Method for processing multi-functional multilayer ceramic capacitor

A multifunctional technology of laminated ceramic capacitors, applied in the direction of laminated capacitors, fixed capacitor parts, fixed capacitor dielectrics, etc., can solve the problem of poor transmission signal status, inability to effectively align the terminal electrodes connecting the contact surface, and resistance value change etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

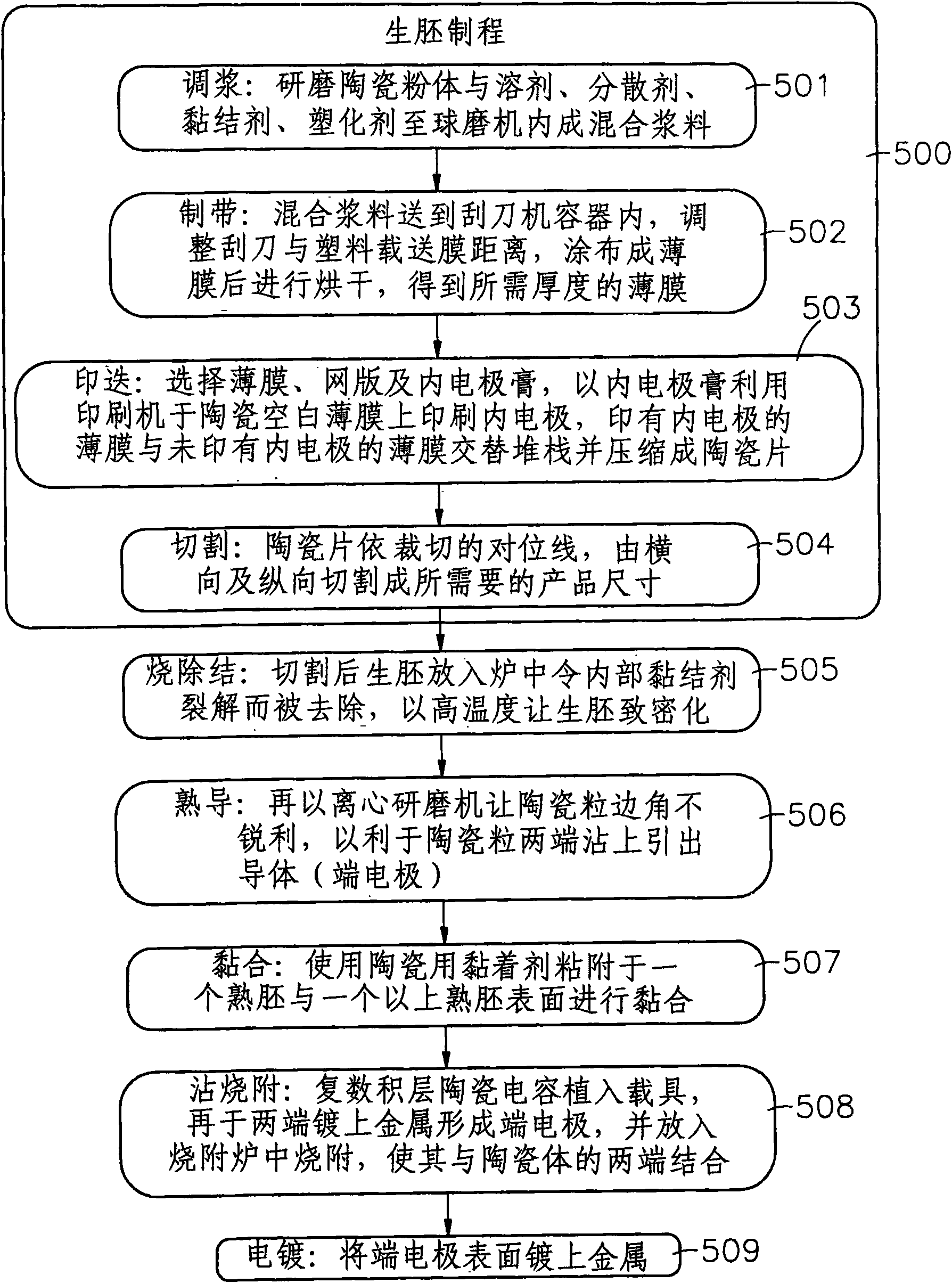

[0042] The following examples are used in conjunction with illustrations, and the detailed description is as follows.

