2,2'-dichlorohydrazobenzene preparation method and special electrolytic tank thereof

A dichlorohydrogen azo, electrolytic cell technology, applied in 2 fields, can solve the problems of poor proton permeability, increase production cost, increase power consumption, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Step A Activate Porous Cathode Plate and Porous Anode Plate

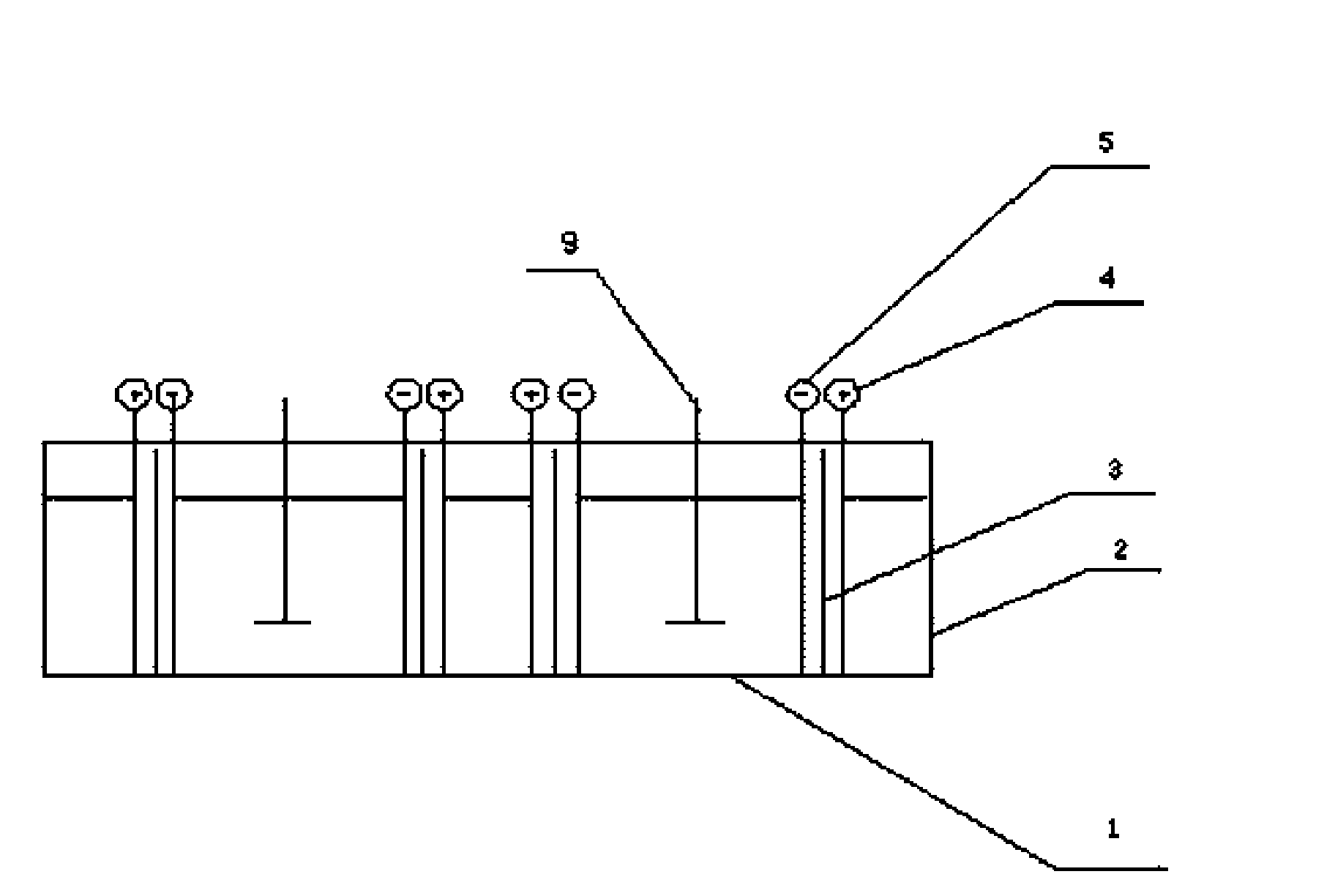

[0038] Pour 4550ml of cathodic lye NaOH solution with a concentration of 5wt% into cathode tank 1, and pour 7000ml of anolyte lye NaOH solution with a concentration of 30wt% into anode tank 2. Preheat the cathode lye in the cathode tank 1 at 50°C for 30 minutes, and at the same time pass the current density of 1A / dm 2 The current activates the porous cathode plate 5 and the porous anode plate 4, and the activation time is the same as the preheating time;

[0039] Preparation of 2,2'-dichlorohydroazobenzene by electrolytic reduction in step B

