Preparation method of potato aspartic proteinase inhibitor

A protease inhibitor, aspartic acid technology, applied in the direction of protease inhibitors, peptide preparation methods, chemical instruments and methods, etc., can solve problems such as high pollution, achieve pollution elimination, prevent resource waste, and easy operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

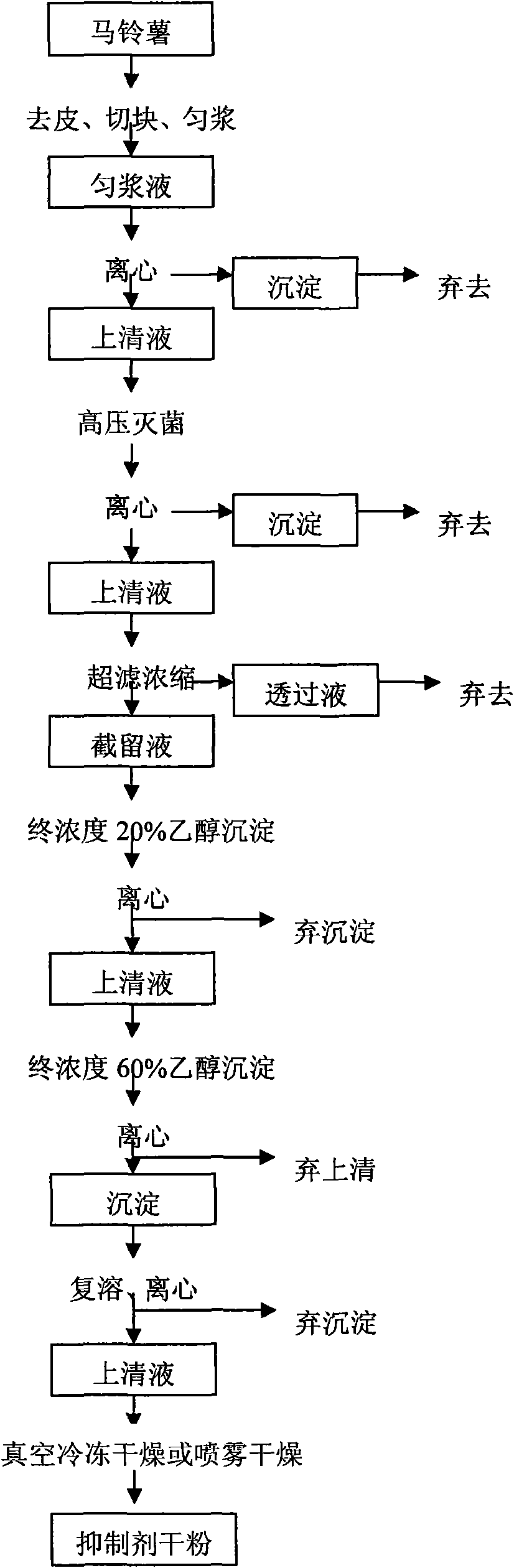

Method used

Image

Examples

Embodiment 1

[0028] Example 1: After 682.7g potatoes are washed, peeled and cut into pieces, press 0.5g Na 2 SO 3 Add 0.341g Na / kg potato 2 SO 3 To prevent polyphenol oxidation, after homogenization, centrifuge at 8000r / min, 4°C for 30min to obtain 510mL supernatant, autoclave the supernatant at 121°C for 20min, cool to room temperature, centrifuge at 14000r / min, 4°C for 20mim, The precipitate was discarded, and the collected 432mL supernatant was concentrated with a 10KDa ultrafiltration membrane, and ultrafiltered at a pressure of 0.075MPa and room temperature for 10min to obtain a concentrated solution of 112mL, with an inhibitory rate of about 5.19U / mg to pepsin, protein and sugar The concentration ratio is about 1.47, and the yield is about 86.1%. Add 28mL-20°C ethanol to the concentrate, centrifuge at 10000r / min and 4°C for 10min, take the supernatant and add 160.5mL-20°C ethanol, 10000r / min , After centrifuging at 4°C for 10 minutes, take the precipitate; add 40 mL of pH 6.8 phos...

Embodiment 2

[0029] Embodiment 2: After 887.6g potatoes are washed, peeled and cut into pieces, press 0.5g Na 2 SO 3 Add 0.443g Na / kg potato 2 SO 3To prevent polyphenol oxidation, after homogenization, centrifuge at 8000r / min, 4°C for 30min to obtain 562mL supernatant, autoclave the supernatant at 121°C for 20min, cool to room temperature, centrifuge at 14000r / min, 4°C for 20mim, The precipitate was discarded, and the collected 480mL supernatant was concentrated with a 10KDa ultrafiltration membrane, and ultrafiltered at a pressure of 0.075MPa and room temperature for 10min to obtain a concentrated solution of 95mL with an inhibitory rate of about 4.65U / mg to pepsin. The concentration ratio is about 1.23, and the yield is about 84.6%. Add 23.75mL-20°C ethanol to the concentrate, centrifuge at 10000r / min and 4°C for 10min, take the supernatant and add 142.5mL-20°C ethanol, 10000r / min After centrifuging for 10 min at 4°C for 10 min, take the precipitate; add 40 mL of pH 6.8 phosphate buff...

Embodiment 3

[0030] Embodiment 3: After 507.3g potatoes are washed, peeled and cut into pieces, press 0.5g Na 2 SO 3 Add 0.254g Na / kg potato 2 SO 3 To prevent polyphenol oxidation, after homogenization, centrifuge at 8000r / min, 4°C for 30min to obtain 321mL supernatant, autoclave the supernatant at 121°C for 20min, cool to room temperature, centrifuge at 14000r / min, 4°C for 20mim, The precipitate was discarded, and the collected 250mL supernatant was concentrated with a 10KDa ultrafiltration membrane, and ultrafiltered at a pressure of 0.075MPa and room temperature for 10min to obtain a concentrated solution of 87mL, with a specific inhibitory activity to pepsin of about 3.98U / mg. The concentration ratio of sugar is about 1.36, and the yield is about 81.9%. Add 21.75mL-20°C ethanol to the concentrate, centrifuge at 10000r / min and 4°C for 10min, take the supernatant and add 130.5mL-20°C ethanol, 10000r After centrifugation at 10000r / min and 4°C for 10 minutes, take the precipitate; add 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com