Method for preparing magnetic material of rare-earth permanent magnet ferrite

A technology of permanent magnet ferrite and magnetic material, applied in the direction of inorganic material magnetism, etc., can solve the problems of high production cost of rare earth permanent ferrite, no consideration of additive synergy, and high price of pure compounds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

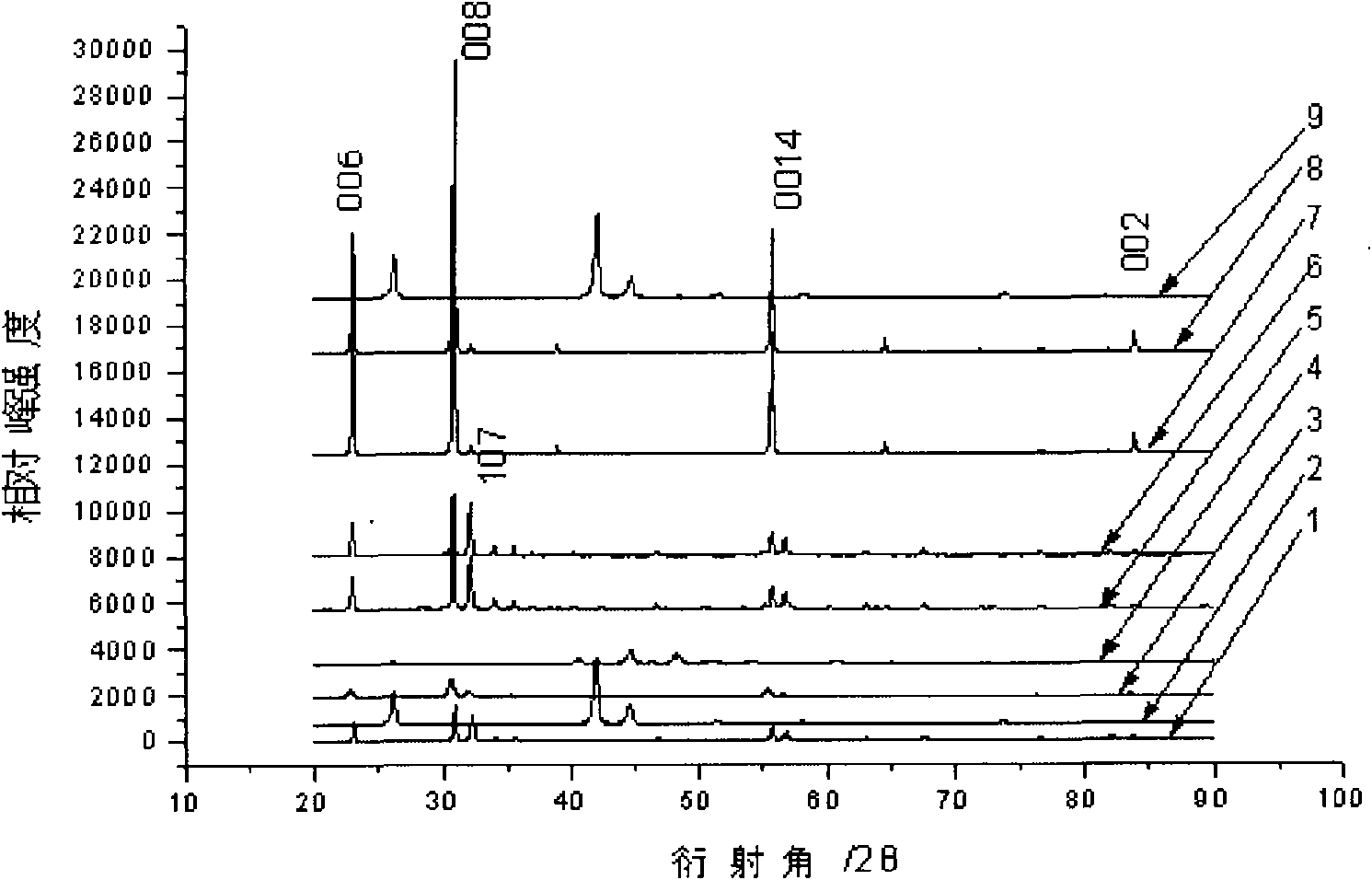

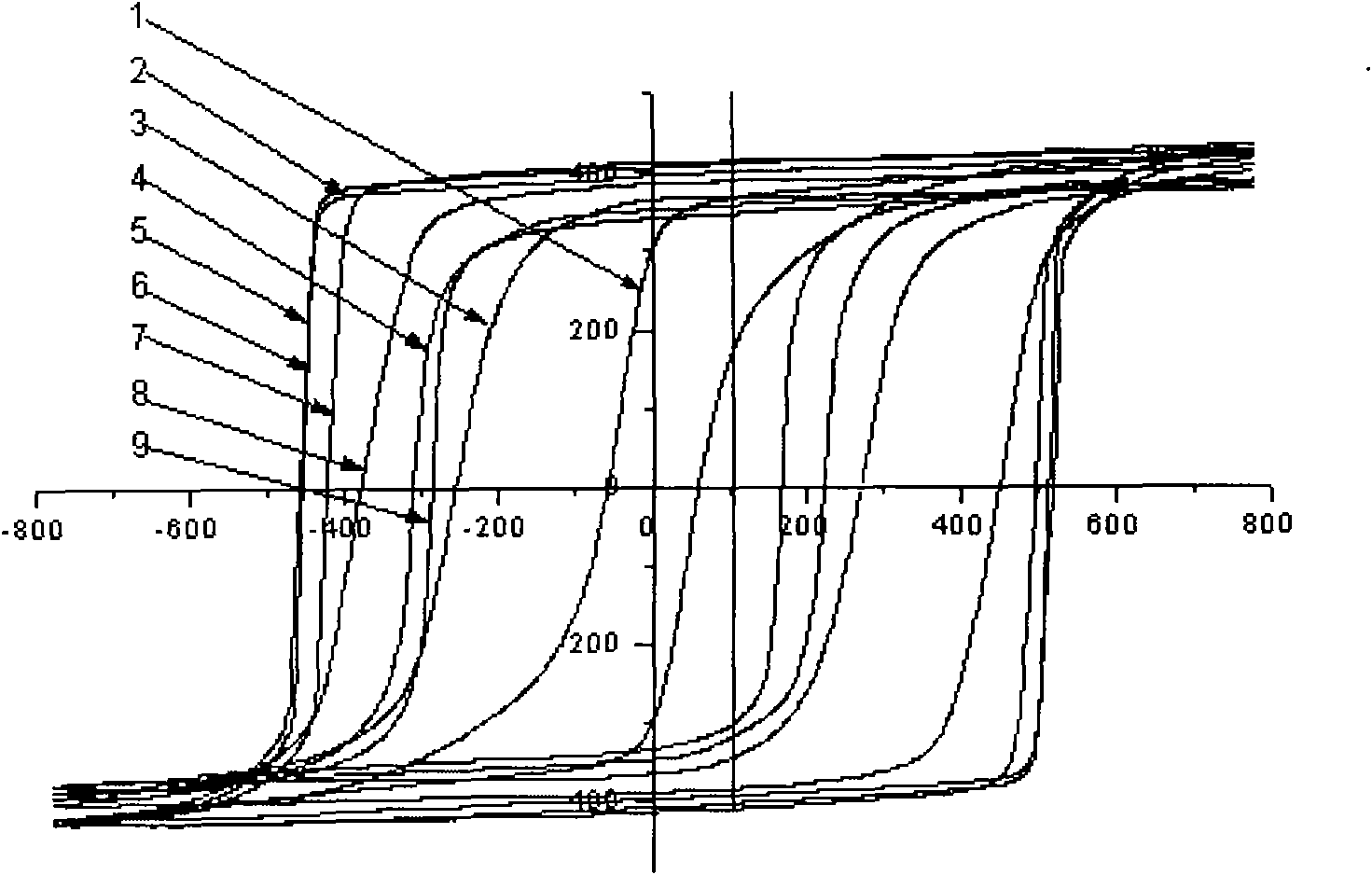

[0073] Below by accompanying drawing and embodiment the present invention is described in further detail, a kind of method for preparing high performance rare earth permanent magnet ferrite magnetic material, it comprises the following steps:

