Zirconia titanium dioxide composite nano tube photocatalysis film material and preparation method thereof

A photocatalytic film, titanium dioxide technology, applied in chemical instruments and methods, physical/chemical process catalysts, nanotechnology and other directions, can solve the complex process of titanium dioxide composites, difficult to solve the problem of loading, difficult to recycle and other problems, to achieve easy operation, Good nanotube morphology and easy recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

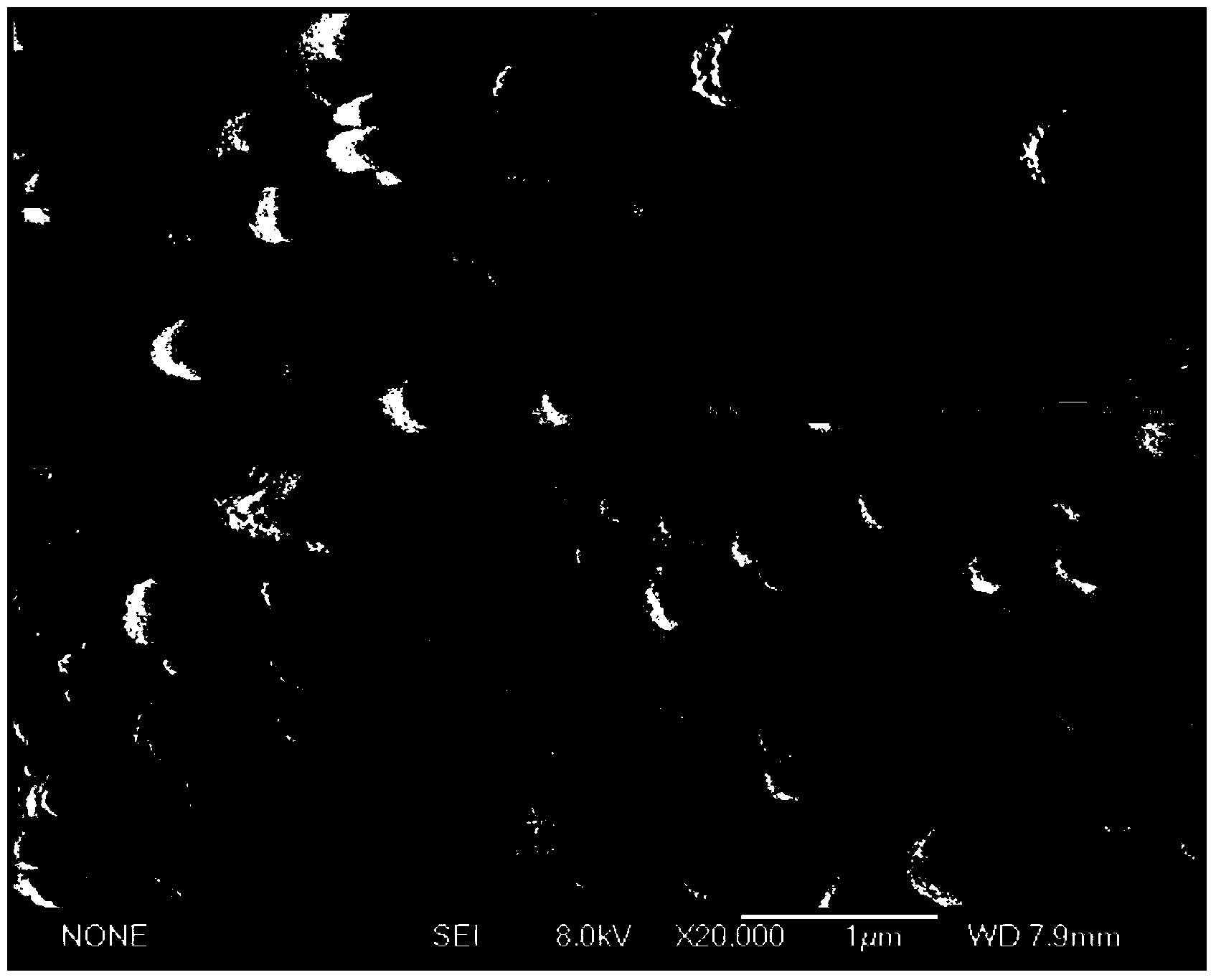

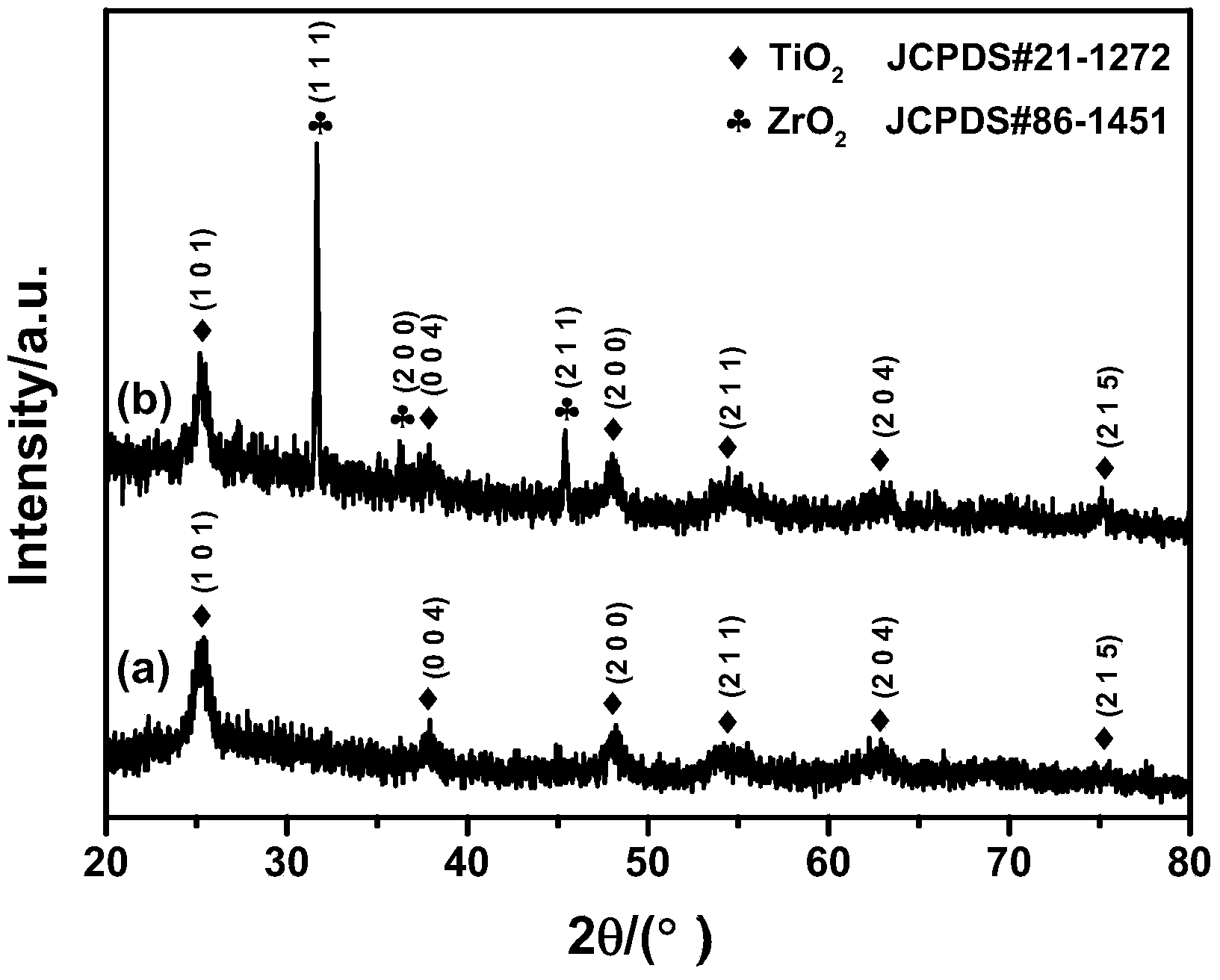

[0021] (1) A porous anodized aluminum oxide film with a pore size of about 200 nm and a thickness of 50 μm is used as a template;

[0022] (2) Configure zirconium nitrate solution and titanium tetrafluoride solution: take 0.429g zirconium nitrate and 1.201g urea and dissolve them in 100ml deionized water, stir evenly at room temperature to obtain 0.01M zirconium nitrate solution;

[0023] Dissolve 0.74g of titanium tetrafluoride in 150ml of deionized water, and stir at room temperature to obtain a 0.04M aqueous solution of titanium tetrafluoride;

[0024] (3) Put a porous anodized alumina template with a pore size of about 200nm and a thickness of 50μm in a 0.01M zirconium nitrate solution, let it stand for 14 hours, and keep the solution temperature at 60°C;

