Wireless network control system and method of linear cutting equipment

A technology of wireless network control and wire cutting, applied in the direction of total factory control, total factory control, electrical program control, etc., can solve problems such as burning, short service life, susceptibility to lightning strikes and strong electric interference, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

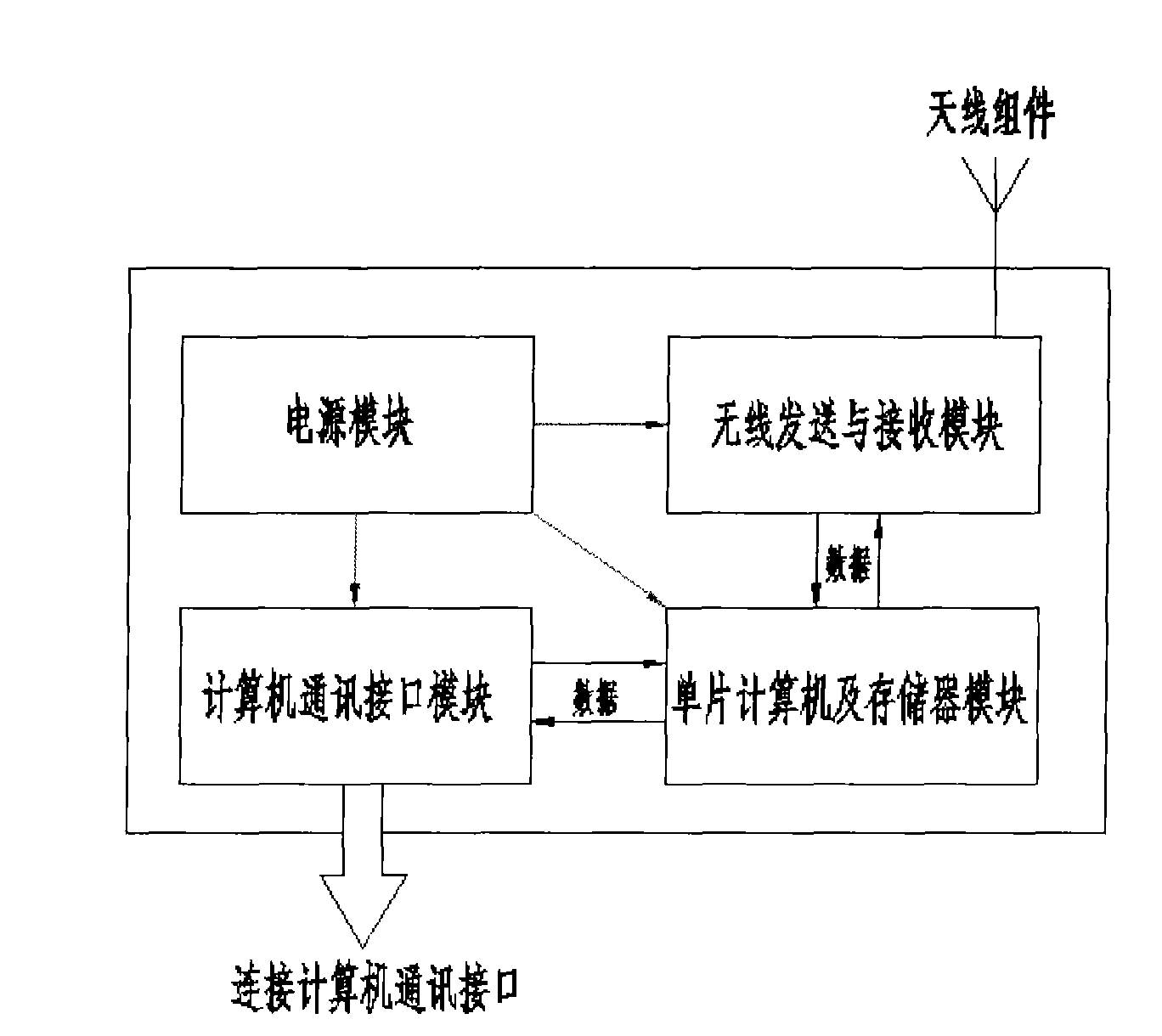

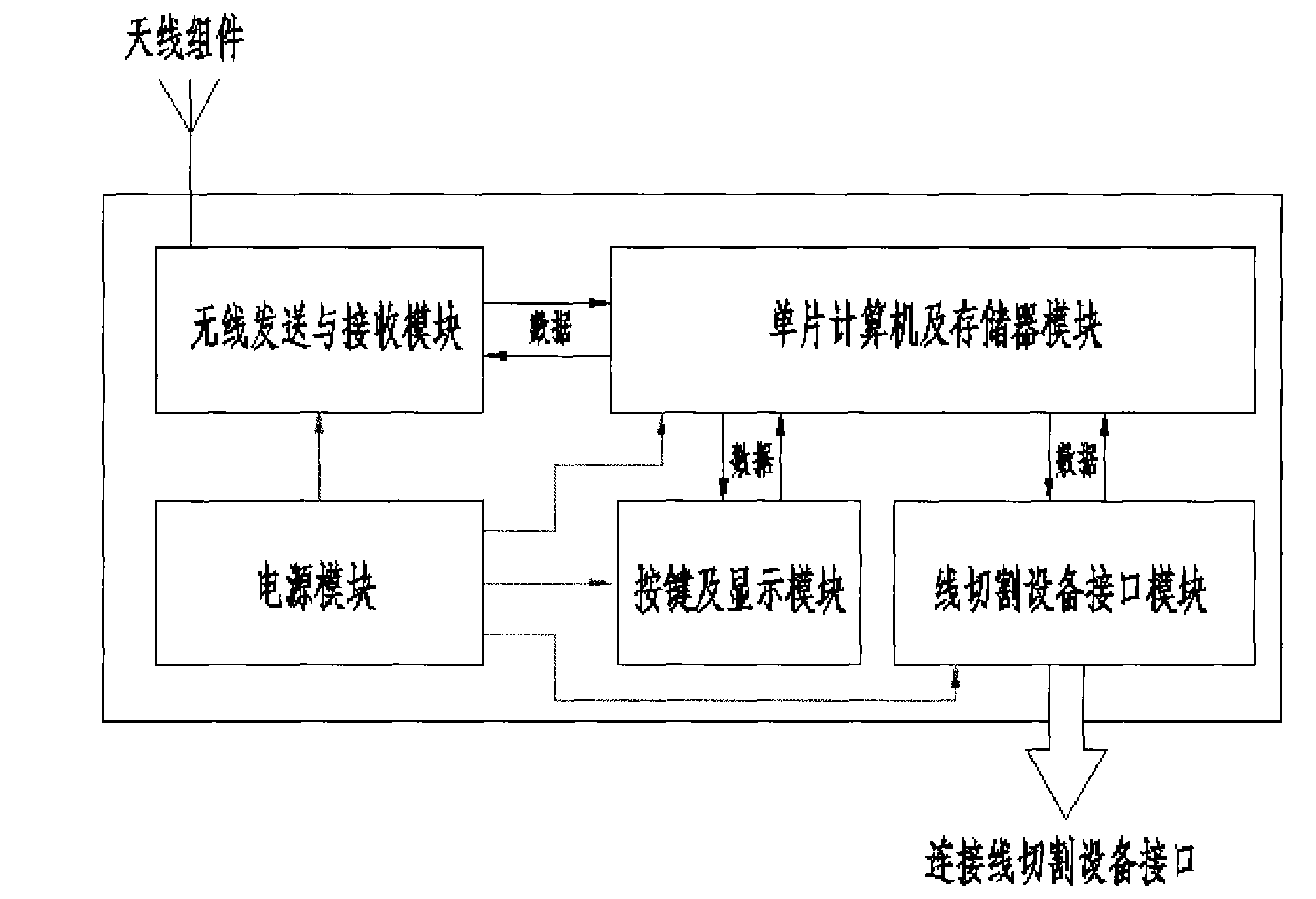

[0019] Embodiment 1: with reference to attached figure 1 and 2. Wire cutting equipment wireless network control system, which includes a computer and wire cutting equipment, the computer is connected to the wireless group control communication controller through the interface, the wire cutting equipment is connected to the wireless terminal control device, and the connection between the wireless group control communication controller and the wireless terminal control device Indirect wireless data transmission, the data transmission may be programs, instructions and control information, and the data includes terminal address information for communication with designated devices. A wireless group control communication controller can support one or more wireless terminal control devices. The wireless group control communication controller is composed of a power supply module, a single-chip computer and a memory module, a computer communication interface module, a wireless trans...

