Method for preparing mono-disperse loose porous acrylonitrile/methyl acrylate copolymer microspheres

A methyl acrylate, loose and porous technology, which is applied in the preparation of acrylonitrile/methyl acrylate copolymer microspheres and the preparation of monodisperse loose porous microspheres, achieving the effect of simple and easy preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] Add 0.012 grams of polyvinyl alcohol, 2.5 milliliters of Span 80, 32.2 grams of acrylonitrile, 7.6 grams of methyl acrylate, and 0.11 grams of potassium persulfate into 16 milliliters of deionized water, raise the temperature to 68 degrees Celsius, adjust the stirring rate to 400 rpm, and suspend State emulsion polymerization, reacted for 2 hours, the product was cooled, separated, extracted by Soxhlet extractor for 24 hours, and dried in vacuum to obtain monodisperse porous acrylonitrile / methyl acrylate copolymer microspheres.

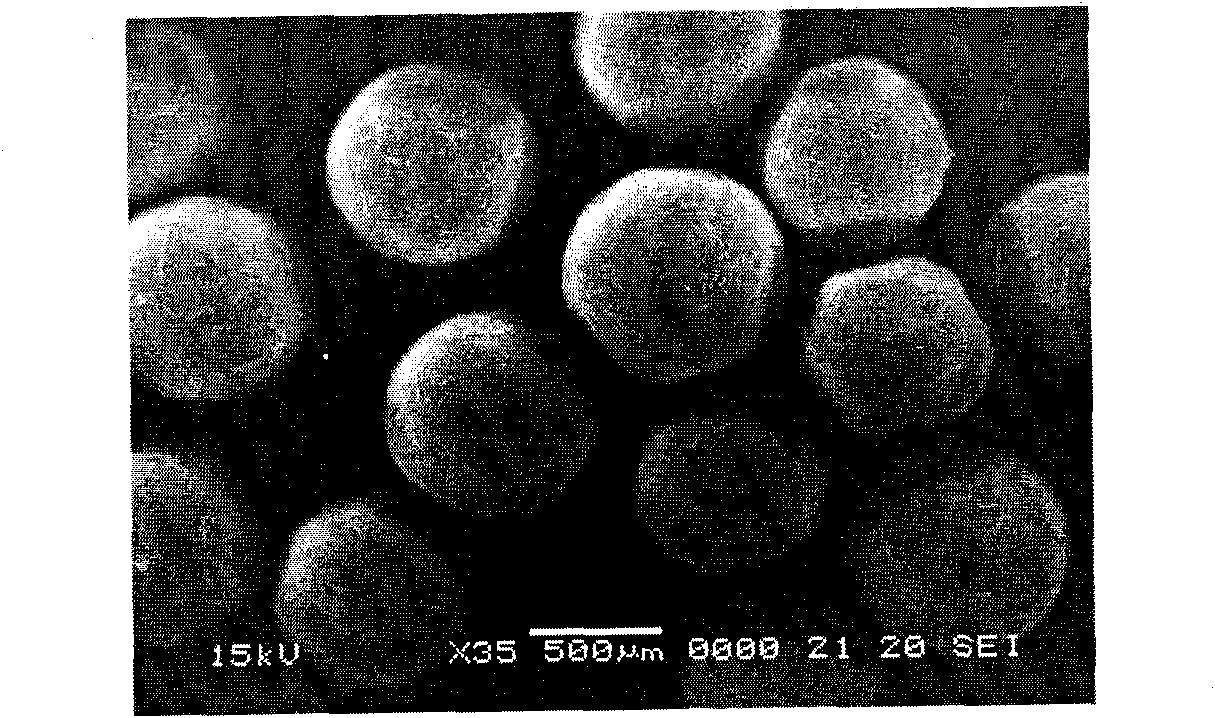

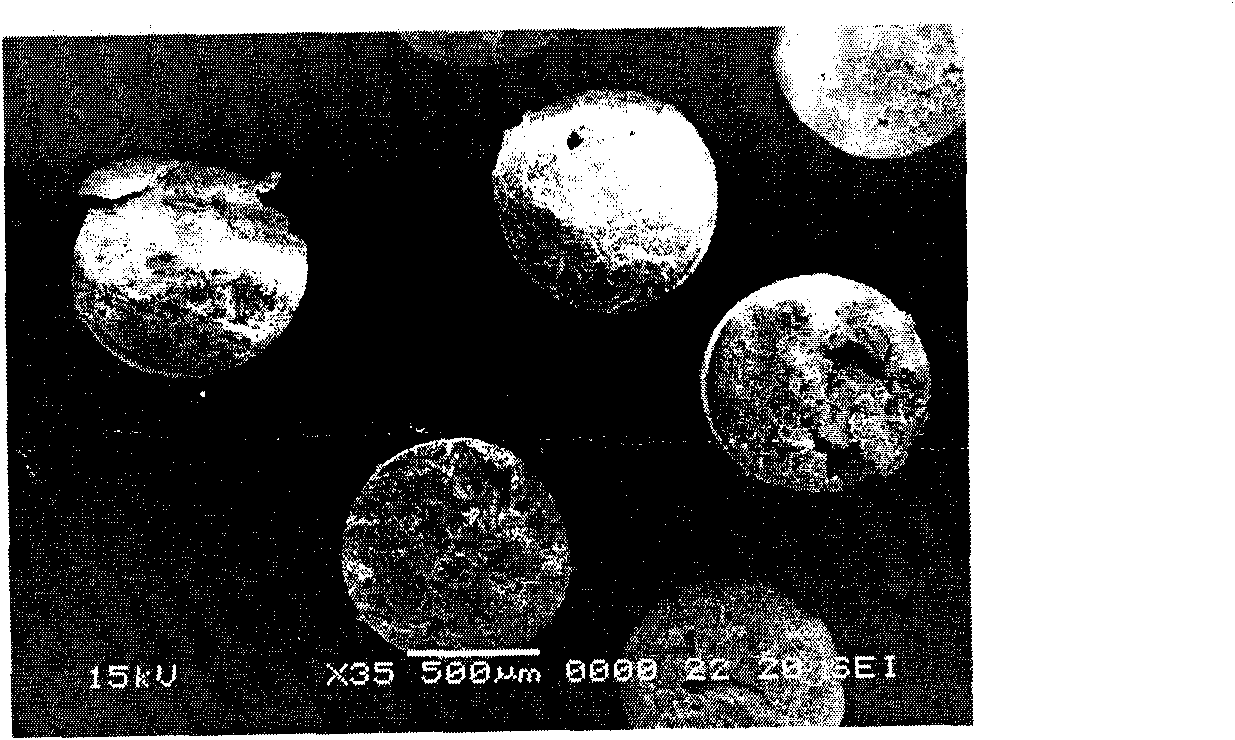

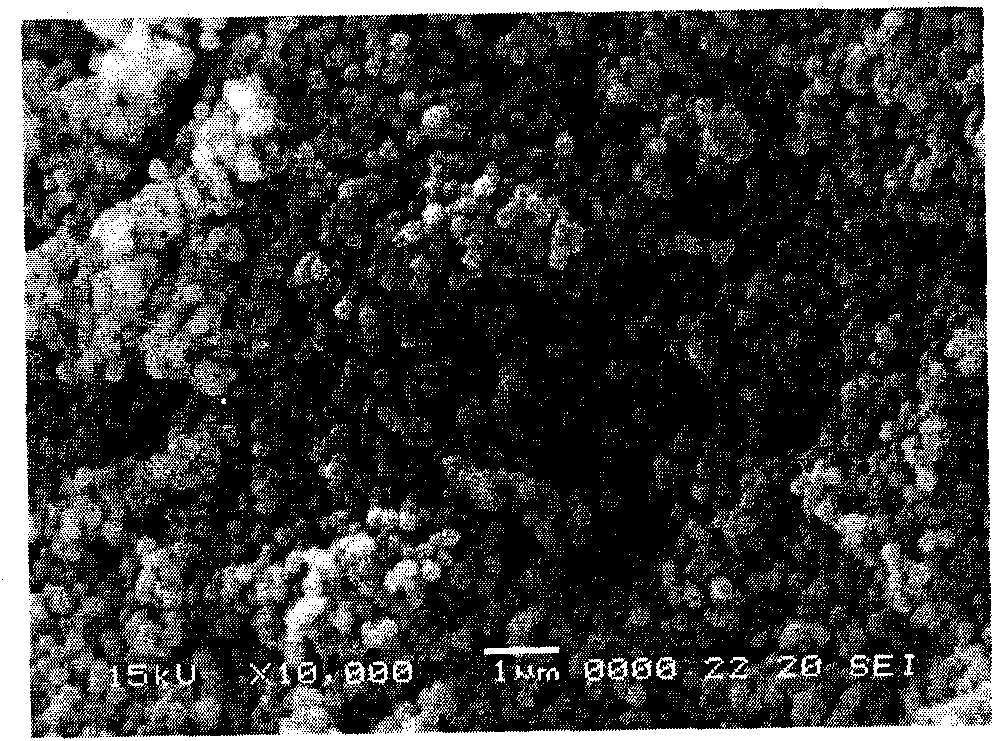

[0013] The average particle diameter of the obtained copolymer microspheres was 921.6 microns. Scanning electron micrographs of the microspheres and their anatomical surfaces and interiors are shown in figure 1 , figure 2 and image 3 shown.

Embodiment 2

