Fiber coupling method for diode pumping solid-state laser

A solid-state laser, fiber coupling technology, applied in lasers, laser parts, laser parts, etc., can solve the problem of reducing the numerical aperture and effective clear aperture of the coupling lens, increasing the complexity of the adjustment structure, and difficult to achieve high coupling efficiency, etc. problems, to achieve the effect of simplifying the structure, reducing requirements, and simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Diode-pumped solid-state lasers have the characteristics of compact structure, high reliability, and good beam quality. For rod-shaped crystals, the usual pumping methods are divided into end pumping and side pumping.

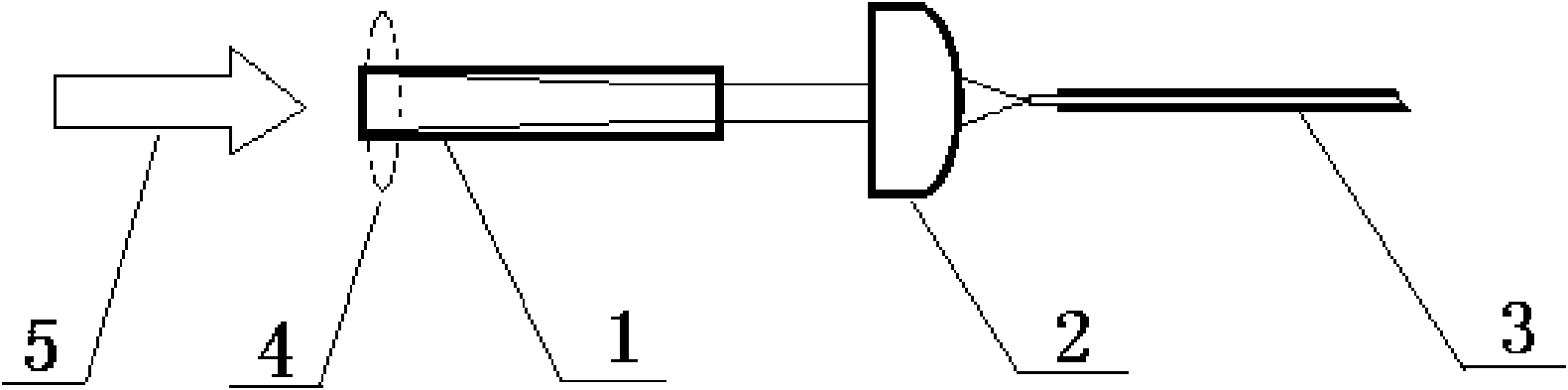

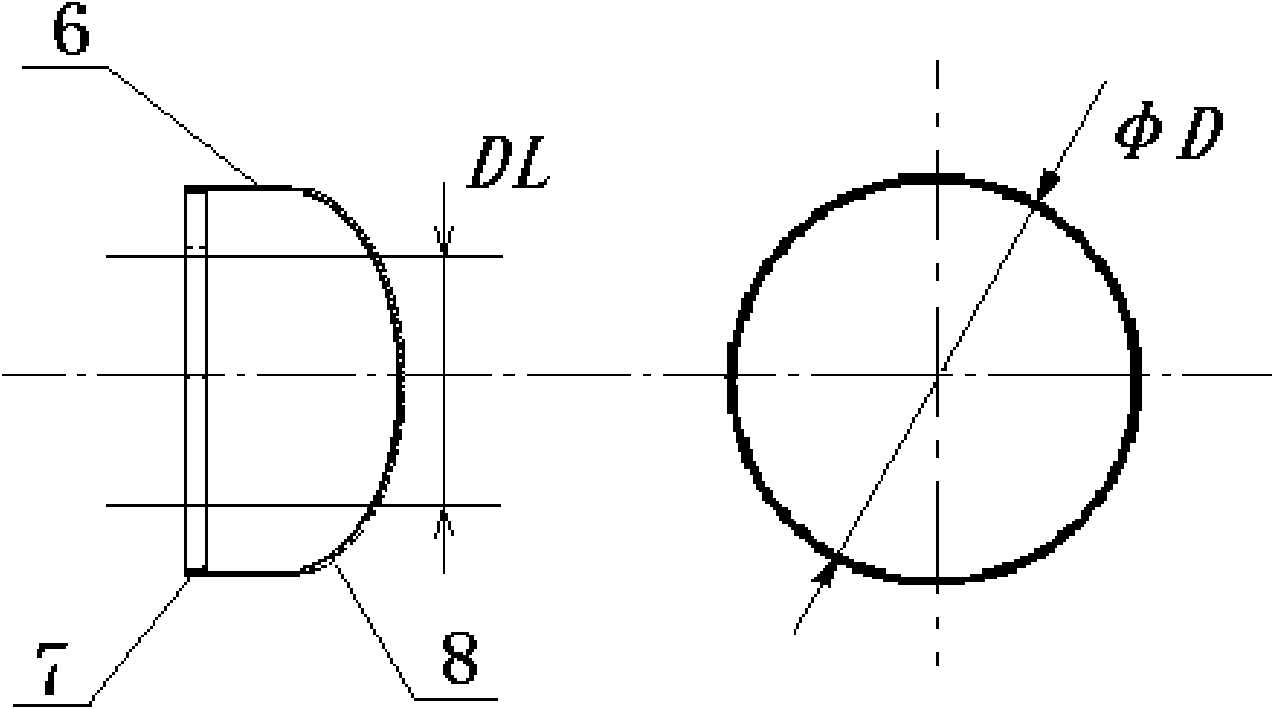

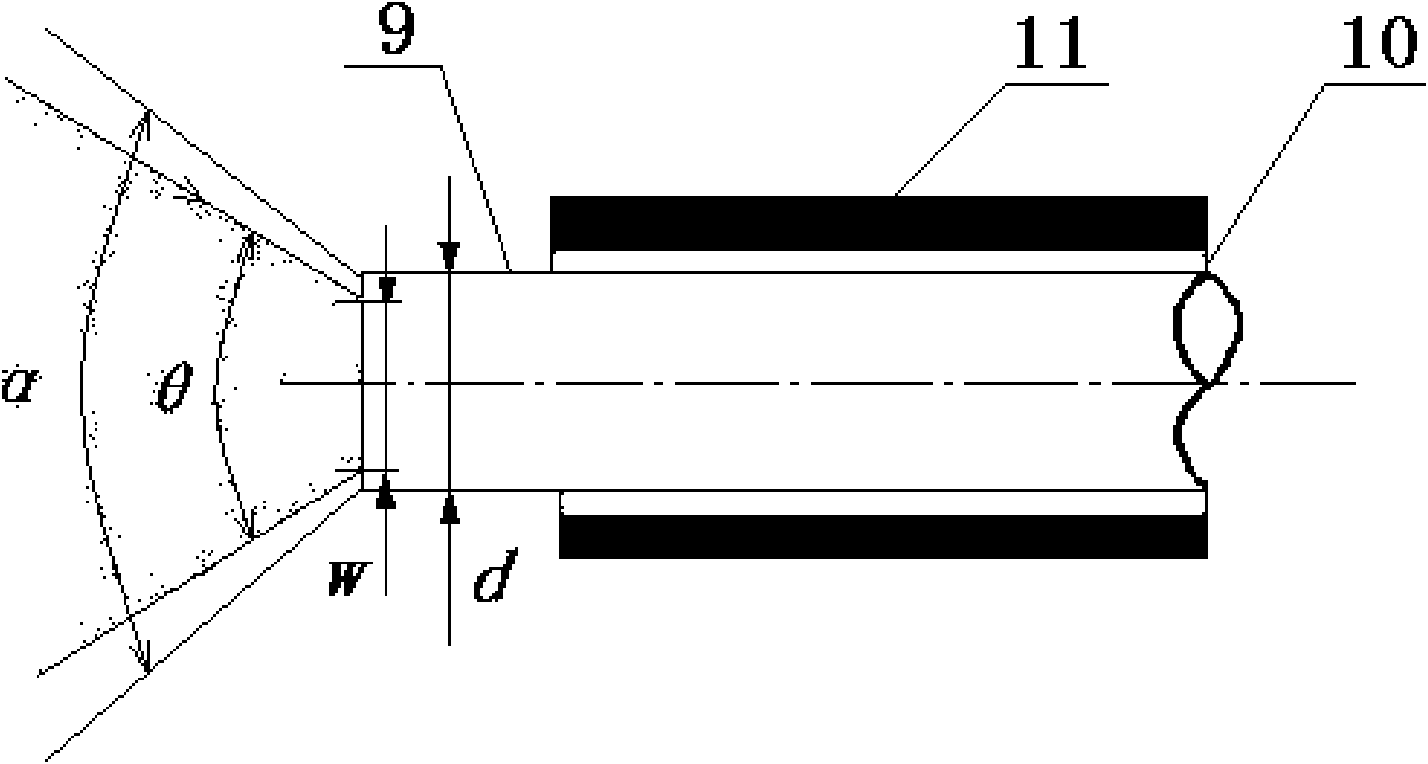

[0025] figure 1 Given the end-pumping method, the pumping light is 5 to the laser crystal 1 (such as Nd:YAG, Nd:YVO 4 The end surface of the laser crystal 1 is usually coated with a pump light anti-reflection and oscillating light high-reflective coating (such as AR@808nm / HR@1064nm), which is used as a total reflection mirror of the resonant cavity. Usually a flat mirror is used as the output mirror. At this time, the resonant cavity is a flat-flat cavity, which is a metastable cavity. When the laser is working, the end face of the laser crystal 1 will produce a strong thermal effect. It can be equivalent to the thermal lens 4 at the end face. It is precisely because of the existence of the thermal lens 4 that the resonant cavity becomes a stable cavity. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Focal length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com