Roof greening system and greening method

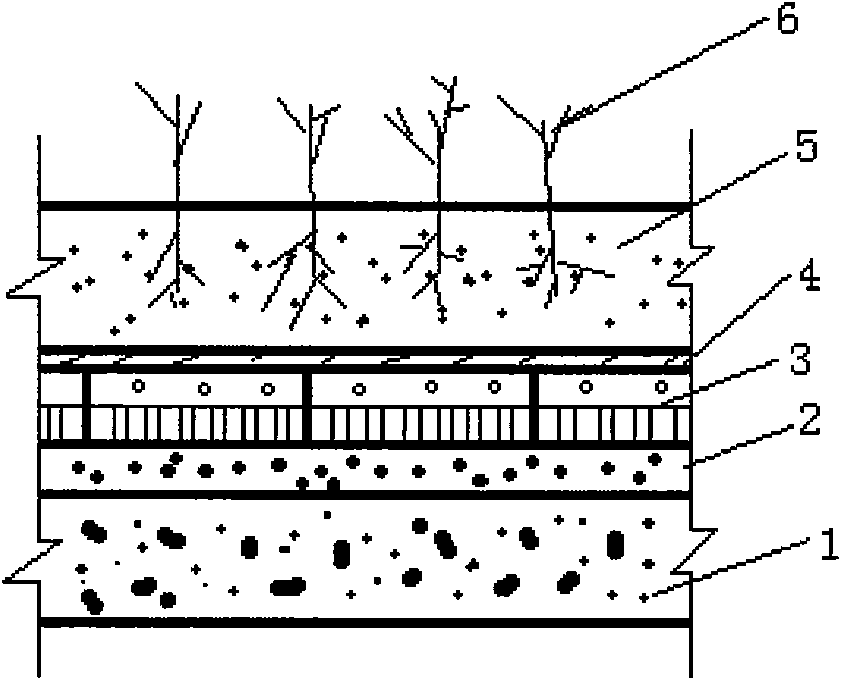

A roof greening and structural layer technology, applied in chemical instruments and methods, roof decoration, building roofs, etc., can solve problems such as non-conformity with environmental protection concepts, environmental pollution, and the inability of clay bricks to be recycled for wall materials, so as to facilitate roof drainage. , good permeability, convenient construction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0096] A flat roof area of 1000m 2 , the construction season is spring, and the local annual rainfall is 1100mm.

[0097] Vegetation layer 6 is selected from S. japonica; the planting layer is designed to have a thickness of 5cm, and a total of 50m of mixed substrate is required 3 .

[0098] Waterproof layer 2 selects the pvc waterproof membrane material of metal carcass for use.

