Preparation method of compound nanotube photocatalytic film of titanium dioxide and silicon dioxide

A technology of photocatalytic thin film and silicon dioxide, which is applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as difficult to solve load problems, loss of catalytic effect, complex process, etc., and achieve excellent Effects of photocatalytic performance, strong process repeatability, and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

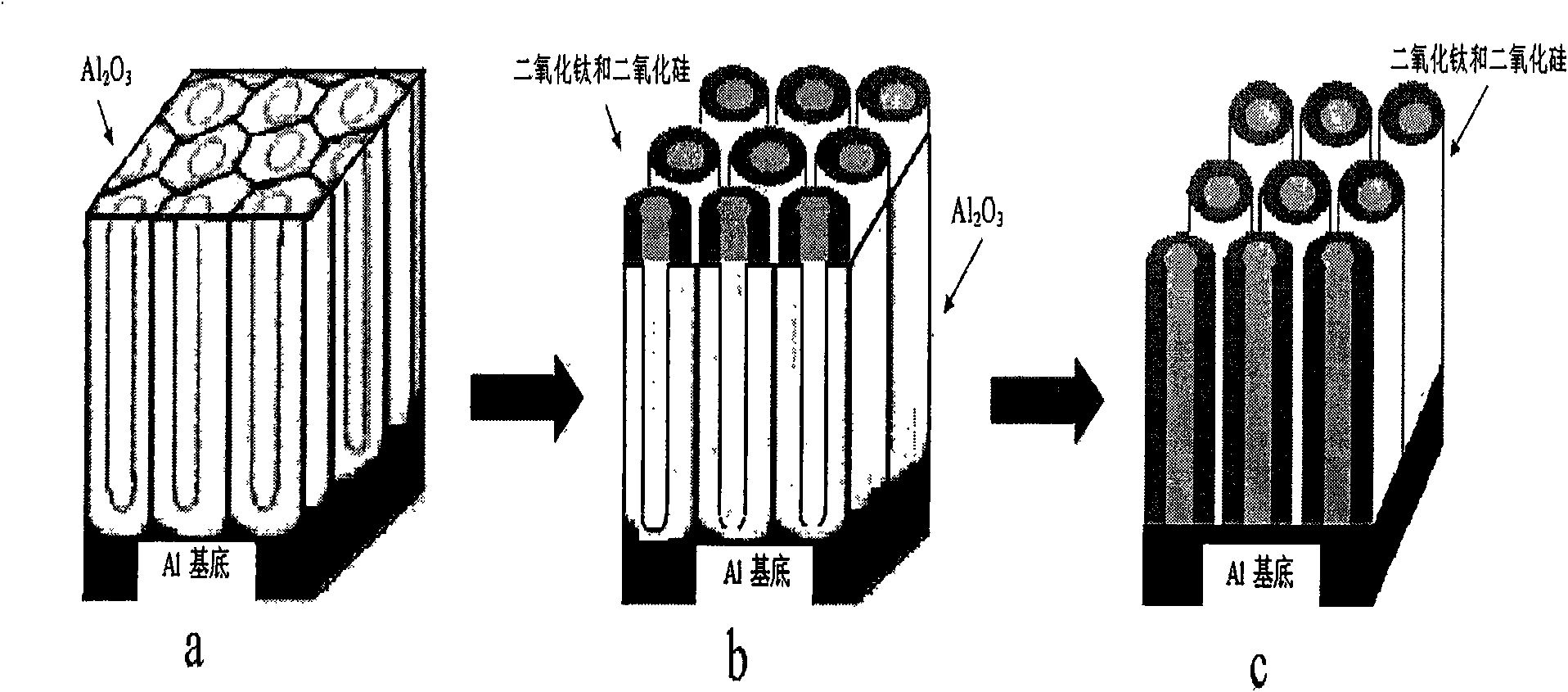

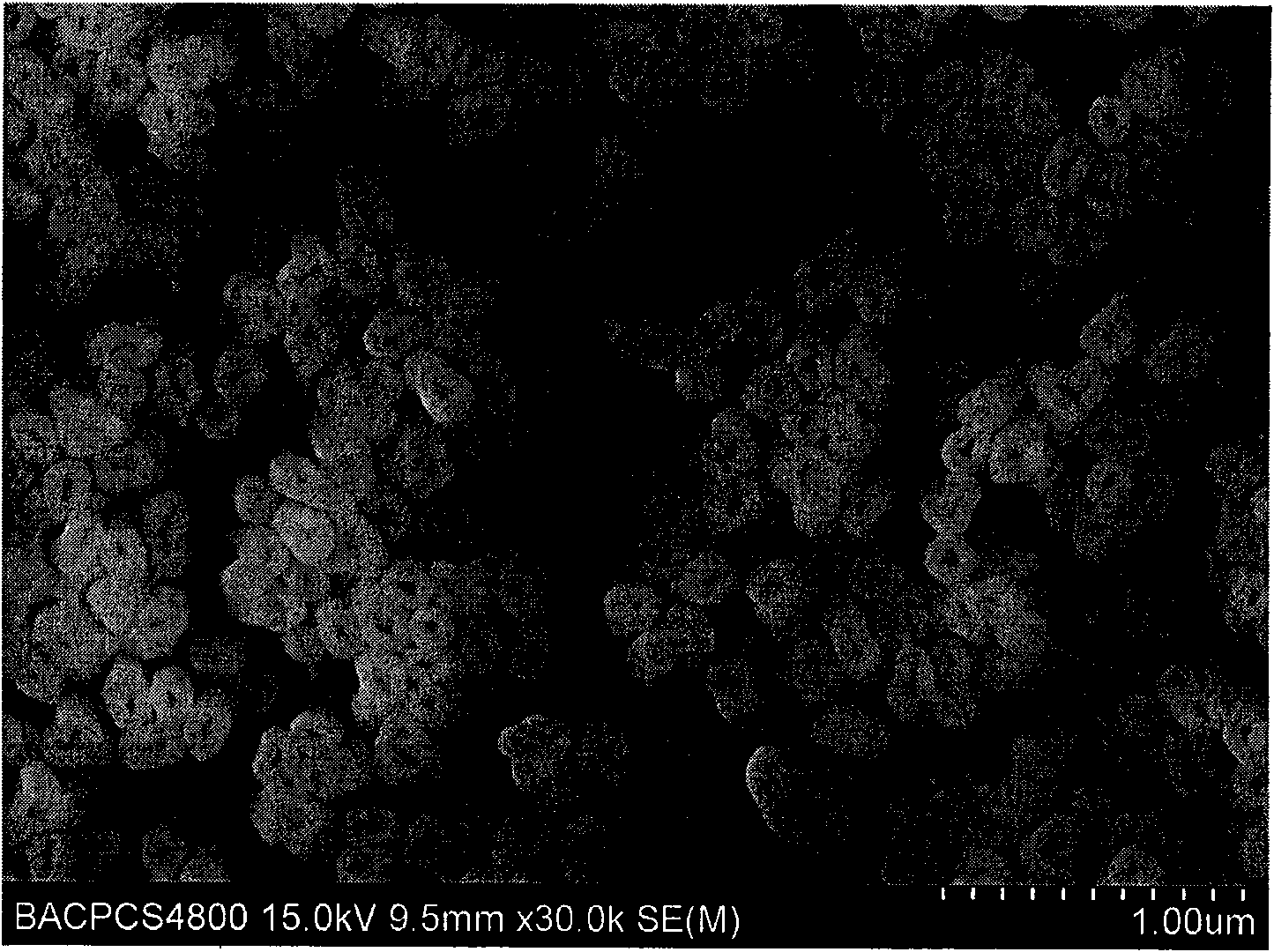

Method used

Image

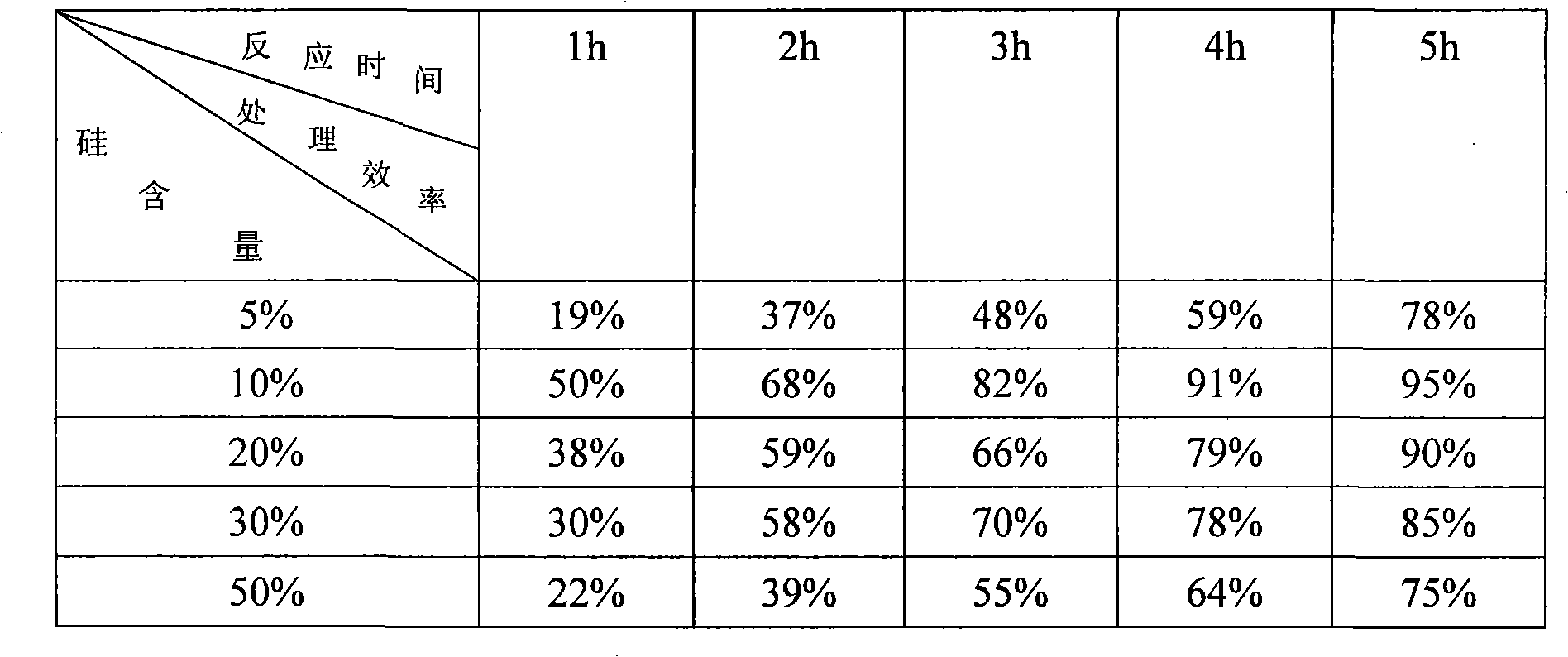

Examples

Embodiment 1

[0018] Anodize the metal aluminum sheet with H at a concentration of 0.5M 3 PO 4 It is an electrolytic solution, the oxidation voltage is 100V, and the oxidation time is 10h. The aluminum substrate on which the anodized aluminum oxide template (AAO) has been grown after anodic oxidation is taken out and cleaned with deionized water before use. 0.5mol / L (NH 4 ) 2 TiF 6 and 0.5mol / L (NH 4 ) 2 SiF 6 The mixed solution was mixed according to the ratio of atomic