Method for preparing pH-responsive carbon nanotube fluorescent probe

A carbon nanotube and fluorescent probe technology is applied in the preparation field of the nanomaterial technology field, and achieves the effects of strong controllability, good water solubility, and a simple and easy preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

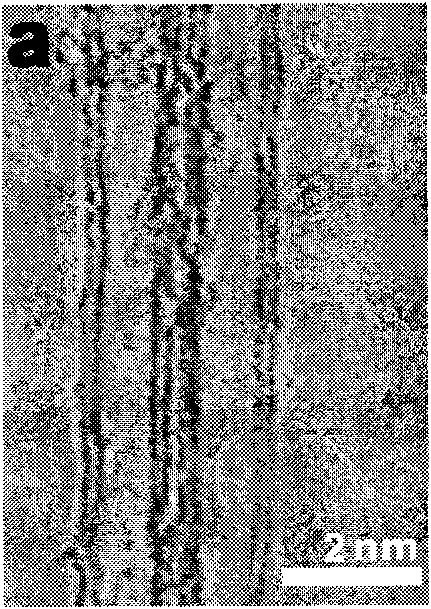

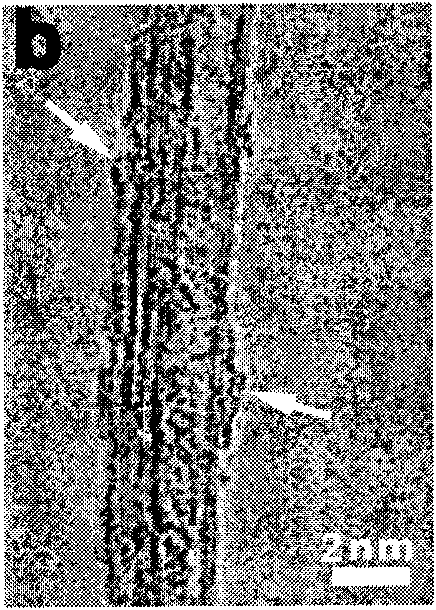

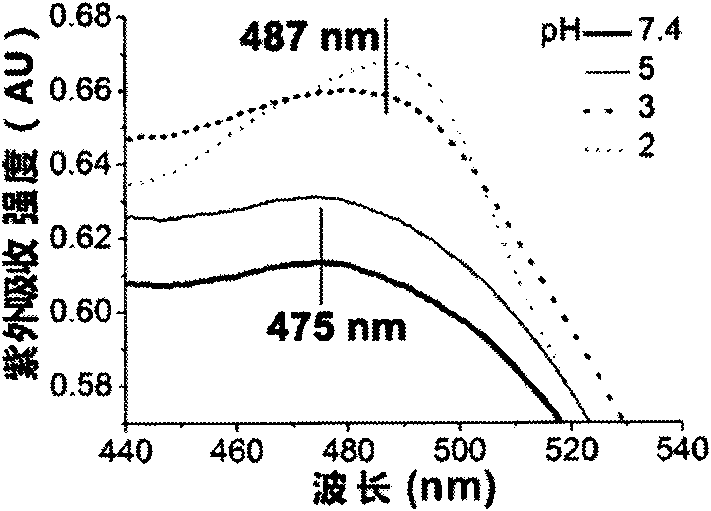

[0029] Example 1. The single-walled carbon nanotubes prepared by the chemical vapor deposition method are used as the initial raw material. After purification and truncation, acridine orange is adsorbed to the surface of the single-walled carbon nanotubes through non-covalent physical action, and the pH response is obtained. A single-walled carbon nanotube fluorescent probe specifically comprises the following steps:

[0030] Step (a): In a single-necked round-bottomed flask equipped with a magnetic stirring rotor, add 1 g of single-walled carbon nanotube raw material and 4 mol / L nitric acid, treat with 40 kHz ultrasonic waves for 20 min, heat to 95 ° C, stir and reflux React for 12 hours, filter with ф0.22 μm polytetrafluoroethylene microporous membrane, wash repeatedly with a large amount of deionized water until the pH value is 7 to neutral, and dry in vacuum at 50°C for 24 hours to obtain purified carbon nanotubes;

[0031] Step (b): In 300 mL of 98% H with a volume ratio ...

Embodiment 2

[0035] Example 2, using the single-walled carbon nanotubes prepared by catalytic pyrolysis as the initial raw material, after being purified and truncated, acridine orange is adsorbed to the surface of the single-walled carbon nanotubes through non-covalent physical action to obtain a pH-responsive A single-walled carbon nanotube fluorescent probe specifically comprises the following steps:

[0036] Step (a): In a single-necked round-bottomed flask equipped with a magnetic stirring rotor, add 20 mg of single-walled carbon nanotube raw material and 20% sulfuric acid, heat it to 110 ° C after 40 kHz ultrasonic treatment for 15 min, stir and reflux 24h, filter with ф0.22μm polytetrafluoroethylene microporous membrane, wash repeatedly with a large amount of deionized water until the pH value is 7 to neutral, and vacuum dry at 50°C for 24h to obtain purified carbon nanotubes;

[0037] Step (b): In 300 mL of 98% H with a volume ratio of 3:1 2SO 4 and 65% HNO 3 Add 500 mg of the p...

Embodiment 3

[0040] Example 3: Using multi-walled carbon nanotubes prepared by chemical vapor deposition as the initial raw material, after purification and truncation, acridine orange is adsorbed to the surface of multi-walled carbon nanotubes through non-covalent physical action to obtain pH responsiveness Multi-walled carbon nanotube fluorescent probe.

[0041] Step (a): In a single-neck round bottom flask equipped with a magnetic stirring rotor, add 40 mg of multi-walled carbon nanotube raw material and 2.6 mol / L nitric acid, treat with 40 kHz ultrasonic wave for 30 min, heat to 120 ° C, stir and reflux After reacting for 48 hours, filter with ф0.22 μm polytetrafluoroethylene microporous membrane, wash repeatedly with a large amount of deionized water until the pH value is 7 to neutral, and vacuum dry at 50°C for 24 hours to obtain purified carbon nanotubes;

[0042] Step (b): In 300 mL of 98% H with a volume ratio of 3:1 2 SO 4 and 65% HNO 3 Add 500 mg of the purified carbon nanotu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com