[0015] Add 0.014 grams of polyvinyl alcohol, 2.5 milliliters of Span 80, 24.2 grams of acrylonitrile, 5.7 grams of methyl acrylate, and 0.24 grams of potassium persulfate into 18 milliliters of deionized water, raise the temperature to 62 degrees Celsius, adjust the stirring rate to 500 rpm, and suspend State emulsion polymerization, reacted for 4 hours, the product was cooled, separated, extracted by Soxhlet extractor for 24 hours, and dried in vacuum to obtain monodisperse porous acrylonitrile / methyl acrylate copolymer microspheres.

[0016] The obtained copolymer microspheres had an average particle diameter of 455.2 microns, good monodispersity and loose porosity.

Embodiment 3

[0018] Add 0.016 grams of polyvinyl alcohol, 2.5 milliliters of Span 80, 32.2 grams of acrylonitrile, 7.6 grams of methyl acrylate, and 0.11 grams of potassium persulfate into 16 milliliters of deionized water, raise the temperature to 68 degrees Celsius, adjust the stirring rate to 600 rpm, and suspend State emulsion polymerization, reacted for 2 hours, the product was cooled, separated, extracted by Soxhlet extractor for 24 hours, and dried in vacuum to obtain monodisperse porous acrylonitrile / methyl acrylate copolymer microspheres.

[0019] The average particle diameter of the obtained copolymer microspheres is 350.6 microns, and the monodispersity and loose porosity are good.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com