Method for preparing carbon supported transition metal phosphide material

A transition metal and phosphide technology, applied in the field of carbon-supported phosphide preparation, can solve problems such as no occurrence, and achieve the effect of simplifying the preparation steps and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

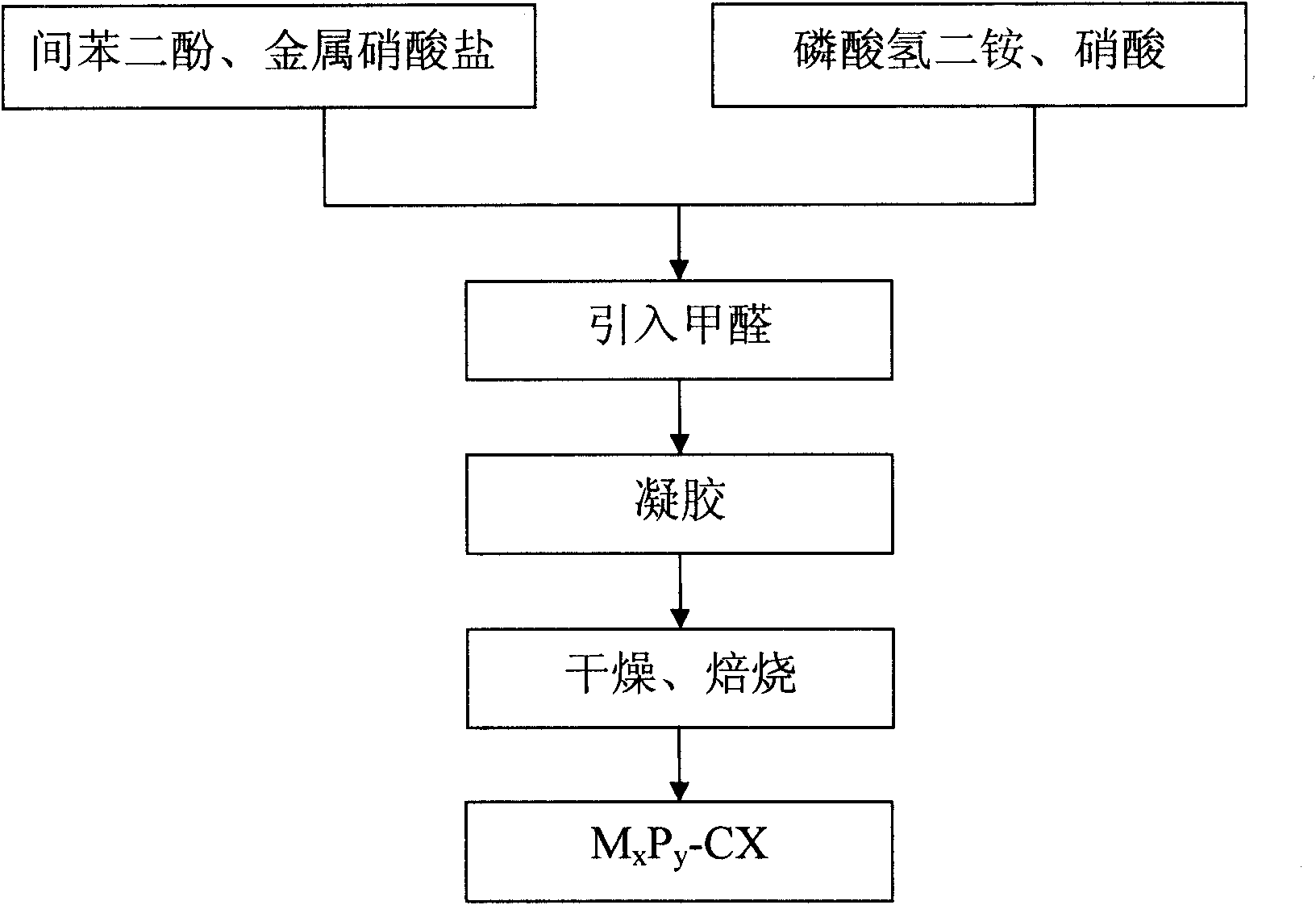

Method used

Image

Examples

Embodiment 1

[0030] Add 3.17g resorcinol (R) into 4.0g deionized water (W) and stir to dissolve, then add 0.35g Ni(NO 3 ) 2 ·6H 2 O, add 0.08g (NH 4 ) 2 HPO 4 , at this time, phosphate precipitates are formed, and concentrated HNO is added dropwise 3 Dissolve the precipitate, adjust the pH to 2-3 at the same time, and add 4.67g of 37wt% formaldehyde (F) solution dropwise under stirring condition. After the formaldehyde is added, the mixed solution will quickly gel into a solid polymer. The resulting polymer was transferred to a vacuum drying oven, and dried at 85° C. for 5 to 7 days to obtain a xerogel. Under the protection of nitrogen (75ml / min), the xerogel was raised to 800°C at a heating rate of 2°C / min, and calcined at this temperature for 3 hours to prepare metal nickel phosphide-modified gel carbon. Using the same method, we also prepared cobalt phosphide and iron phosphide modified gel carbon, and different metals were used in the same molar amount in the preparation process....

