SPS fusion casting preparation method of aerial high-temperature composite material Nb/Nb5Si3

A composite material and high-temperature technology, which is applied in the field of SPS melting and casting preparation of aviation high-temperature composite material Nb/Nb5Si3, can solve the problems of long production cycle, complicated process, high energy consumption, etc., and achieve the effect of rapid response, simple process and uniform structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The raw materials used in the experiment were high-purity Si powder (200 mesh, 99.0%) produced by Shanghai Chemical Reagent Company, and high-purity Nb powder (-325 mesh, 99.9%) produced by Ningxia Dongfang Tantalum Industry Co., Ltd.

[0024] The Nb powder and Si are proportioned according to the molar ratio of Nb-16% Si. The raw materials were then mixed in a blender for 8h. The mixed powder is put into a tower-shaped graphite mold, and placed in a Japanese-made SPS-1050 discharge plasma device for SPS melting and casting synthesis reaction.

[0025] The DC pulse current of the SPS-1050 device used is 5000A, the voltage is 15V, and the pulse cycle is set to 12ms on and 2ms off. The spark plasma sintering temperature parameter is 1800°C, sintering in a vacuum atmosphere, the temperature is raised at a heating rate of 150°C / min, and the reaction temperature and heating rate are controlled by infrared temperature measurement. The applied uniaxial pressure is 0.5KN, and ...

Embodiment 2

[0027] The initial raw materials Nb and Si powder are analytically pure, according to the stoichiometric ratio of Nb-12% Si, the above reagents are accurately weighed with an analytical balance.

[0028] Then the raw materials were mixed in the mixer for 10h. The mixed powder is put into a graphite mold, and placed in a SPS-1050 discharge plasma device for SPS melting and casting synthesis reaction.