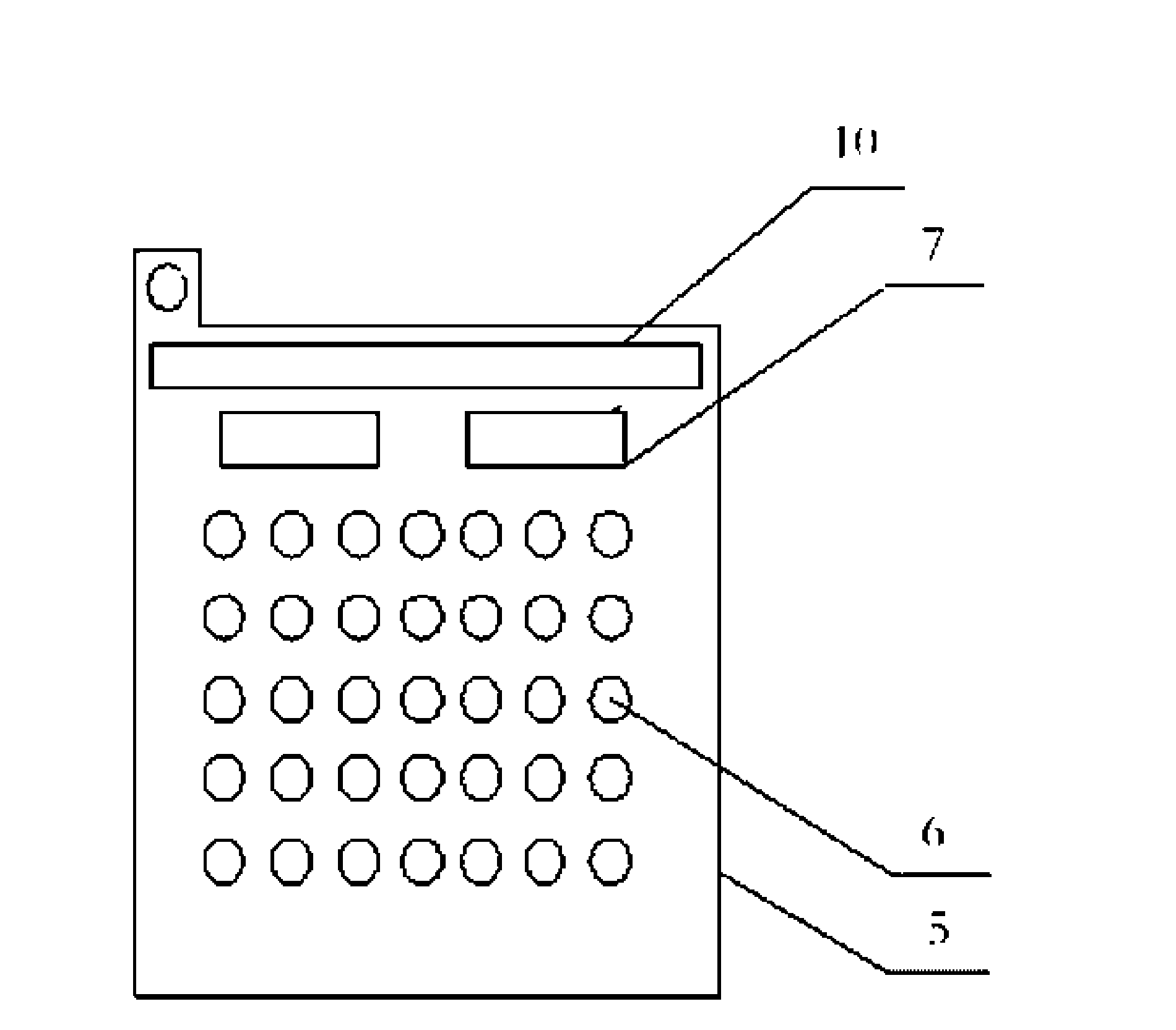

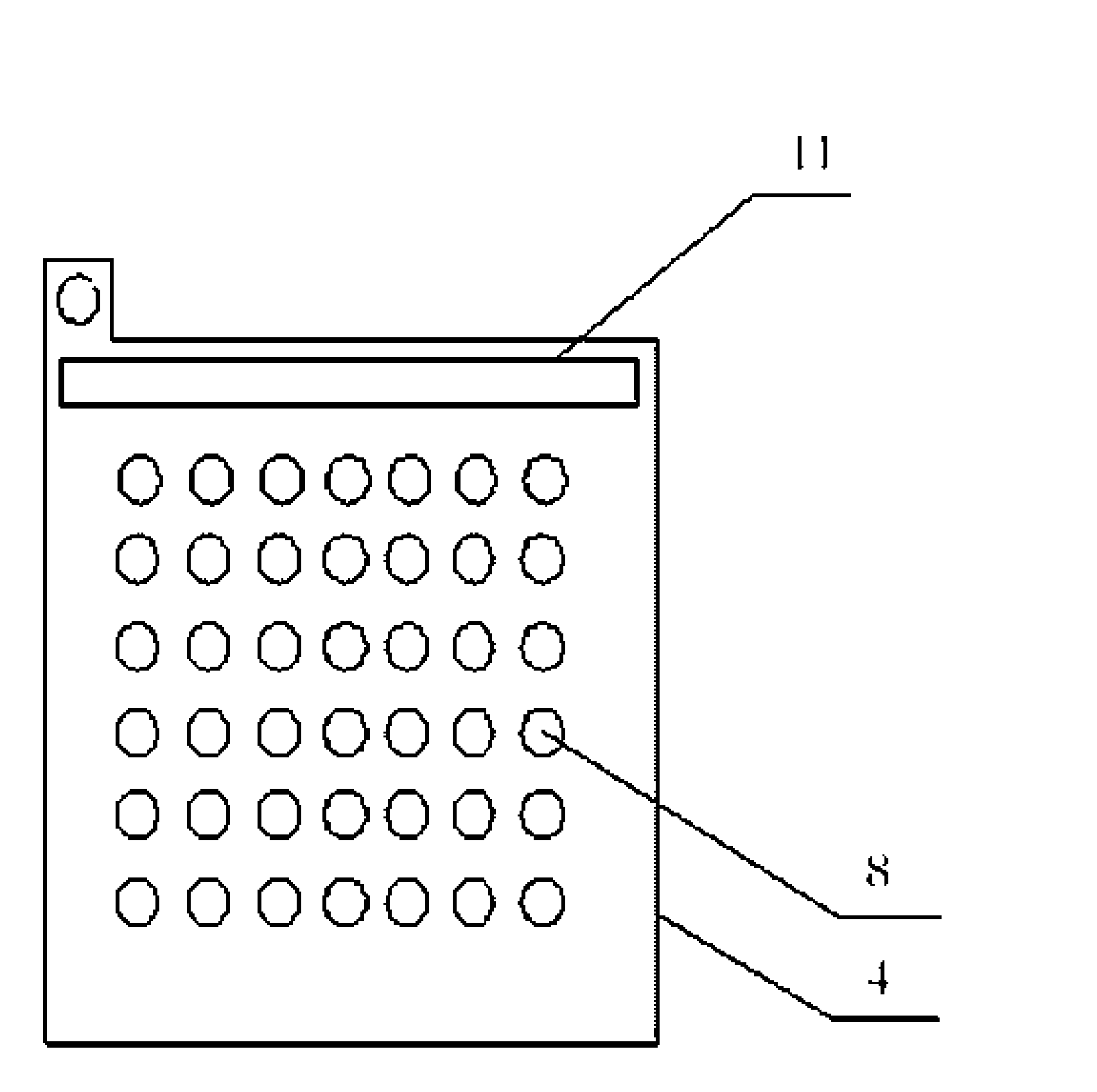

[0040] Add 450g of o-chloronitrobenzene, 1500ml of toluene, and 3.5g of cocatalyst sodium dodecylbenzenesulfonate into the cathode tank 1 in sequence, start the stirrer 9, and after the solution is mixed evenly, the porous anode plate 4 and the power supply anode Connection, the porous cathode plate 5 is connected to the cathode of the power supply, the hole 6 on the ...

Embodiment 2

[0046] Step A Activate Porous Cathode Plate and Porous Anode Plate

[0047]Pour 4550ml of cathodic lye KOH solution with a concentration of 10wt% into the cathode tank 1, and pour 7000ml of anolyte lye KOH solution with a concentration of 20wt% into the anode tank 2. Preheat the cathode lye in the cathode tank 1 at 60°C for 15 minutes, and at the same time pass the current density to 1.5A / dm 2 The current activates the porous cathode plate 5 and the porous anode plate 4, and the activation time is the same as the preheating time.

[0048] Preparation of 2,2'-dichlorohydroazobenzene by electrolytic reduction in step B