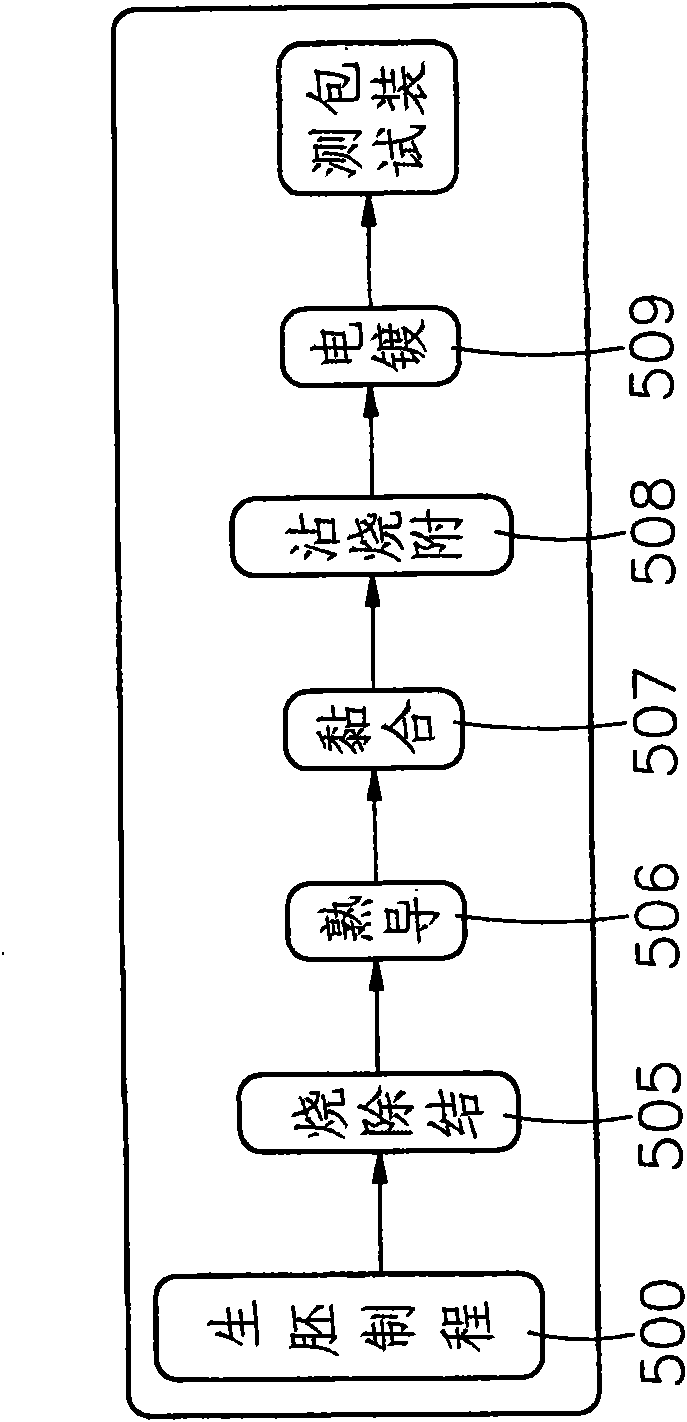

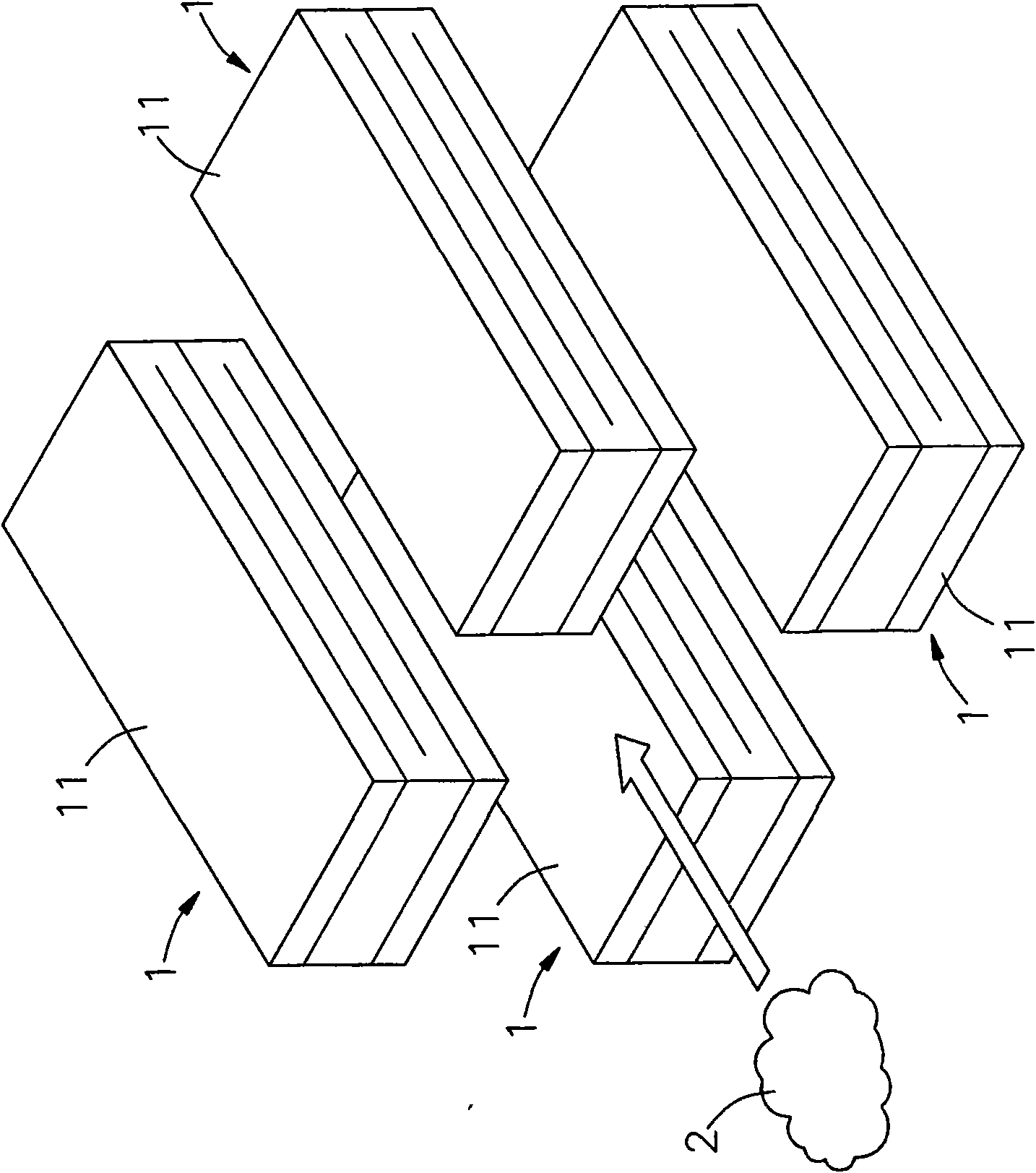

[0043] see figure 1 , figure 2As shown, it is a block diagram and a process flow chart of a preferred embodiment of the present invention. It can be clearly seen from the figure that the main steps of the multifunctional multilayer ceramic capacitor process method of the present invention are: Process 500, burning and debonding, cooking, bonding, dipping and firing, and electroplating procedures, after which the cooked embryo product is tested and packaged; each process is carried out according to the following steps:

[0044] (501) Slurry mixing: Grinding ceramic powder, solvent, dispersant, binder, plasticizer into a ball mill to form a mixed slurry.

[0045] (502) Tape making: the mixed slurry is sent to the container of the scraper machine, the distance between the scraper and the plastic carrier film is adjusted, and the film is coated and dried to ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com