High energy ultrasound extraction

A technology of extracting liquid and ultrasonic wave, applied in the field of liquid phase extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

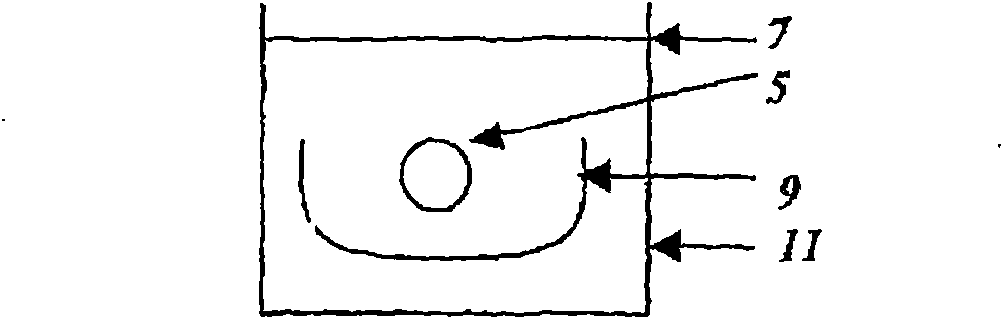

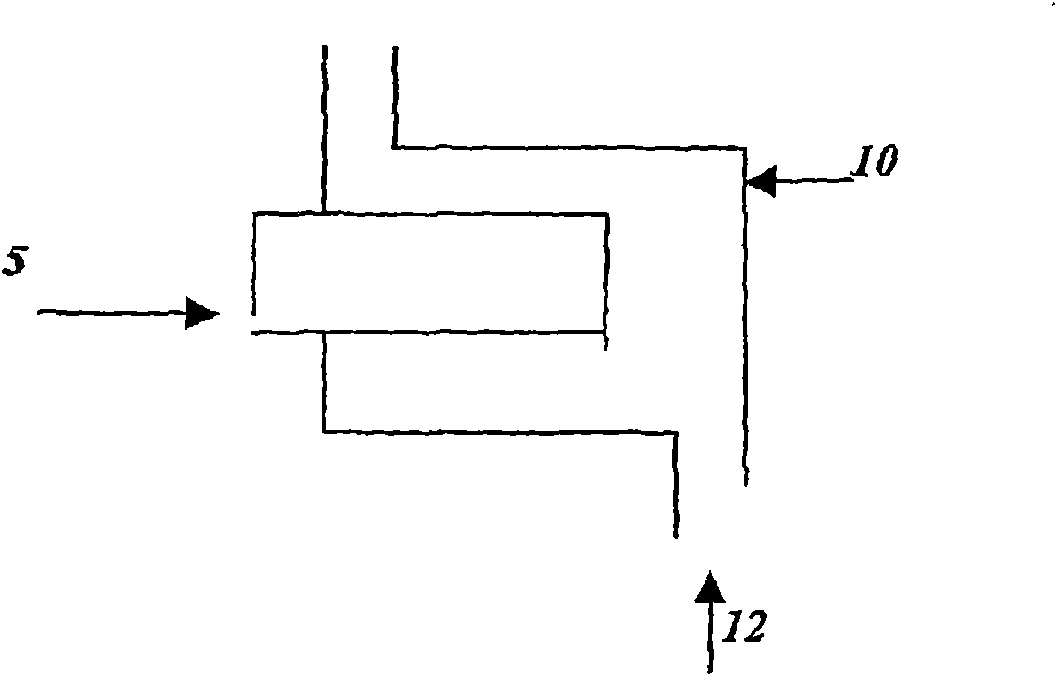

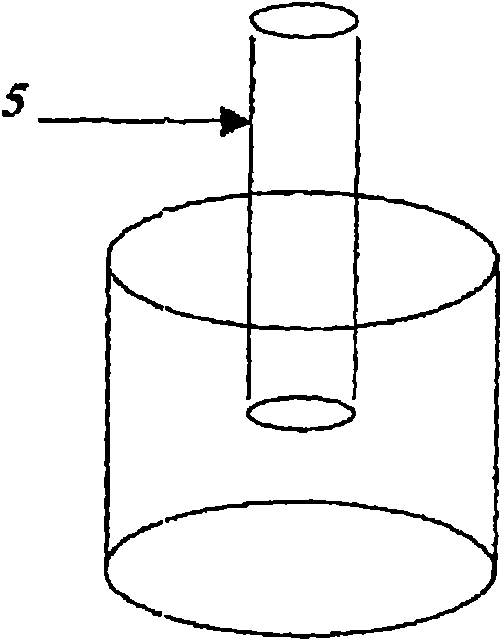

Method used

Image

Examples

Embodiment

[0078] Oak Flavor Extraction

[0079] Use 150ml tap water or 12% ethanol / water or 100% ethanol to extract 40g oak. The sample was stirred (control sample) or sonicated for 10 seconds and 30 seconds, and then the liquid sample was sieved (about 0.8mm mesh), and then filtered with No. 1 Whitman filter paper. The filtrate sub-sample was diluted 3.5 times with water and sent to the Australian Wine Research Institute for oak flavor analysis by GC-MS.

[0080] Result

[0081] The quantitative limit of chemical substances identified by GC-MS (the amount expressed in μg / L in the diluted extract) is guaiacol 3.5, eugenol 35, oak lactone 35, vanillin 35 and furfural 35. Other chemical substances analyzed but below the quantitative limit are: 4-methylguaiacol, 4-ethylphenol, 4-ethylguaiacol and 5-methylguaiacol.

[0082] The extraction data shows that in the same extraction time, compared with the control sample, the use of the above method for ultrasonic treatment can promote the extraction o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com