Method for preparing super absorbent resin containing covalent nitrogen by using potato starch as raw material

A technology of potato starch and superabsorbent resin, which is applied in the field of preparing superabsorbent resin containing covalent nitrogen elements, which can solve the problems of low gel strength, complex production process, small variety and quantity, etc., achieve good performance and improve soil fertility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

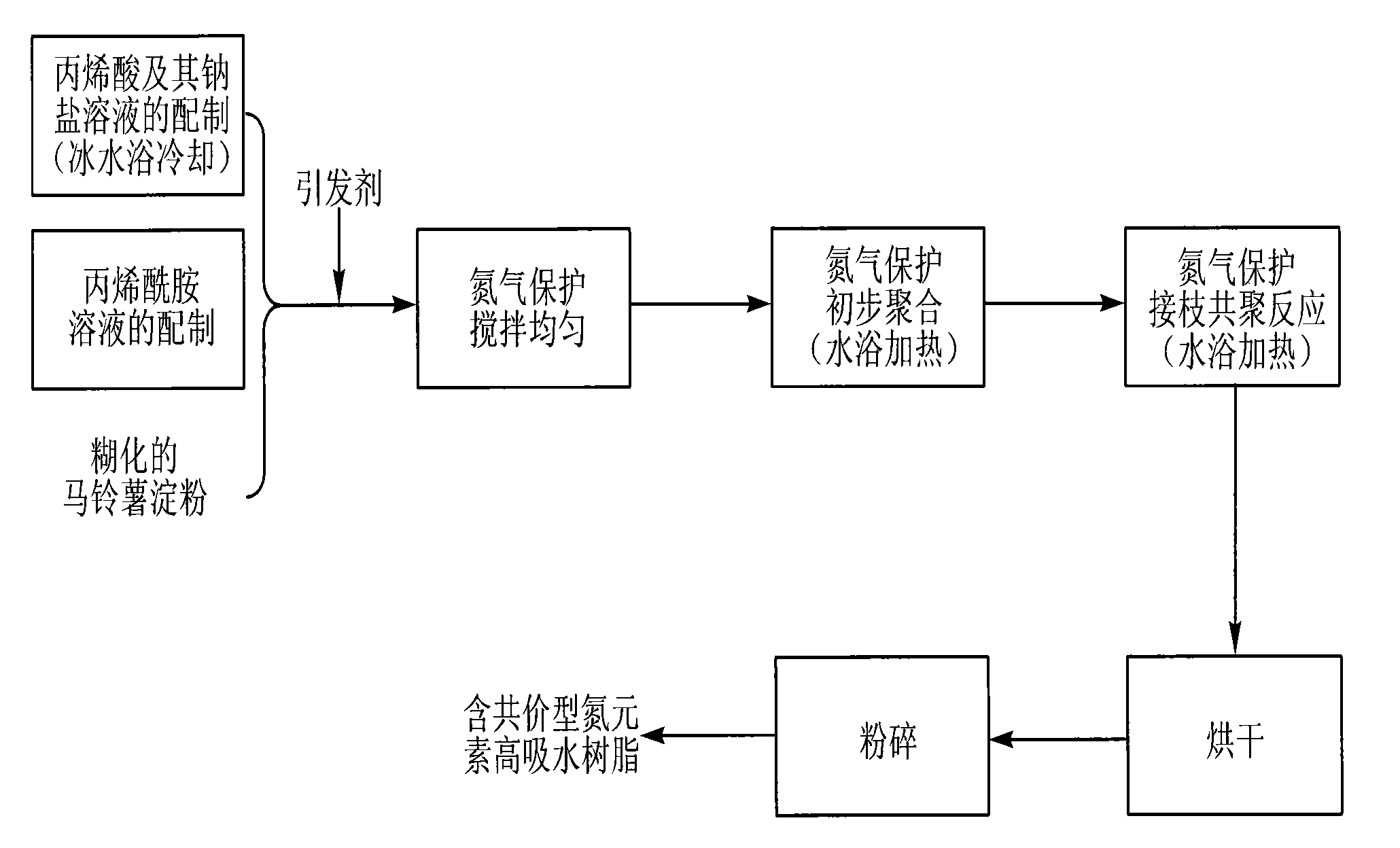

Method used

Image

Examples

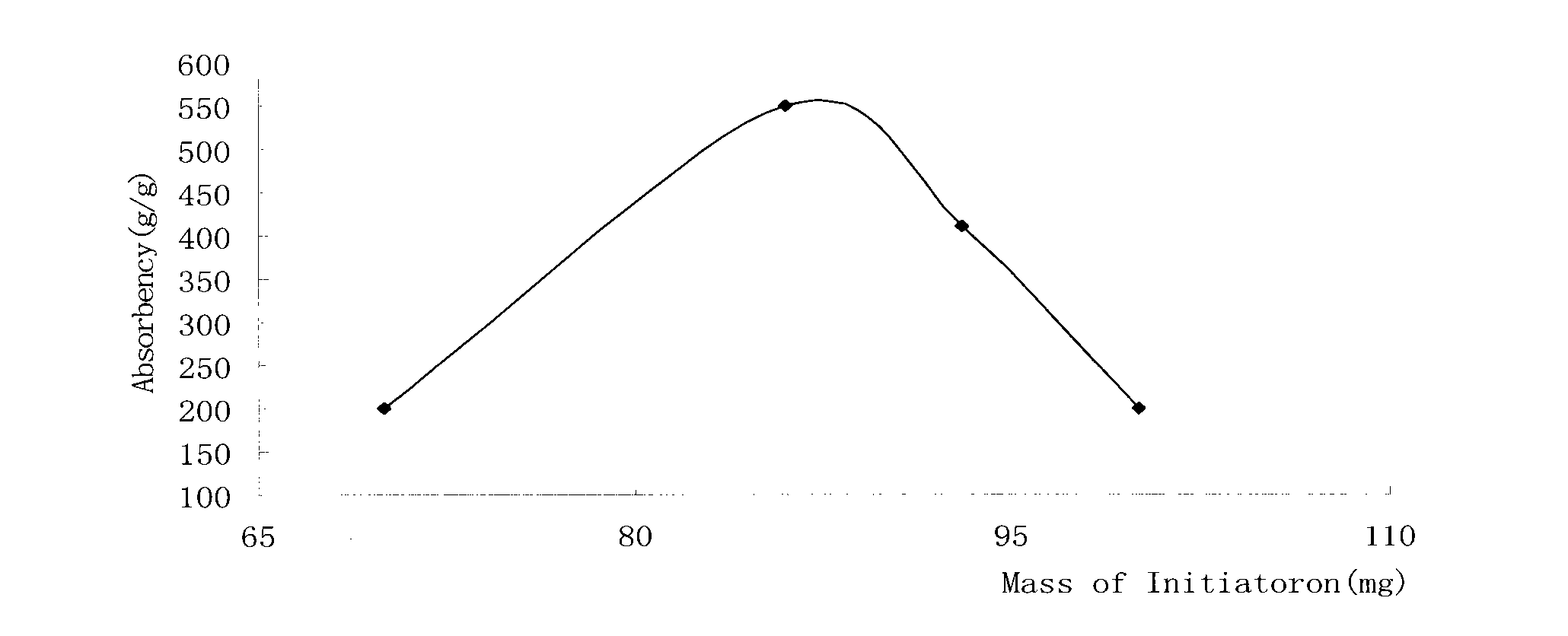

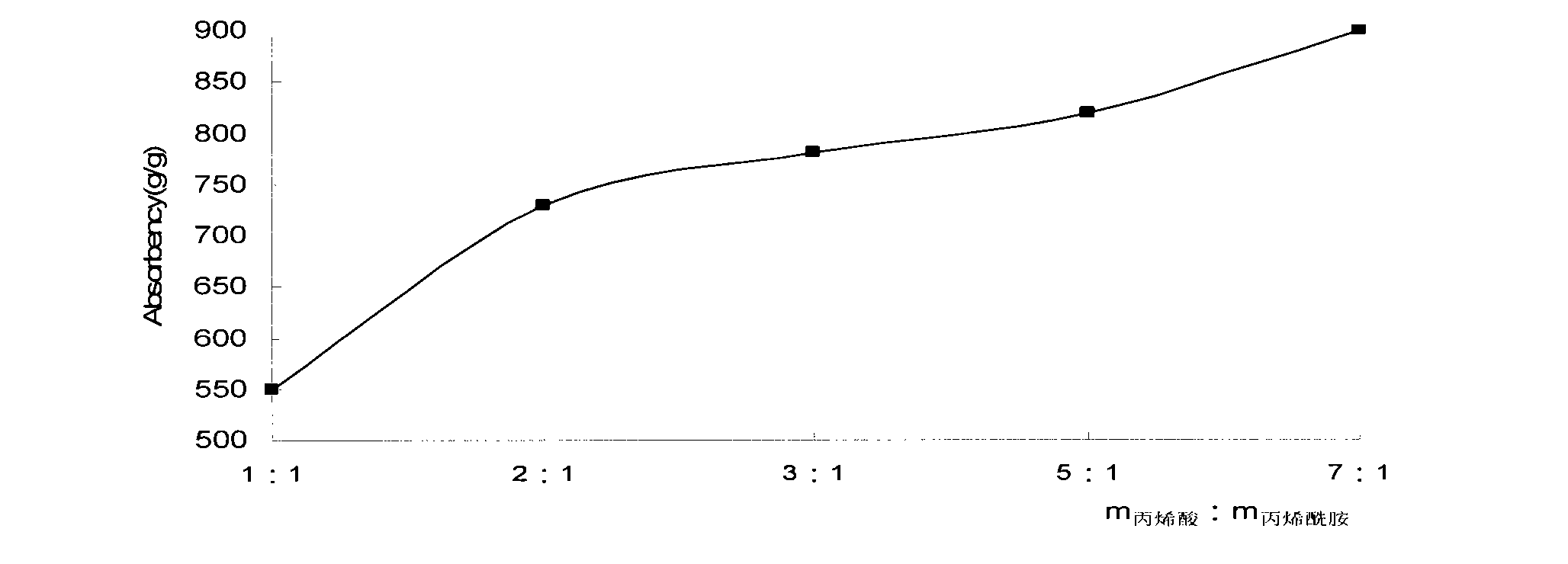

Embodiment 1

[0021] Embodiment 1: take by weighing 3.8g sodium hydroxide, measure and take 11.4ml deionized water, be made into the sodium hydroxide solution that concentration is 25%. Under the conditions of ice-water bath cooling and stirring, neutralize 22.5g (21.5ml) of the acrylic acid that removes the polymerization inhibitor. Weigh 7.5g of acrylamide and 8ml of deionized water to prepare a solution. Weigh 5.0 g of potato starch and 25.0 ml of deionized water, mix evenly under stirring conditions, and gelatinize the potato starch under heating (60°C-70°C). Stir 86g of potassium