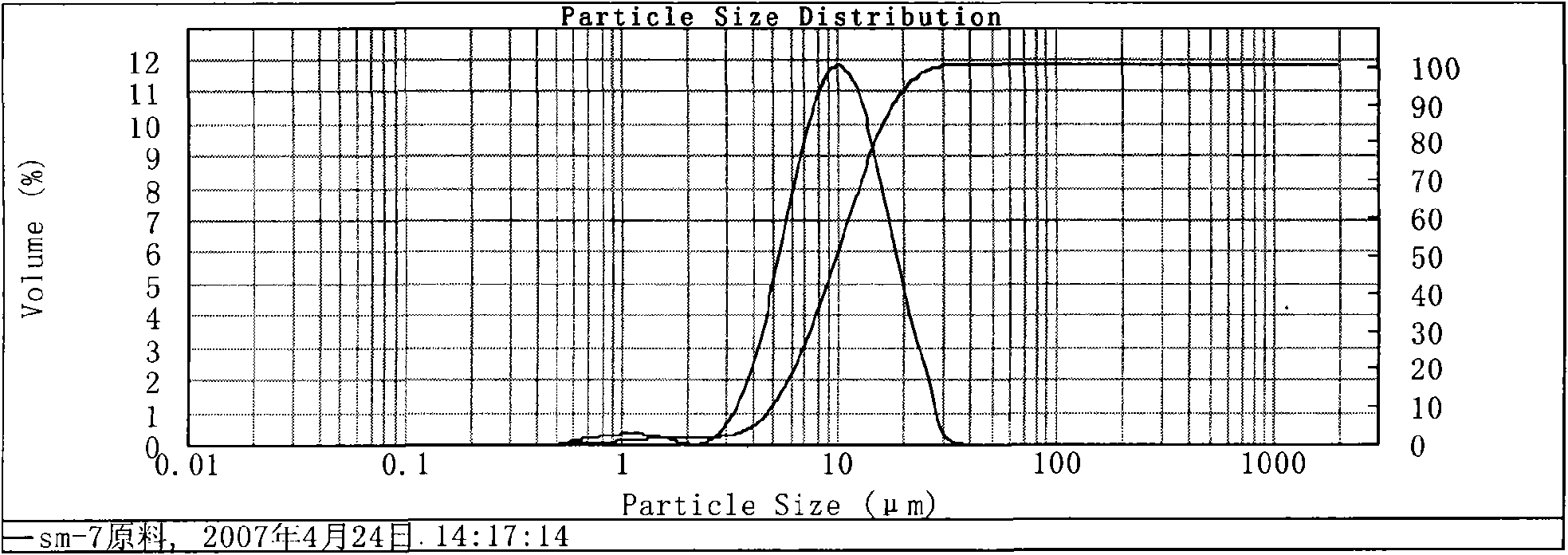

[0074] a: The calcined ferrite containing strontium or barium and the added additives are respectively added to the ball mill according to the mass formula ratio requirements, in which the calcined material is 85% to 95%, and the added additives are 5% to 15%. Then add a certain proportion of water, wherein the mass ratio of the total material to water is 1: (1.5-2.5) and the mass ratio of the steel ball to the total material is (4-8): 1 for ball milling and ultrafine pulverization, thus obtaining the average Aqueous slurry with a particle size distribution of 0.75-1.0 μm.

[0075] b: The slurry qualified by the above ball mill enters the sedimentation separation dehydration tank to separate the water statically. The slurry sinking time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com