Embodiment 2

[0032] Preparation of transition metal phosphide-supported gel carbon materials by a step-by-step method. The method is as follows: first, according to the method in Example 1, under the situation of not introducing phosphide and metal ion salt, in N 2 Under roasting, the gelled carbon is prepared. Get 1.0g of this gelled carbon in a beaker, put 0.148g Ni(NO 3 ) 2 ·6H 2 O or Co(NO 3 ) 2 ·6H 2 O or 0.216g Fe(NO 3 ) 2 9H 2 O was dissolved in 1.5 ml of water, and 0.1 g of concentrated HNO was added dropwise to the water 3 , and then add 0.034g (NH 4 ) 2 HPO 4 After stirring and dissolving, the solution was added dropwise to the gel carbon, dried at 120°C, and dried at 800°C N 2 Under protection, calcined for 3 hours to obtain gel carbon supported by transition phosphide.

Embodiment 3

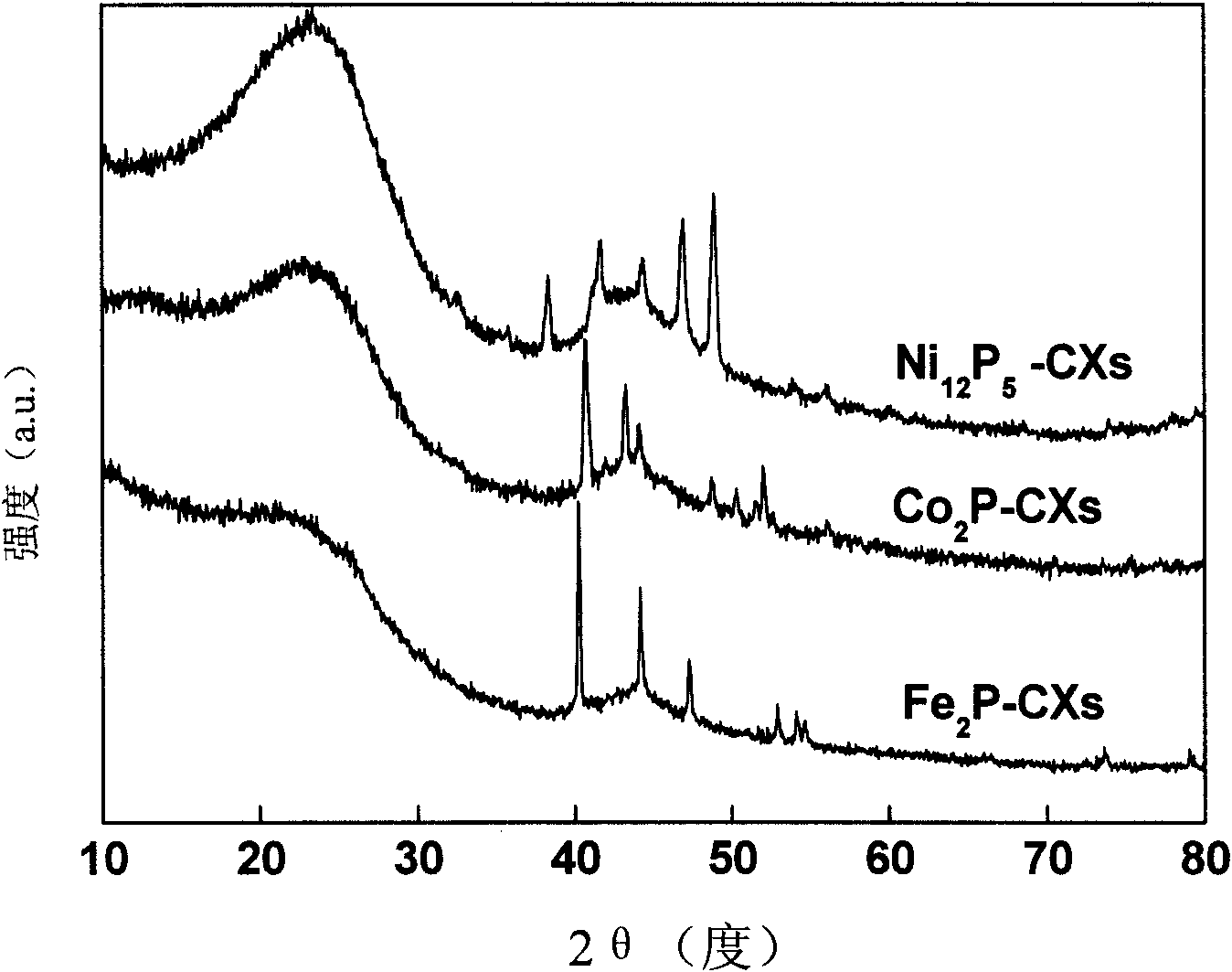

[0034] XRD diffraction test showed that in N 2 The crystal forms of the transition metal phosphides modified by roasting in the atmosphere are Fe 2 P, Co. 2 P, Ni 12 P 5 . See figure 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com