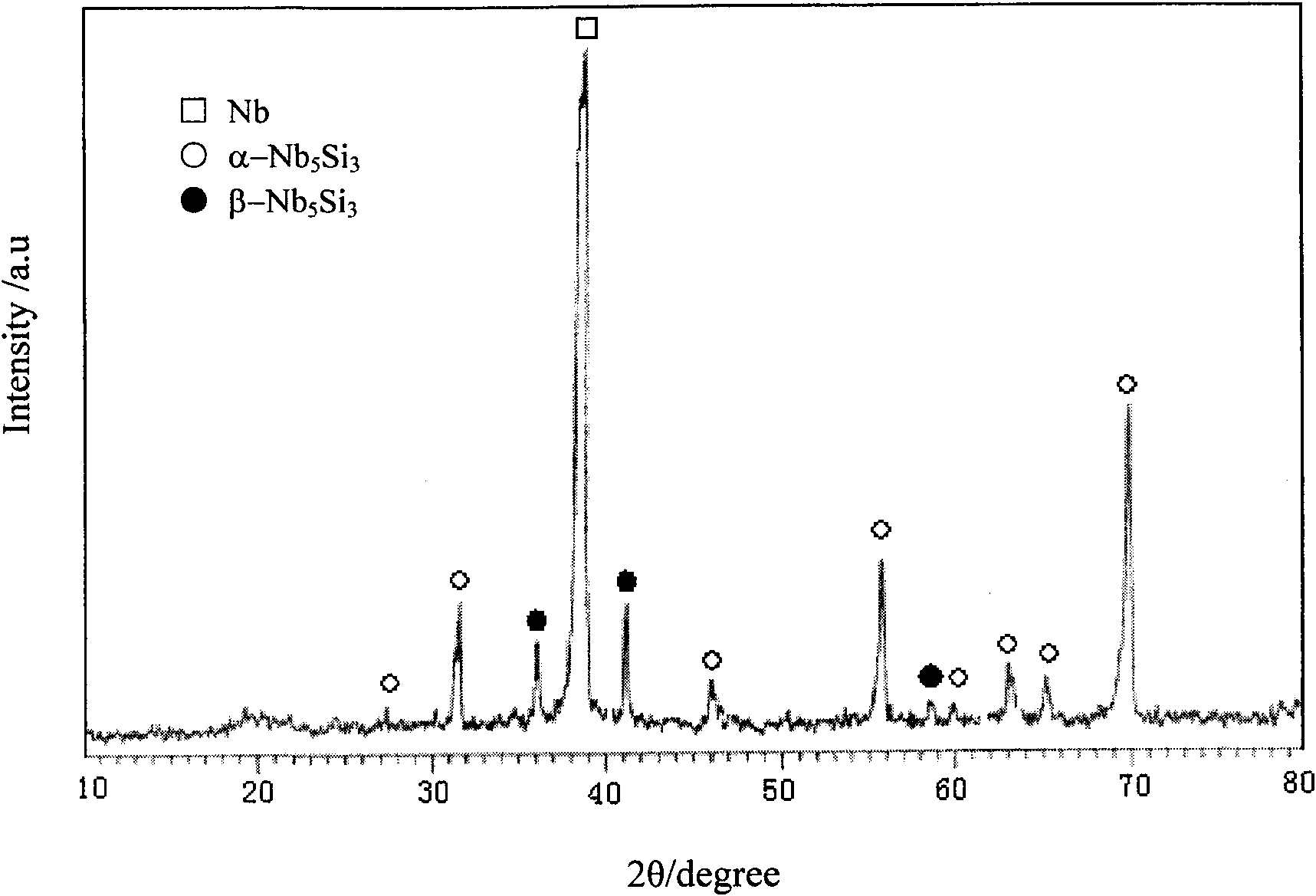

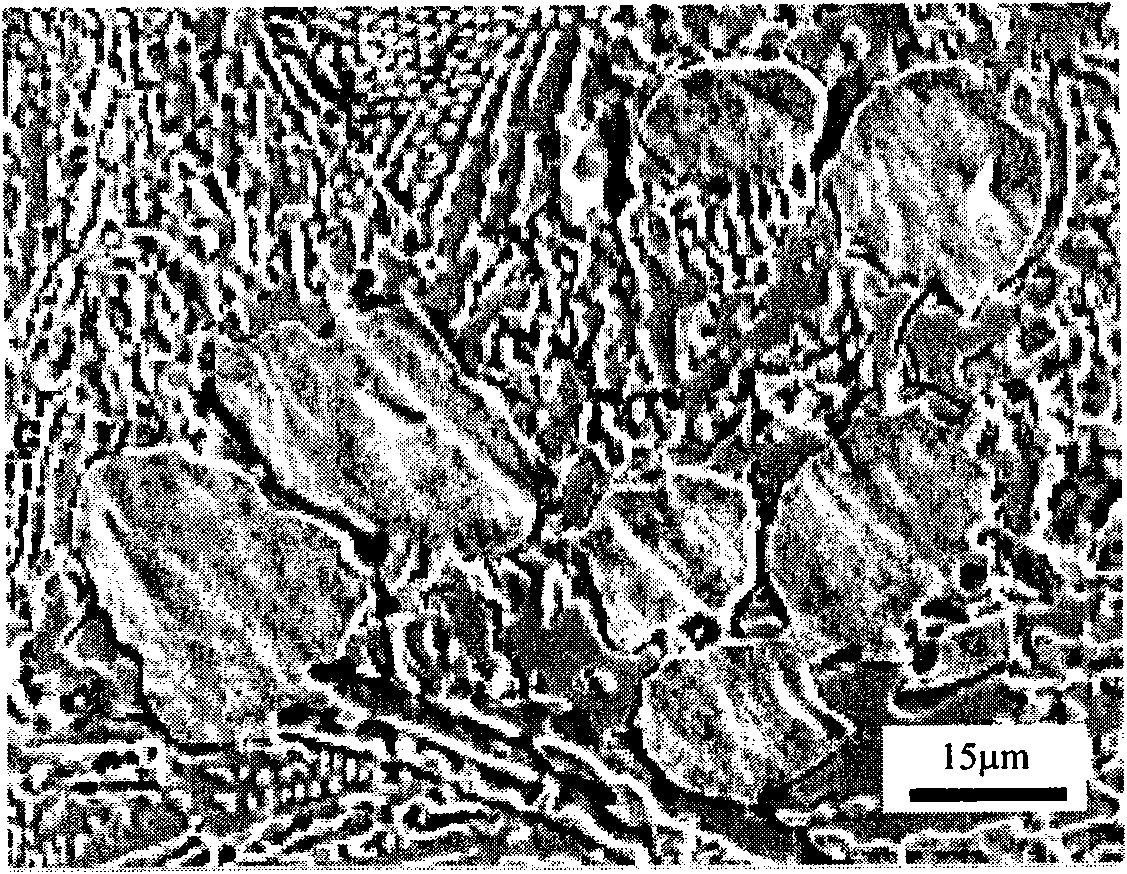

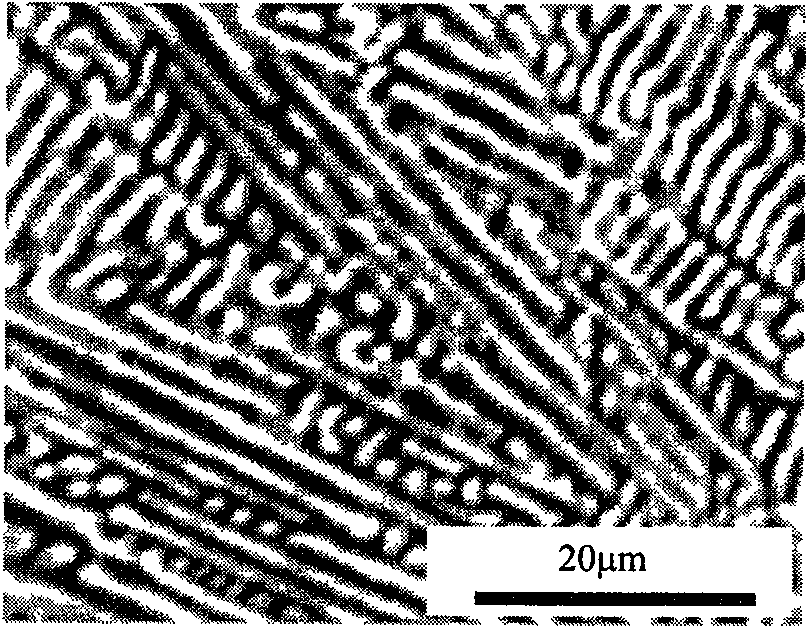

[0029] The DC pulse current of the SPS-1050 device used is 5000A, the voltage is 15V, and the pulse cycle is set to 12ms on and 2ms off. The spark plasma sintering temperature parameter is 1800°C, sintering in a vacuum atmosphere, the temperature is raised at a heating rate of 150°C / min, and the reaction temperature and heating rate are controlled by infrared temperature measurement. The applied uniaxial pressure is 0.5KN, and the reaction synthesis and densification are carried out. integration. The field emission scanning electron image of the longitudinal section of the eute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com