[0049] Add 450g of o-chloronitrobenzene, 1500ml of xylene, and 3.5g of cocatalyst sodium dodecylbenzenesulfonate into the cathode tank 1 in turn, start the stirrer 9, and after the solution is mixed evenly, the porous anode plate 4 and the power supply The anode is connected, the porous cathode plate 5 is connected to the cathode of the power supply, the hole ...

Embodiment 3

[0055] Step A Activate Porous Cathode Plate and Porous Anode Plate

[0056] Pour 4550ml of cathodic lye KOH solution with a concentration of 1wt% into cathode tank 1, and pour 7000ml of anode lye NaOH solution with a concentration of 40wt% into anode tank 2. Preheat the cathode lye in the cathode tank 1 at 30°C for 35 minutes, and at the same time pass the current density to 2.5A / dm 2 The current activates the porous cathode plate 5 and the porous anode plate 4, and the activation time is the same as the preheating time.

[0057] Preparation of 2,2'-dichlorohydroazobenzene by electrolytic reduction in step B

[0058] Add 450g of o-chloronitrobenzene, 1500ml of toluene, and 3.5g of cocatalyst sodium dodecylbenzenesulfonate into the cathode tank 1 in sequence, start the agitator 9, and after the solution is evenly mixed, the porous anode plate 4 and the power supply anode Connection, the porous cathode plate 5 is connected to the cathode of the power supply, the hole 6 on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com