Washing agent for separation membrane, process for producing the same and method of washing

A manufacturing method and separation membrane technology, applied in the field of cleaning agents, can solve the problems of long cleaning time, harmful trihalomethanes, insufficient cleaning, etc., and achieve the effects of shortening cleaning time, reducing water consumption, and high cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

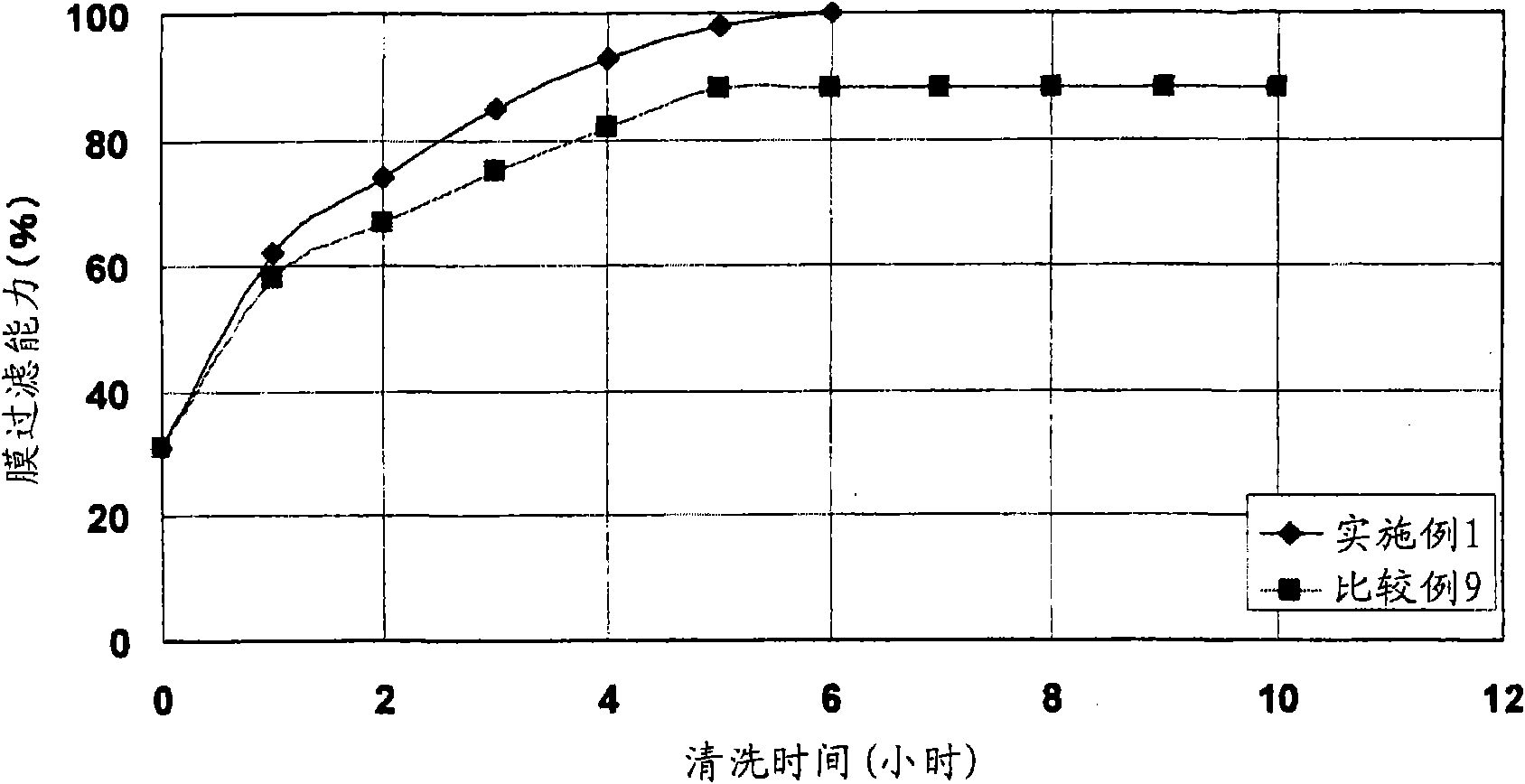

[0059] As raw water, use water with a turbidity of about 1 to 5 degrees (measured using a kaolin standard solution manufactured by Kanto Chemical Co., Ltd. as a reference) and a total organic carbon (TOC) of 0.5 mg / L to 1.5 mg / L. For surface water in rivers, the membrane modules that have been in operation for 6 months and have a differential pressure between the membranes of 200kPa are cleaned as described later.

[0060] As a cleaning solution, use a hydrogen peroxide aqueous solution (0.88mol / L) to mix ferrous chloride and malic acid so that the concentration of ferrous chloride is 0.0008mol / L and the concentration of malic acid is 0.05mol / L. The prepared cleaning solution was circulated and filtered for 6 hours. Thereafter, the cleaning solution was removed from the module, and the separation membrane was washed with 500 liters of UF filtered water for 2.5 hours as a rinsing step.

[0061] As a result of cleaning by the above-mentioned cleaning method, when the filtration...

Embodiment 2

[0064] When cleaning the polluted membrane module of embodiment 1, as cleaning liquid, use in the aqueous solution (0.88mol / L) of hydrogen peroxide, mix ferrous chloride and tartaric acid and make the concentration of ferrous chloride be 0.0008mol / L, The concentration of tartaric acid is 0.05mol / L and the cleaning liquid prepared, carries out 6 hours circulation filter cleaning. Thereafter, the cleaning solution was removed from the module, and the separation membrane was washed with 500 liters of UF filtered water for 2.5 hours as a rinsing step.

[0065] As a result of cleaning by the above-mentioned cleaning method, when the filtration capacity of the membrane when not in use is 100%, the filtration capacity of the membrane which was reduced to 10% before cleaning returns to 100% after cleaning. The total cleaning time in this cleaning method was 8.5 hours. Also, generation of chlorine gas and heat of reaction were not observed.

[0066] Filtration operation was performed...

Embodiment 3

[0068] When cleaning the polluted membrane module of embodiment 1, as cleaning liquid, use the aqueous solution (0.88mol / L) of hydrogen peroxide to mix ferrous chloride and tartronic acid and make the concentration of ferrous chloride be 0.0008mol / L, the concentration of tartronic acid is 0.05mol / L and the cleaning solution prepared is carried out 6 hours of circulating filtration cleaning. Thereafter, the cleaning solution was removed from the module, and the separation membrane was washed with 500 liters of UF filtered water for 2.5 hours as a rinsing step.

[0069] As a result of cleaning by the above-mentioned cleaning method, when the filtration capacity of the membrane when not in use is 100%, the filtration capacity of the membrane which was reduced to 10% before cleaning returns to 100% after cleaning. The total cleaning time in this cleaning method was 8.5 hours. Also, generation of chlorine gas and heat of reaction were not observed.

[0070] Filtration operation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com