persulfate, gelatinized potato starch, acrylic acid and its sodium salt solution, and acrylamide solution at room temperature for 0.5 h under nitrogen protection, so that the reactants are evenly mixed. Heating under stirring, controlling the heating rate, increasing the temperature of the water bath slowly, so that the graft copolymerization reaction is fully carried out, and stopping stirring when the tempe...

Embodiment 2

[0022] Embodiment 2: take by weighing 2.5g sodium hydroxide, measure and take 7.5ml deionized water, be made into the sodium hydroxide solution that concentration is 25%. Under the conditions of ice-water bath cooling and stirring, neutralize 22.5g (21.5ml) of the acrylic acid that removes the polymerization inhibitor. Weigh 7.5g of acrylamide and 8ml of deionized water to prepare a solution. Weigh 5.0 g of potato starch and 25.0 ml of deionized water, mix evenly under stirring conditions, and gelatinize the potato starch under heating (60°C-70°C). Stir 86g of potassium persulfate, gelatinized potato starch, acrylic acid and its sodium salt solution, and acrylamide solution at room temperature for 0.5 h under nitrogen protection, so that the reactants are evenly mixed. Heating under stirring, controlling the heating rate, increasing the temperature of the water bath slowly, so that the graft copolymerization reaction is fully carried out, and stopping stirring when the temper...

Embodiment 3

[0023] Embodiment 3: take by weighing 5.0g sodium hydroxide, measure and take 15.0ml deionized water, be made into the sodium hydroxide solution that concentration is 25%. Under the conditions of ice-water bath cooling and stirring, neutralize 22.5g (21.5ml) of the acrylic acid that removes the polymerization inhibitor. Weigh 7.5g of acrylamide and 8ml of deionized water to prepare a solution. Weigh 5.0 g of potato starch and 25.0 ml of deionized water, mix evenly under stirring conditions, and gelatinize the potato starch under heating (60°C-70°C). Stir 86g of potassium persulfate, gelatinized potato starch, acrylic acid and its sodium salt solution, and acrylamide solution at room temperature for 0.5 h under nitrogen protection, so that the reactants are evenly mixed. Heating under stirring, controlling the heating rate, increasing the temperature of the water bath slowly, so that the graft copolymerization reaction is fully carried out, and stopping stirring when the tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com