Device for preparing semi-solid alloy rheological slurry or blank

A semi-solid metal and slurry technology, which is applied in the field of devices for preparing large-scale semi-solid alloy rheological slurry or blanks, and in the field of devices for preparing semi-solid alloy rheological slurry or blanks, which can solve the problem of inability to produce large-scale semi-solid alloys Problems such as alloy slurry or billet, uneven distribution of temperature field and structure, difficulty in producing semi-solid slurry or billet, etc., achieve great practical significance and practical value, good shape, and balanced temperature field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

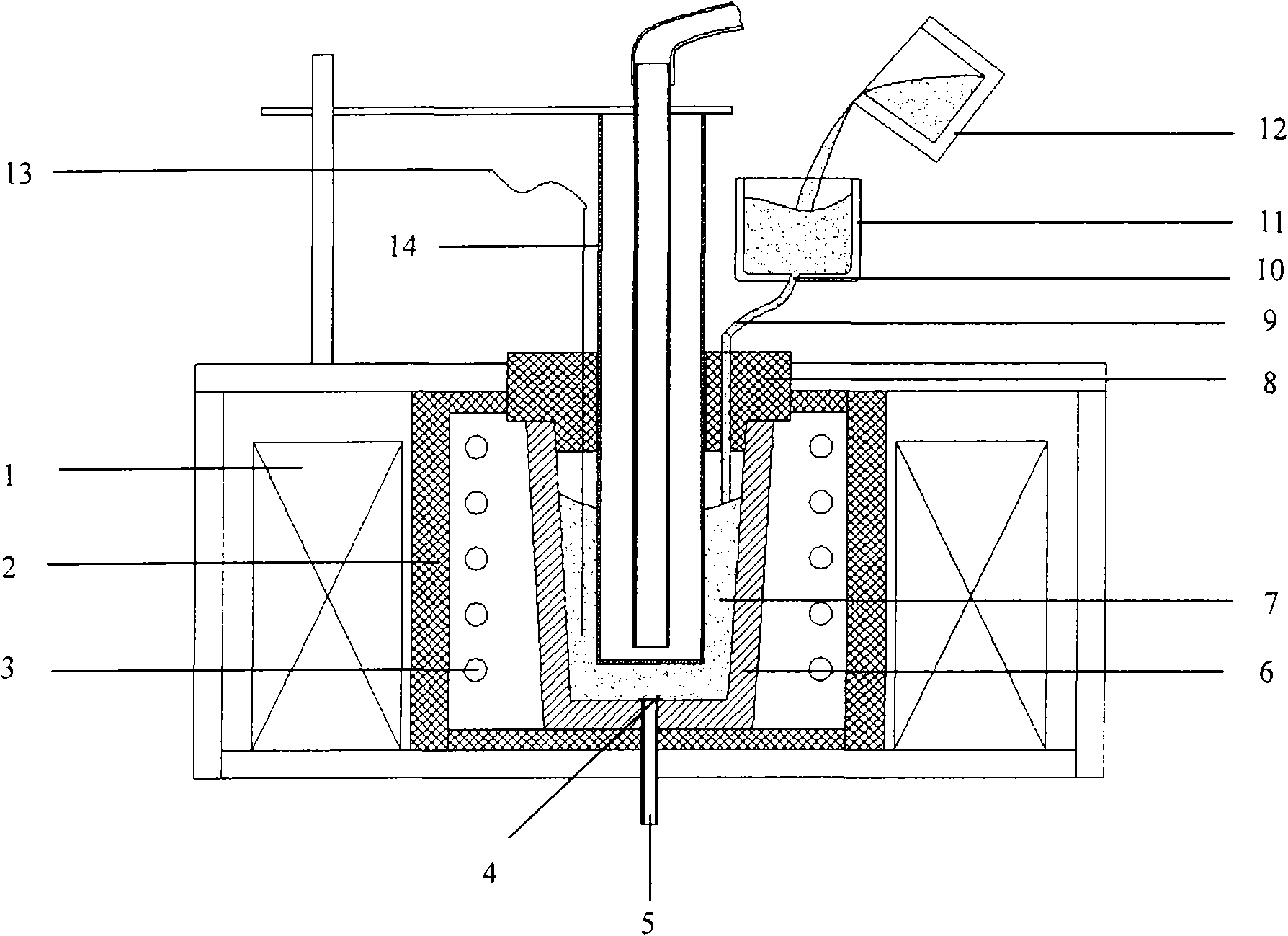

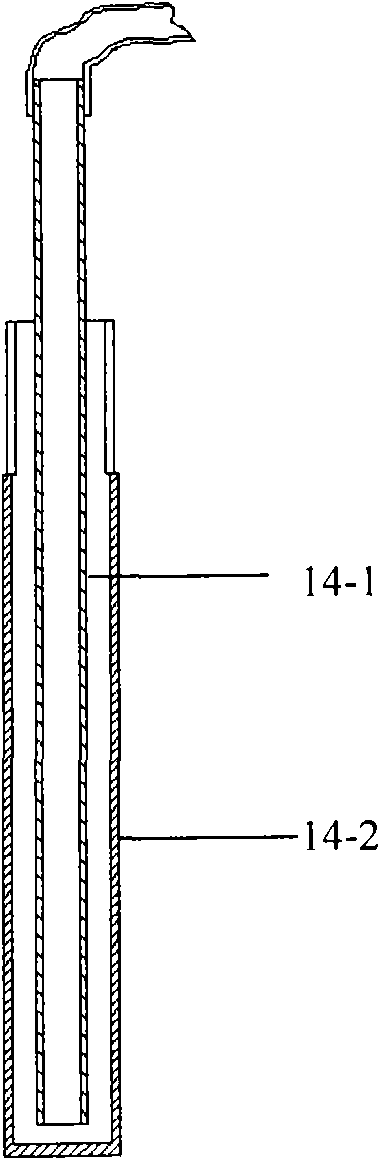

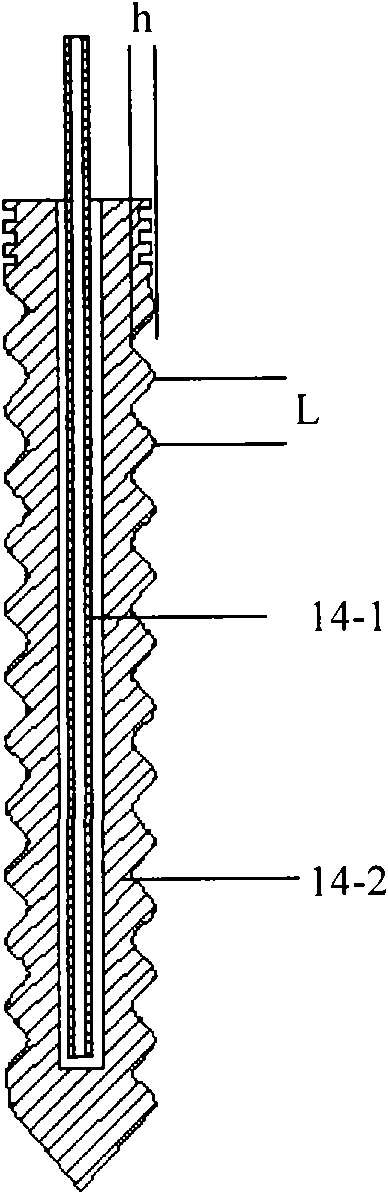

[0042] figure 1 It is a schematic diagram of the device for preparing semi-solid metal rheological slurry or billet, such as figure 1 As shown, the device includes a preparation crucible 6, and an external cooling controller 3, a heat preservation system 2, and an electromagnetic stirrer 1 are sequentially arranged on the periphery of the preparation crucible 6 from the inside to the outside; 11, the static crucible 11 is communicated with the preparation crucible 6 through the heat preservation cover 8 on the preparation crucible 6 through the guide tube 9 at the bottom, and a melting crucible 12 is arranged on the top of the static crucible 11; and in the preparation crucible 6 The bottom is provided with a draft tube 5, and the draft tube 5 at the bottom of the described preparation crucible 6 and the bottom draft tube 9 of the described melting crucible 12 all have valves 4, 10; the middle part of the described preparation crucible is provided with There is an internal co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com