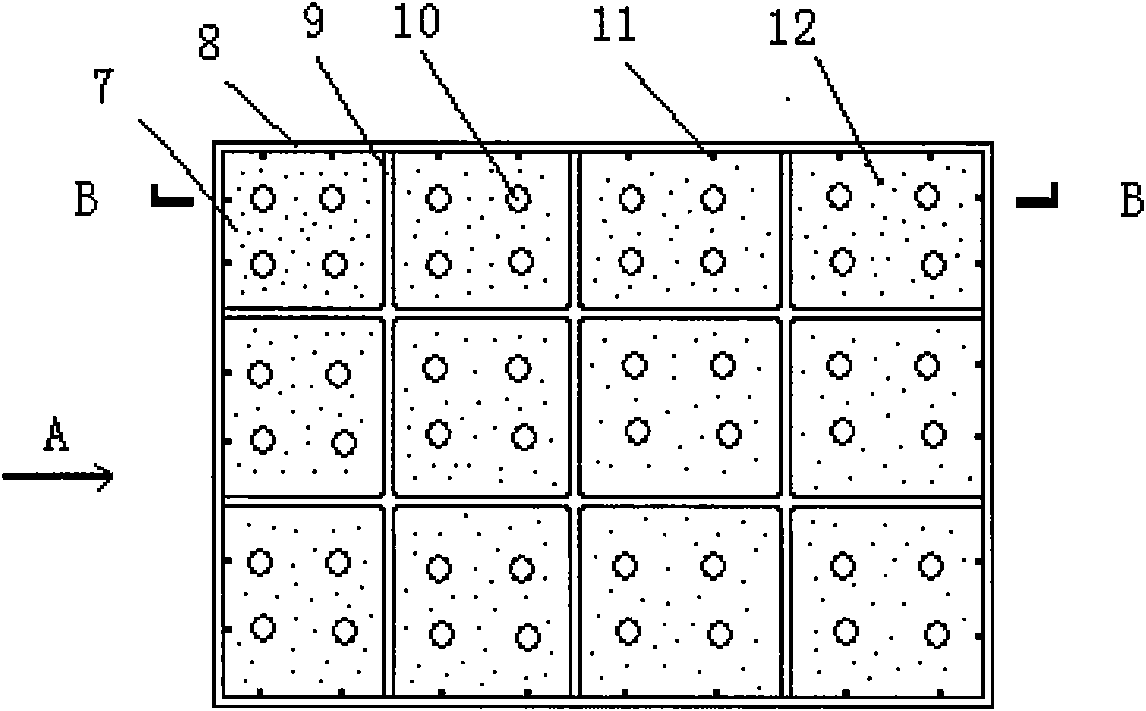

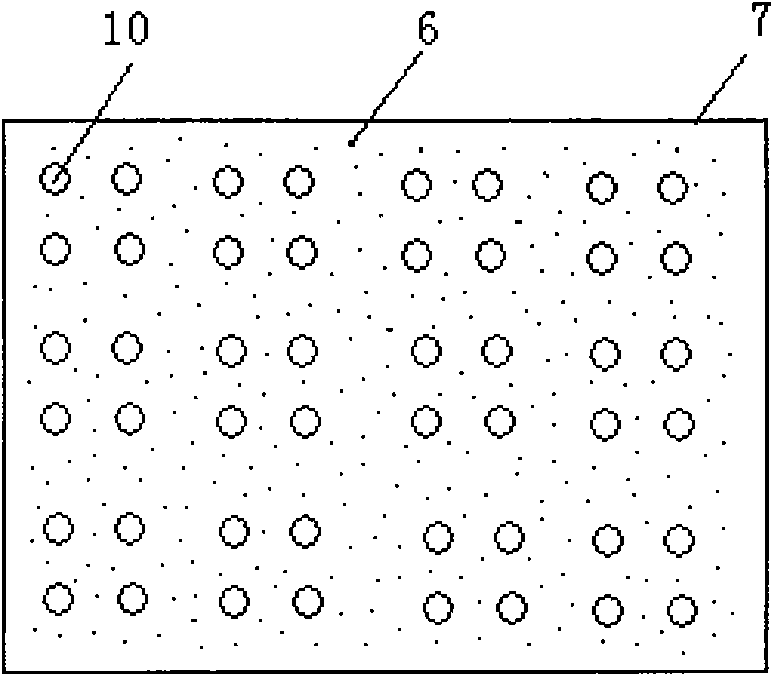

[0099] The drainage layer 3 uses a rectangular plastic water-retaining and draining plate, with an overall size of 0.5m×1m; the thickness of the plate 7, the edge reinforcing rib 8, the middle reinforcing rib 9, the reinforcing column 11 and the sinker wall 14 are all 3mm; cylindrical The hollow sinker 10 has an inner diameter of 15mm and a spacing of 20mm.

[0100] The diameter of the plate through hole 12 is 4mm, and the diameter of the rib plate through hole 13 is 8mm;

[0101] The height of the middle reinforcement rib 9 and the reinforcement column 11 is 20mm, and the height of the edge r...

Embodiment 2

[0133] A flat roof area of 2000m 2 In summer, the construction season, the local annual rainfall is 900mm.

[0134] Vegetation layer 6 is made of 50% S. japonica and 50% Rhodiola rosea, planted in rows at intervals; the design thickness of the planting layer is 6cm, and a total of 120m of mixed substrates are required 3 .

[0135] Waterproof layer 2 is made of EPDM waterproof membrane with metal carcass;

[0136] The drainage layer 3 uses a rectangular plastic water-retaining and draining plate, with an overall size of 0.5m×1m; the thickness of the plate 7, the edge reinforcing rib 8, the middle reinforcing rib 9, the reinforcing column 11 and the sinker wall 14 are all 3mm; cylindrical The hollow sinker 10 has an inner diameter of 15mm and a spacing of 20mm.

[0137] The diameter of the plate through hole 12 is 3 mm, and the diameter of the rib plate through hole 13 is 7 mm;

[0138] The height of the middle reinforcement rib 9 and the reinforcement column 11 is 20mm, a...

Embodiment 3

[0171] A flat roof area of 5000m 2 , In winter during the construction season, the local annual rainfall is 1500mm.

[0172] The vegetation layer is selected from S. japonica; the planting layer is designed to have a thickness of 4cm, and a total of 200m of mixed substrates are required 3 .

[0173] The waterproof layer is made of ternary butyl rubber waterproof membrane with metal carcass;

[0174] Rectangular plastic water-retaining and draining boards are used for the drainage layer, with a size of 0.5m×1m; the thickness of the flat plate 7, the edge reinforcing rib 8, the middle reinforcing rib 9, the reinforcing column 11 and the sinker wall 14 are all 3mm; the cylindrical hollow sinker The groove 10 has an inner diameter of 15 mm and a pitch of 20 mm.

[0175] The diameter of the plate through hole 12 is 4mm, and the diameter of the rib plate through hole 13 is 8mm;

[0176] The height of the middle reinforcement rib 9 and the reinforcement column 11 is 20mm, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com