Process for recovering liquefied petroleum gas from dry distillation tail gas of oil shale

A liquefied petroleum gas and tail gas recovery technology, which is applied in the petroleum industry, special dry distillation, gas fuel, etc., can solve problems such as pollution and shale semi-coke utilization, and achieve good economic benefits, increase added value, and reduce production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

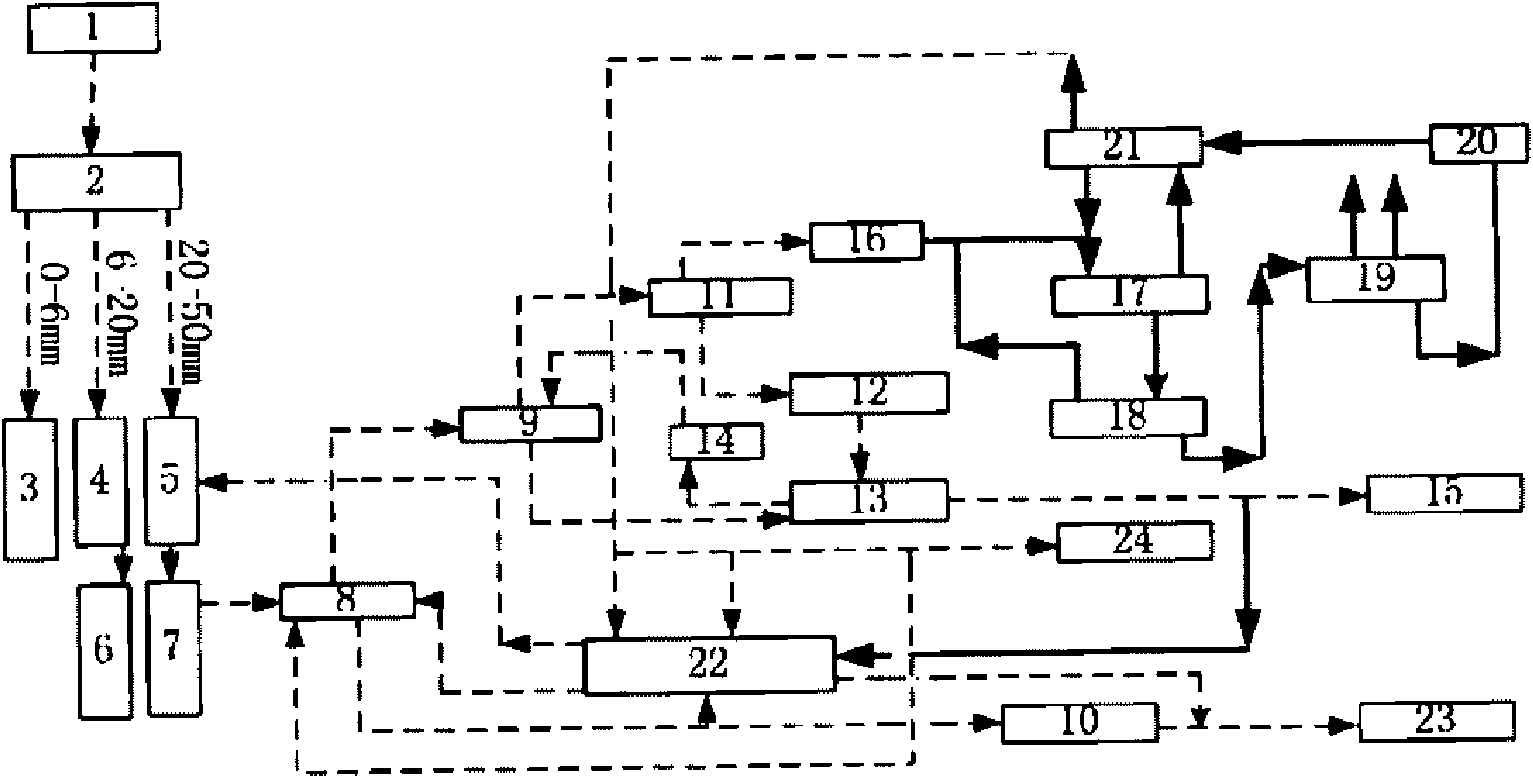

[0017] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

[0018] The specific implementation of the present invention is to fully recover and extract C3 and heavy components above C3 in the dry distillation tail gas to obtain LPG and naphtha products under the premise of ensuring sufficient heat supply to the heating furnace. For this reason, the technical process of compression unit 20, absorption unit 21, pre-desorption unit 18, and desorption unit 19 is designed. The dry distillation tail gas at 80°C is pressurized into the dry distillation tail gas cabinet 16 to be buffered and stabilized, and then mixed with the enriched gas from the absorption unit 21. The absorption oil and the pre-desorption gas from the pre-desorption unit 18 are mixed, and enter the condensed oil tank 17 after being cooled. The condensed oil enters the tower from the top of the pre-desorption towe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com