content Si:Ti=5% to form a liquid phase deposition solution, which was fully stirred and placed in a water bath at 30°C for later use. Dip the AAO template into (NH 4 ) 2 TiF 6 and (NH 4 ) 2 SiF 6 After 15 minutes of deposition in the mixed solution, take it out, wash it with deionized water and dry it. Then heat up at 400°C for 3 hours and cool to room temperature with the furnace.

Embodiment 2

[0020] Anodize the metal aluminum sheet with H at a concentration of 0.5M 3 PO 4 It is an electrolytic solution, the oxidation voltage is 80V, and the oxidation time is 12h. The aluminum substrate on which the anodized aluminum oxide template (AAO) has been grown after anodic oxidation is taken out and cleaned with deionized water before use. 0.1mol / L (NH 4 ) 2 TiF 6 and 0.1mol / L (NH 4 ) 2 SiF 6 The mixed solution is mixed according to the ratio of atomic content Si:Ti=10% to form a liquid phase deposition solution, which is fully stirred and placed in a 35°C water bath for later use. Dip the AAO template into (NH 4 ) 2 TiF 6 and (NH 4 ) 2 SiF 6 After stirring and depositing in the mixed solution for 20 minutes, take it out, wash it with deionized water and dry it. Then heat up at 500°C for 2 hours and cool to room temperature with the furnace.

Embodiment 3

[0022] Anodize the metal aluminum sheet with H at a concentration of 1M 3 PO 4 It is an electrolytic solution, the oxidation voltage is 100V, and the oxidation time is 10h. The aluminum substrate on which the anodized aluminum oxide template (AAO) has been grown after anodic oxidation is taken out and cleaned with deionized water before use. 0.05mol / L (NH 4 ) 2 TiF 6 and 0.05mol / L (NH 4 ) 2 SiF 6 The mixed solution is mixed according to the ratio of atomic content Si:Ti=20% to form a liquid phase deposition solution, which is fully stirred and placed in a water bath at 40°C for later use. Dip the AAO template into (NH 4 ) 2 TiF 6 and (NH 4 ) 2 SiF 6 After stirring and depositing in the mixed solution for 30 minutes, take it out, wash it with deionized water and dry it. Then heat up at 500°C for 3 hours and cool to room temperature with the furnace.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com