Inclined tube floating device for waste water treatment

A wastewater treatment and inclined tube technology, applied in water/sewage multi-stage treatment, flotation water/sewage treatment, water/sludge/sewage treatment, etc. Easy to block and other problems, to achieve the effect of saving floor space and material consumption, strengthening the sludge concentration effect, and reducing the moisture content of the scum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

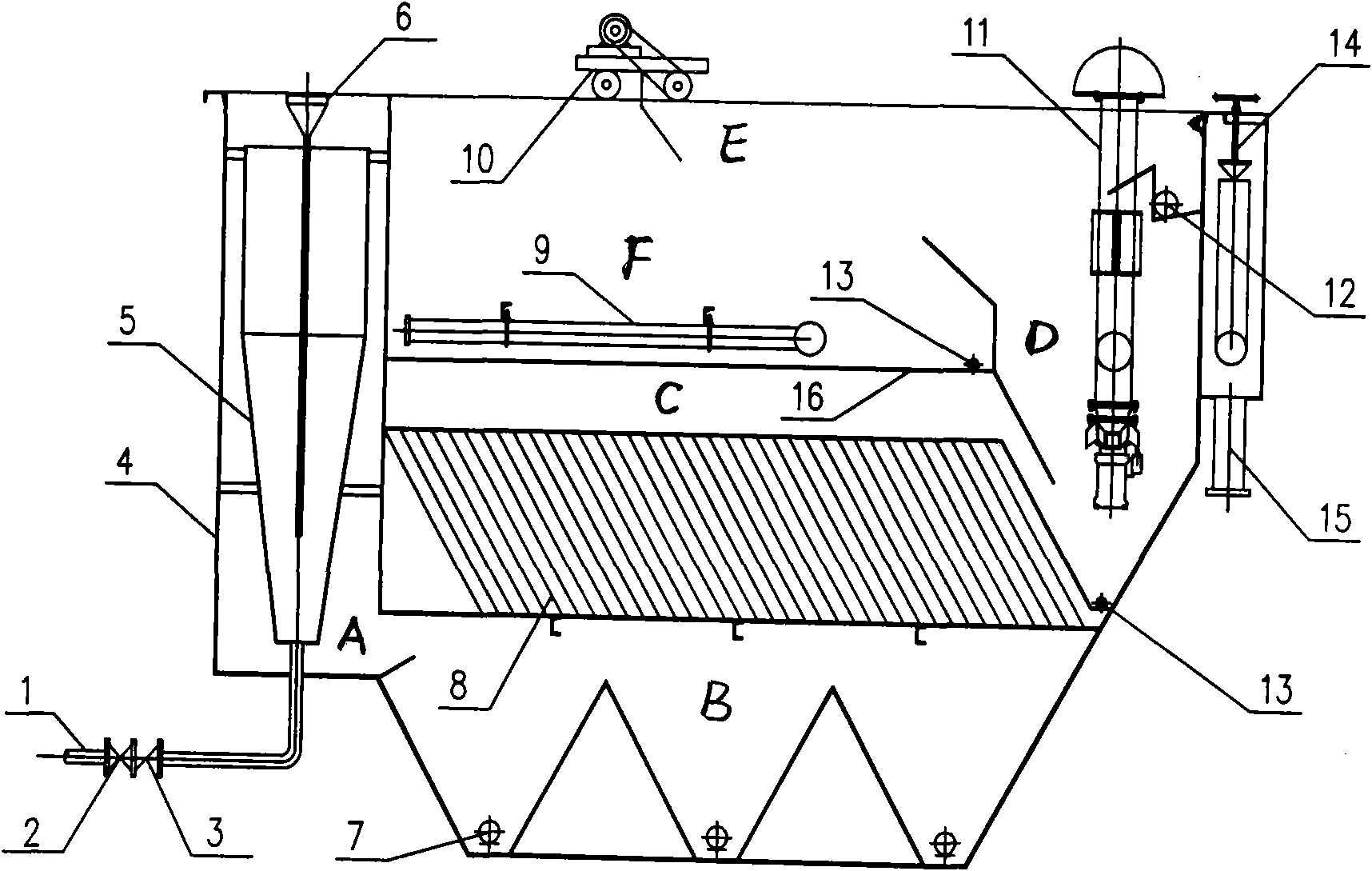

[0007] The present invention will be further described below in conjunction with the drawings:

[0008] As shown in the figure, 1 is the water inlet pipe, 2 is the manual or electric butterfly valve, 3 is the check valve, 4 is the outer wall of the water tank, 5 is the cyclone mixer, 6 is the dosing device, 7 is the bottom mud pipe, 8 is the oblique Plate packing, 9 is the water collecting pipe, 10 is the slagging crane, 11 is the polyoxygen activation aerator, 12 is the scum discharge pipe, 13 is the middle mud pipe, 14 is the water level regulator, 15 is the drain pipe, 16 is the Deflector. A is the diversion zone, B is the settlement zone, C is the buffer zone, D is the dissolved gas zone, E is the reaction zone, and F is the catchment zone.

[0009] The water inlet pipe 1 is in communication with the cyclone mixer 5 at the front end of the equipment. The cyclone mixer 5 is placed in the diversion area A, and the sewage enters the main part of the equipment through the diversio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com