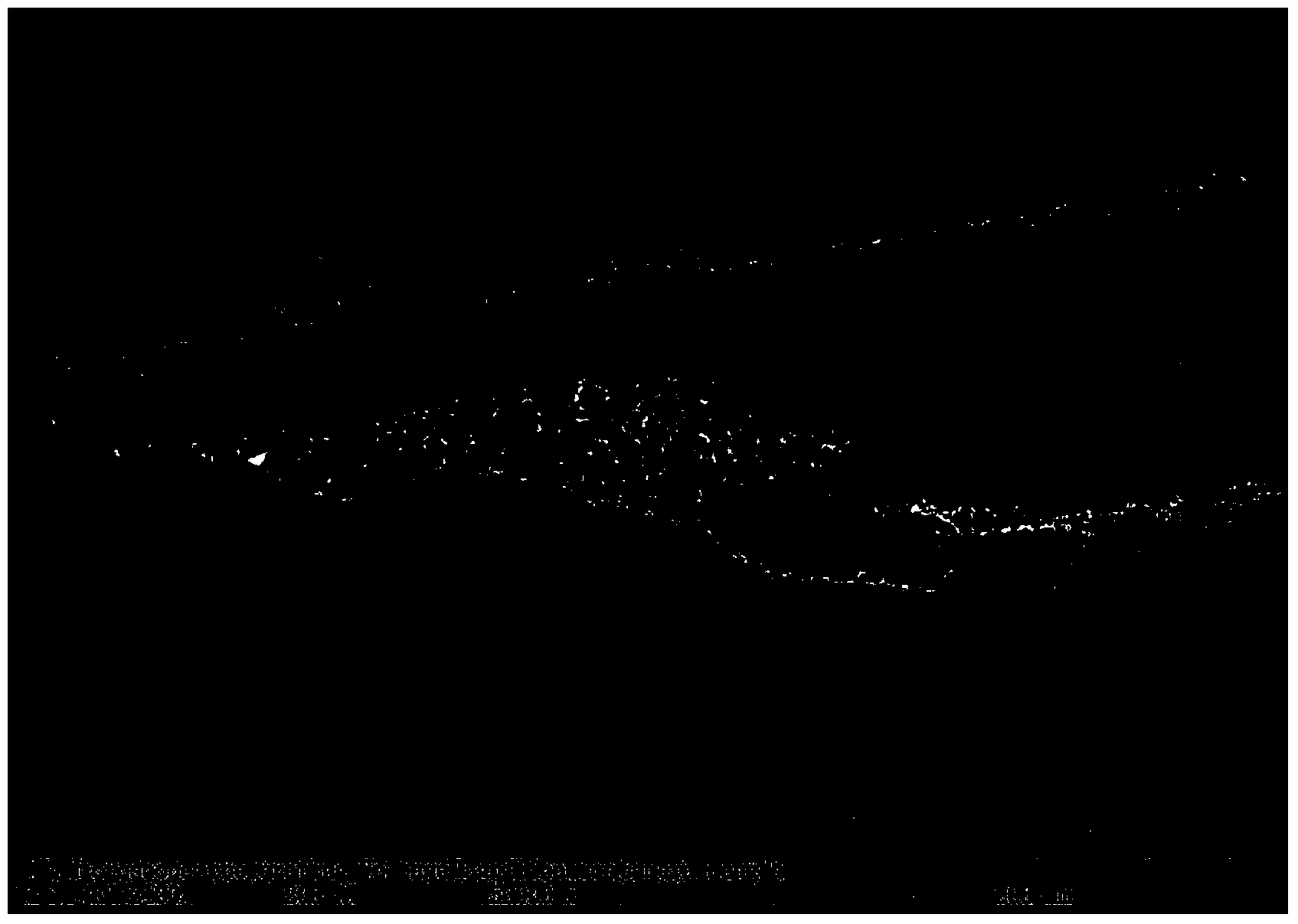

[0025] (4) The above-mentioned anodized alumina template deposited with zirconium nitrate solution is taken out and cleaned with deionized water, and dried at 60° C. to obtain a zirconia precursor nanotube film containi...

Embodiment 2

[0030] (1) Weigh 5mg of methyl orange, dissolve it in 1L of deionized water, stir well to obtain a methyl orange solution with a concentration of 5mg / L, and adjust the pH of the methyl orange solution to 3 with sulfuric acid.

[0031] (2) get the 4cm that example 1 makes 2 The zirconia-titanium dioxide composite nanotube photocatalytic film containing an anodic alumina template was added to the beaker containing the 6mL solution of the above step 1, stirred from time to time with a magnetic stirrer, and irradiated under an ultraviolet lamp with a main wave at 254nm.

[0032] (3) Start timing for photocatalytic degradation, sampling and analysis every 30 minutes, and photocatalytic reaction for 180 minutes.

[0033] (4) Measure its absorbance at a wavelength of 506 nm with water as a reference in a spectrophotometer, and the concentration C of methyl orange is directly proportional to the absorbance A value. use C t / C 0 Calculation of photocatalytic degradation efficiency, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Tube wall thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com