Method for preparing anhydrous acetaldoxime

A technology of acetaldehyde oxime and acetaldehyde, which is applied in the field of preparation of anhydrous acetaldehyde oxime, can solve the problems of high separation stages in the extraction tower, incomplete extraction, large solvent consumption, etc., achieve high economic and social benefits, improve Production conditions, effects of avoiding organic solvents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

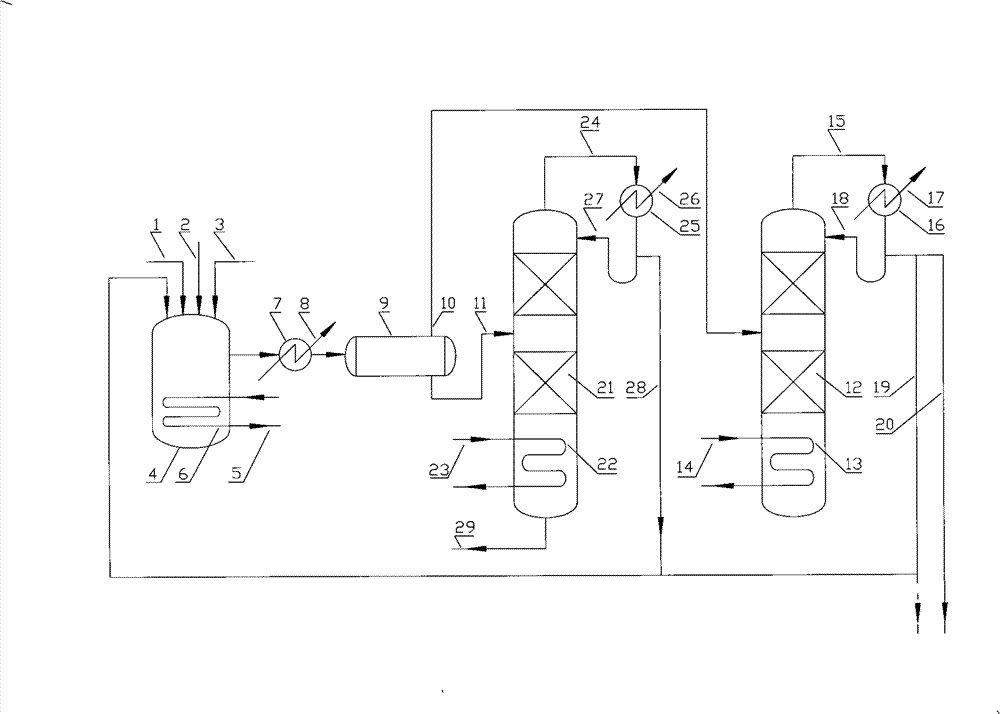

Image

Examples

Embodiment 1

[0022] The acetaldehyde oximation reactor cooled by a cooler is continuously added with hydroxylamine sulfate 6000kg / h (including hydroxylamine sulfate 780kg, sulfuric acid 525kg, ammonium sulfate 1420kg, and the rest is water) and acetaldehyde 416kg / h, which are prepared by the Raschig method. % ammonia water to control the pH value of 5.5-6.5 (about 1560kg / h), control the temperature of the acetaldehyde oximator to about 35°C, and the residence time of the reaction time to be about 0.5 hours. The overflow liquid of the acetaldehyde oximator is cooled by a cooler cooled by chilled water After reaching 7°C, it enters the liquid-liquid separator, and the lower water phase is about 7596kg / h (containing 310kg of acetaldehyde oxime, about 2920kg of ammonium sulfate, and the rest is water). 620kg of aldoxime aqueous solution, the tower kettle is about 42% ammonium sulfate aqueous solution without acetaldehyde oxime, the upper oil phase of the liquid-liquid separator is 380kg (contai...

Embodiment 2

[0024] The acetaldehyde oximation reactor with cooler is continuously added with 5500kg / h of hydroxylamine sulfate prepared by the Raschig method (including 780kg of hydroxylamine sulfate, 525kg of sulfuric acid, 1420kg of ammonium sulfate, and the rest is water), 416kg / h of acetaldehyde, rectification tower The 50% acetaldehyde oxime returned by A and rectification tower B is 2534kg / h, and 25% ammonia water is added at the same time to control the pH value of 5.5-6.5 (about 1560kg / h), and the temperature of the acetaldehyde oximator is controlled to be about 35°C, the reaction time and the residence time About 0.5 hours, the overflow liquid of the acetaldehyde oximator was cooled to 7°C by the cooler cooled by chilled water, and then entered the liquid-liquid separator. Be water) send rectifying tower B to carry out atmospheric rectification, obtain about 50% acetaldehyde oxime aqueous solution 948kg, tower still is the ammonium sulfate aqueous solution of the concentration th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com