Method for extracting pigment from walnut epicarp

A technology of walnut exocarp and extraction method, which is applied in the extraction of walnut exocarp pigment and in the field of plant extraction of natural pigment industry, which can solve the problems of destroying pigment components and extracting many impurities, and achieve high purity, high concentration efficiency, and easy recovery Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

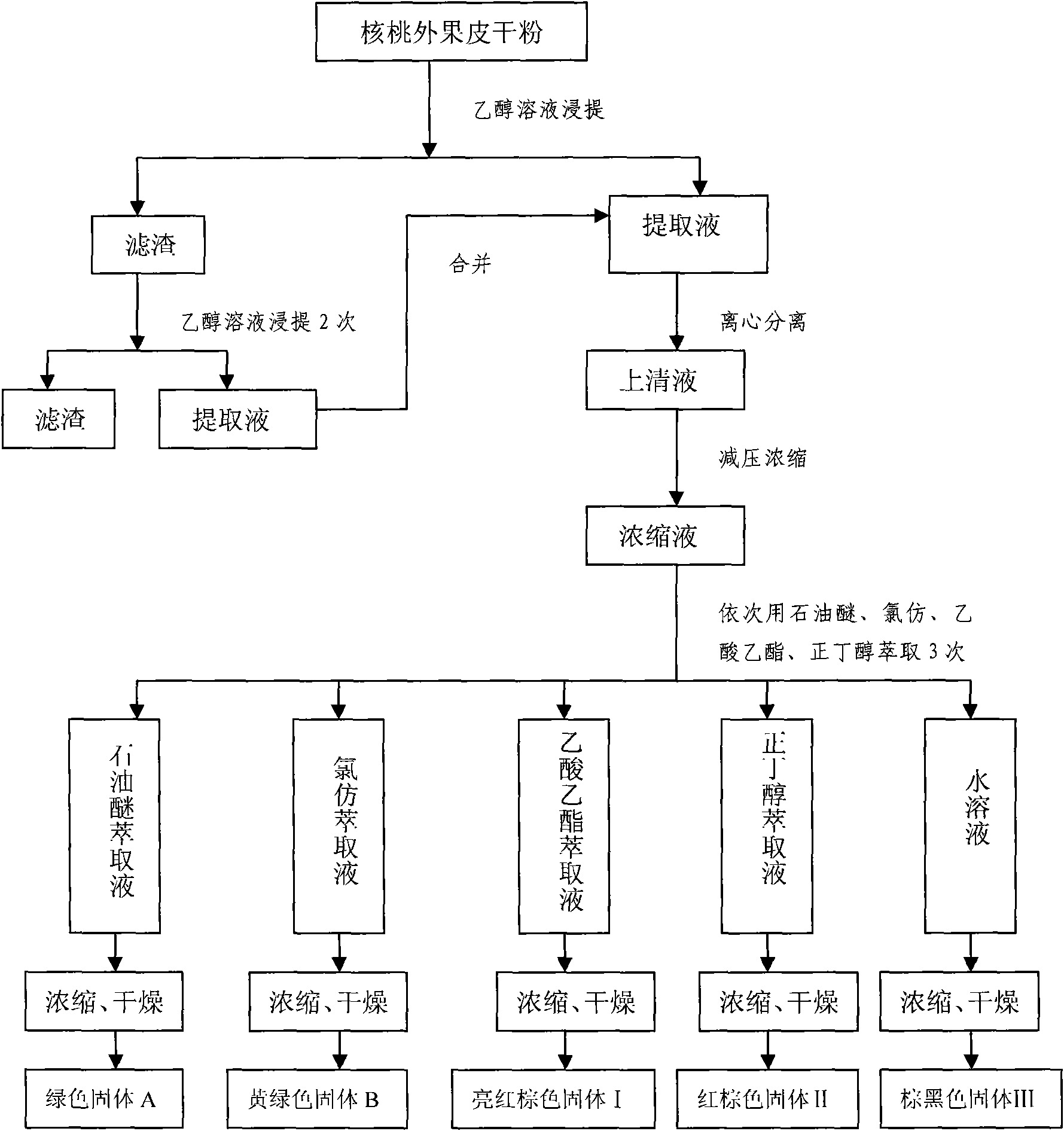

[0023] Embodiment one: the extraction process of walnut exocarp pigment

[0024] Reference attached figure 1 50g of the walnut exocarp powder that crossed a 20 mesh sieve was extracted with 8 times of 80% (v / v) ethanol aqueous solution at 25°C for 3 hours and filtered under reduced pressure, and the filter residue was then washed with 4 times of 80% (v / v) The ethanol was extracted twice, each extraction was 40 minutes, the three filtrates were combined, the insoluble impurities were removed by centrifugation, the temperature was controlled at 60°C in a rotary evaporator, and the volume was concentrated to 300ml.

[0025] Add petroleum ether (30°C to 60°C) to 300ml concentrated solution and extract 3 times, the dosage is 200ml, recover the solvent under reduced pressure at 50°C, spray dry at 50°C to obtain 0.1851g of green pigment A, and extract the residue with chloroform for 3 Each time, the dosage is 200ml, the solvent is recovered under reduced pressure at 50°C, and the ye...

Embodiment 2

[0027] Reference attached figure 1 50g of the walnut exocarp powder that crossed a 60 mesh sieve was extracted with 15 times of 50% (v / v) ethanol aqueous solution at 40°C for 2 hours and filtered under reduced pressure, and the filter residue was extracted twice with 8 times of 50% ethanol. Extract for 40 minutes each time, combine three filtrates, centrifuge to remove insoluble impurities, control the temperature in a rotary evaporator at 60°C, and concentrate to a volume of 300ml. Add petroleum ether (60°C-90°C) to the 300ml concentrated solution and extract 3 times, the dosage is 200ml, recover the solvent under reduced pressure at 60°C, evaporate to dryness at 60°C to obtain 0.064g of green pigment A, and extract the residue with chloroform for 3 Each time, the dosage is 200ml, the solvent is recovered under reduced pressure at 60°C, evaporated to dryness at 60°C to obtain 0.06g of yellow-green pigment B, the residue is extracted with ethyl acetate three times, the dosage ...

Embodiment 3

[0029] Reference attached figure 150g of the walnut exocarp powder that crossed the 80 mesh sieve was extracted with 10 times of 30% (v / v) ethanol aqueous solution at 60°C for 1 hour and then filtered under reduced pressure, and the filter residue was then washed with 5 times of 30% (v / v) The ethanol was extracted twice, each extraction was 40 minutes, the three filtrates were combined, the insoluble impurities were removed by centrifugation, the temperature was controlled at 60°C in a rotary evaporator, and the volume was concentrated to 300ml. Add petroleum ether (60°C to 90°C) to the 300ml concentrated solution and extract 3 times, the dosage is 200ml, recover the solvent under reduced pressure at 70°C, dry in vacuum at 70°C to obtain 0.0055g of green pigment A, and extract the residue with chloroform for 3 Each time, the dosage is 200ml, the solvent is recovered under reduced pressure at 70°C, and the yellow-green pigment B is obtained by vacuum drying at 70°C, which is 0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com