Prestressed plastic corrugated pipe and manufacturing method thereof

A bellows, prestressing technology, applied in the direction of pipes, rigid pipes, pipes/pipe joints/fittings, etc., can solve the problem that the performance of the pipes does not meet the required requirements, the prestressed tendons are easily corroded, and the concrete adhesion is not good. and other problems, to achieve the effect of good insulation, high strength and corrosion prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 50 parts of recycled plastics; 30 parts of pure recycled plastics; 5 parts of preservative BHT; 2 parts of anti-aging agent phosphorothioate; 5 parts of adhesive acrylic resin; 1 part of yellow pigment.

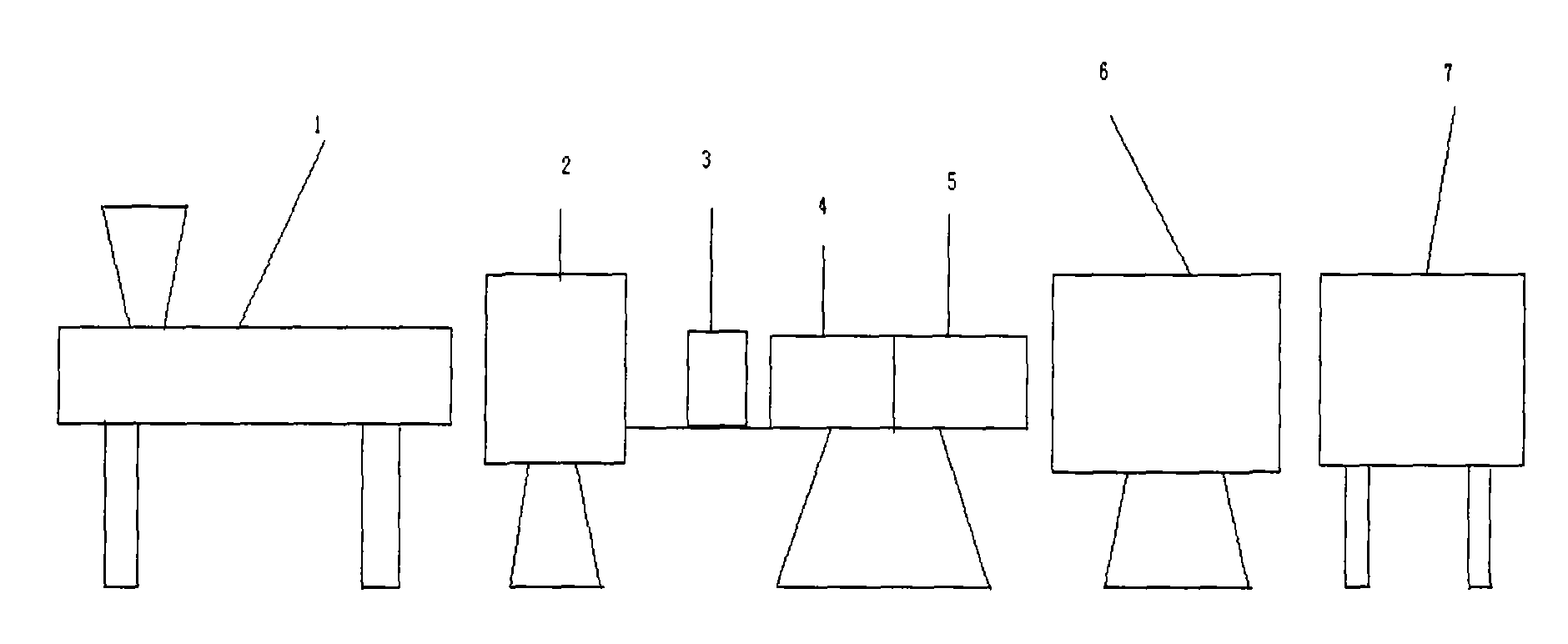

[0034] Production method: first put the above raw materials into the extruder (1) for high-speed melting kneading and mixing for 10 minutes, extrude from the extruder (1) into the extrusion mold (2), and the mold No. 2 can be replaced with different molds ( It is determined according to the diameter of the product), extruded and plasticized at 170°C and processed in the molding machine (3), and reprocessed by heating to 200°C through the heating and reshaping device (4) according to requirements, Then it is cooled to 50° C. by the cooling device (5) for cooling and setting, and the pipe is pulled by (6) at a pulling speed of 3 m / min. Improve its tensile stress, and finally cut the required length by sawing machine (7). 99% of the data of qualified products are determi...

Embodiment 2

[0036] The raw material composition of the prestressed plastic corrugated pipe: 50 parts of recycled plastics; 40 parts of pure recycled plastics; 2 parts of preservative sodium benzoate; 4 parts of anti-aging agent organophosphate (ammonium thiophosphate); 1 part of resin X-158; 2 parts of red pigment.

[0037] Production method: first add the above raw materials into the extruder (1) for high-speed melting kneading and mixing for 30 minutes, and then extrude from the extruder (1) into the extrusion mold (2). Die No. 2 can be replaced with different molds (Determined according to the diameter of the product), extruded and plasticized at 85°C and formed in the molding machine (3), heated at 250°C as required, and the roundness is reprocessed by the reshaping device (4), and then passed The cooling device (5) cools in a water bath at 70°C to shape the pipe, and pulls the pipe through (6), controlling the pulling speed to 3m / min to increase its tensile stress, and finally cuts i...

Embodiment 3

[0039] The raw material composition of prestressed plastic bellows: 40 parts of recycled plastics; 50 parts of pure recycled plastics; 5 parts of preservative calcium propionate; 3 parts of anti-aging phenol; binder bisphenol A polyester resin F-1976 parts; 1 part of blue pigment.

[0040]Production method: first add the above raw materials into the extruder (1) for high-speed melting kneading and mixing for 20 minutes, extrude from the extruder (1) into the extrusion mold (2), and the mold No. 2 can be replaced with different molds ( It is determined according to the diameter of the product), extruded and plasticized at 175°C and formed in the molding machine (3), heated at 220°C as required, and the roundness is reprocessed by the reshaping device (4), and then cooled The device (5) is cooled in a water bath at 50°C to set the shape, and the pipe is pulled by (6), and the pulling speed is controlled to be 2m / min. Improve its tensile stress, and finally cut the required leng...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com