Embodiment 2

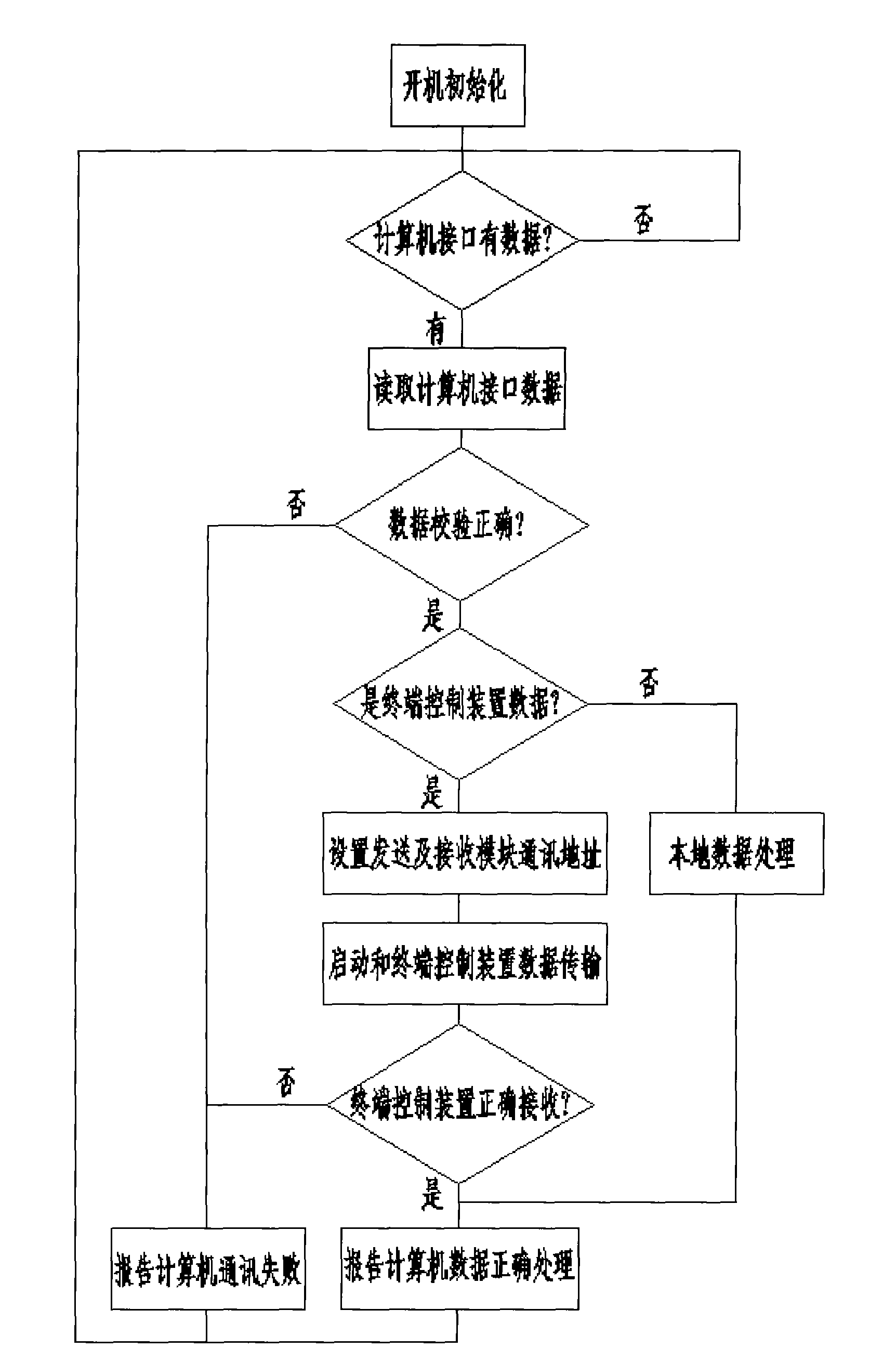

[0020] Embodiment 2: On the basis of Embodiment 1, the control method of the wireless network control system of the wire cutting equipment, which includes a built-in software program, the wireless group control communication controller and the computer are connected through an interface, the wireless terminal control device and the wire cutting equipment Connection, there is no electrical connection between the wireless group control communication controller and the wireless terminal control device, a wireless group control communication controller can support one or more wireless terminal control devices, when the computer needs to transmit data with a certain wire cutting equipment The data contains the address information of the terminal communicating with the specified device, and the data is transmitted to the wireless group control communication controller through the computer interface, and the wireless group control communication controller transmits the data to the wire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com