquefied petroleum gas is obtained on the retentate side of the membrane device, and the content of hydrogen sulfide and sulfur 1ppm, mercaptan sulfur content 6ppm, carbonyl sulfide sulfur 1ppm; get 0.91% sulfide-rich liquefied petroleum gas on the permeation side of the membrane device, hydrogen sulfide content 4308ppm, mercaptan sulfur content 32313ppm, carbonyl sulfide sulfur 3220ppm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com