Method for preparing three-dimensional silk fibroin porous scaffold material

A technology of porous scaffolds and three-dimensional silk fibroin, applied in medical science, prosthesis, etc., can solve the problems of tediousness, toxicity of scaffolds, inability to effectively prepare porous silk fibroin scaffolds, etc., and achieve the effect of reducing costs and simplifying process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

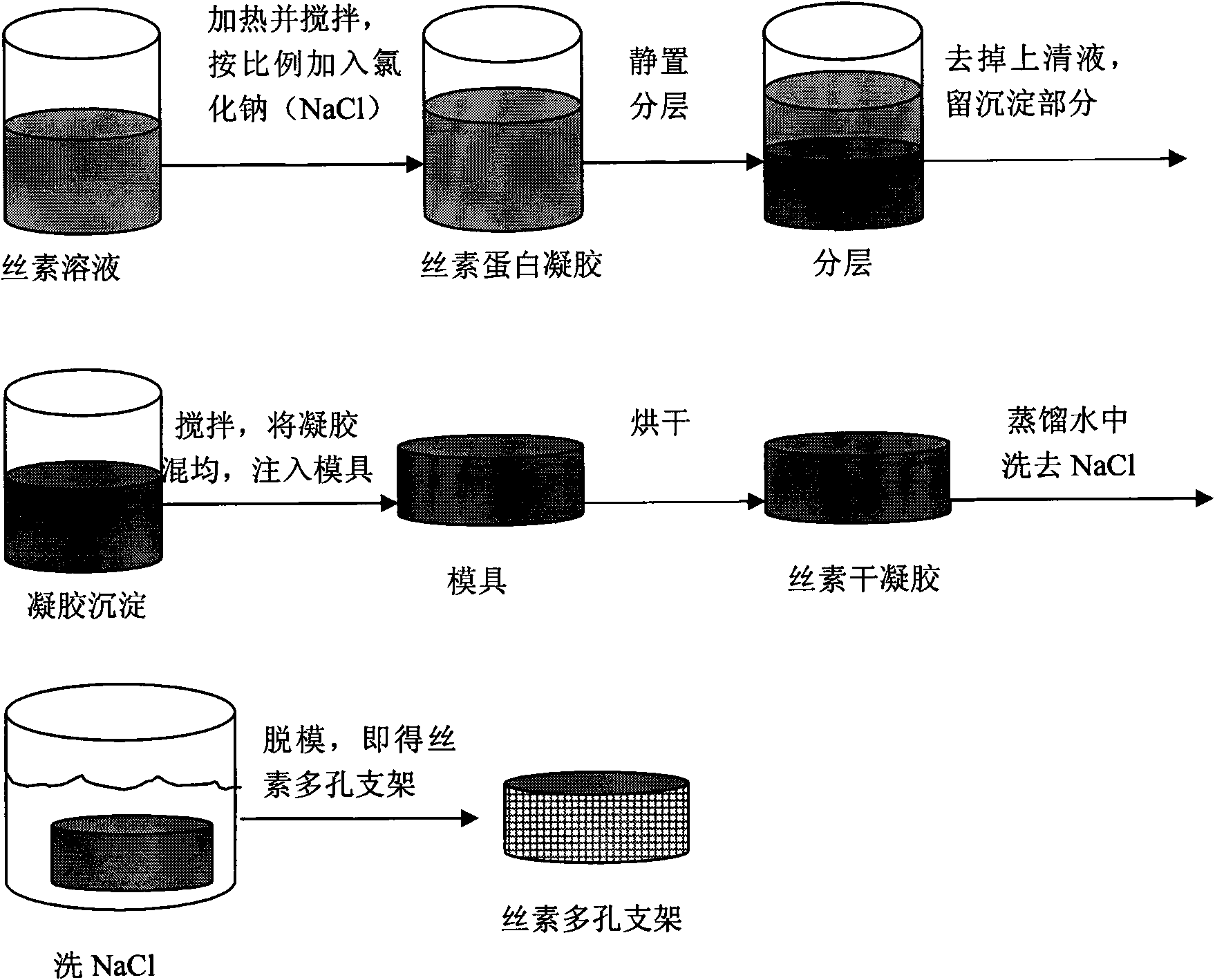

Embodiment 1

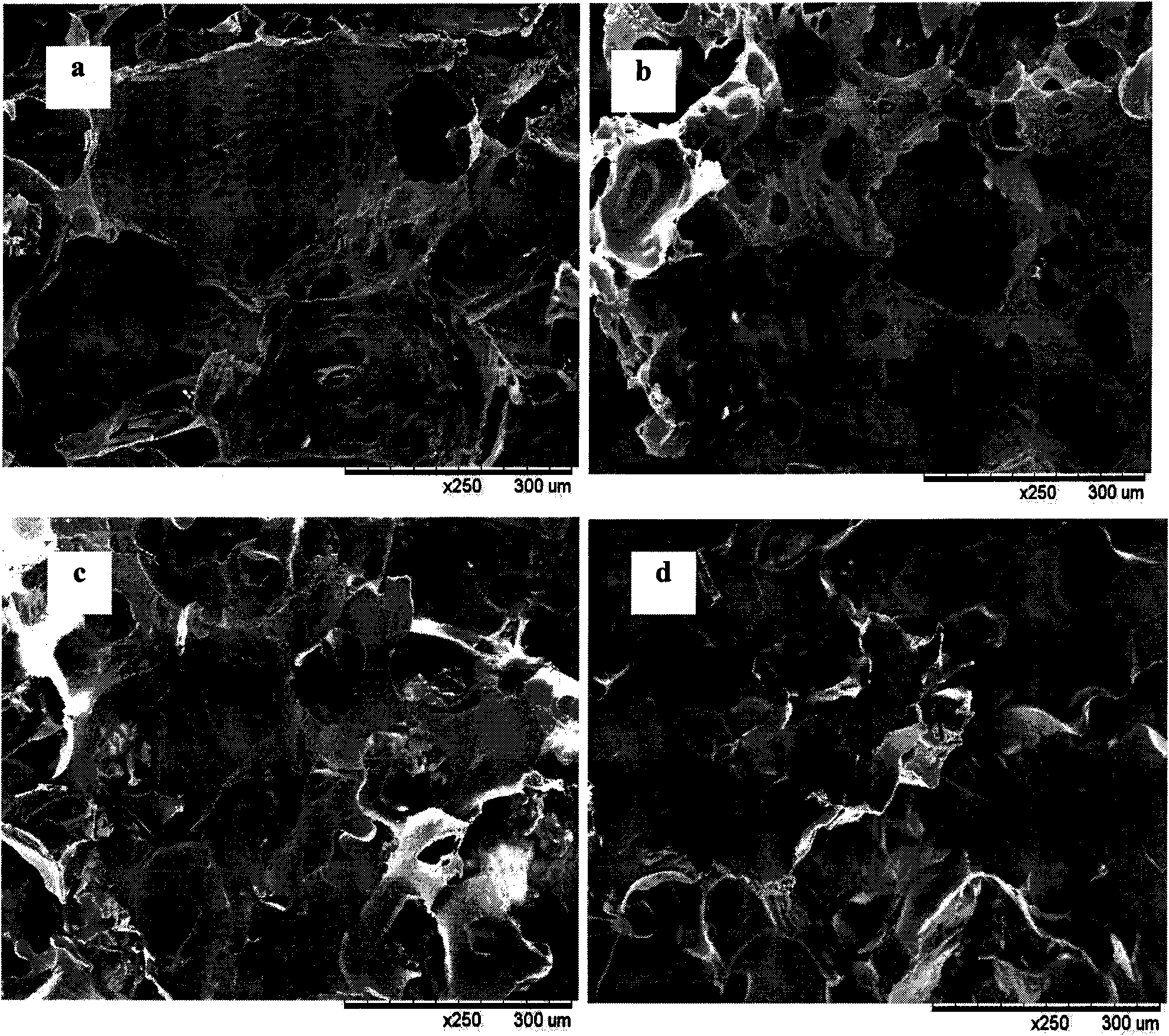

[0028] Sodium chloride is passed through a 200-mesh sieve. Heat 20ml of silk fibroin solution with a concentration of 2wt% to 60°C, and add 20g of sodium chloride while stirring gently. After the silk fibroin solution is gelled, let it stand to make the silk fibroin gel precipitate completely, remove the supernatant liquid, and leave the precipitated part. Continue to stir to mix the sediment evenly, then put the sediment into a mold and dry it. Immerse the dried sample together with the container into distilled water until the sodium chloride in the frame is completely dissolved, and finally obtain a three-dimensional silk fibroin porous frame material with a porosity of 98.1%.

Embodiment 2

[0030] Repeat the method of Example 1, wherein the volume of silk fibroin solution is 40ml, the quality of sodium chloride is 20g, the finally obtained three-dimensional silk fibroin porous scaffold material has a porosity of 99.3%.

Embodiment 3

[0032] Repeat the method of Example 1, wherein the concentration of silk fibroin solution is 50wt%, the volume is 100ml, and the mass of sodium chloride is 10g. The porosity of the finally obtained three-dimensional silk fibroin porous scaffold material is 69.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com